Contact Us To Get The Hot Product Catalog

We are constantly exploring products tailored for the structural steel pipe market.

Here, you will find a unique product line designed specifically for the global market that pursues excellence and quality, aimed at meeting your various needs. Our goal is to become a leading global manufacturer of structural steel pipes, providing every customer with the high-quality products and services they expect.

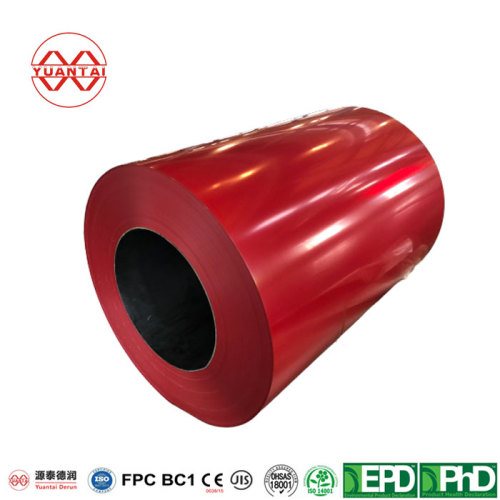

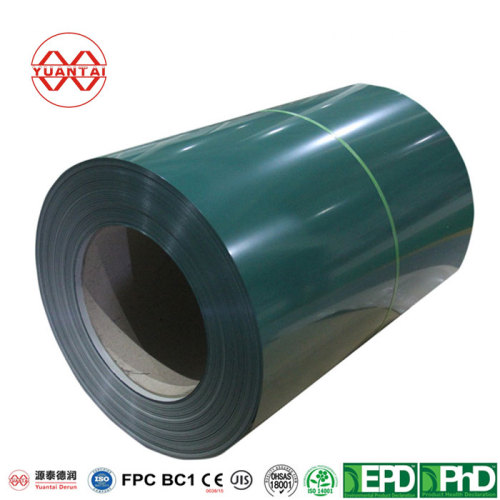

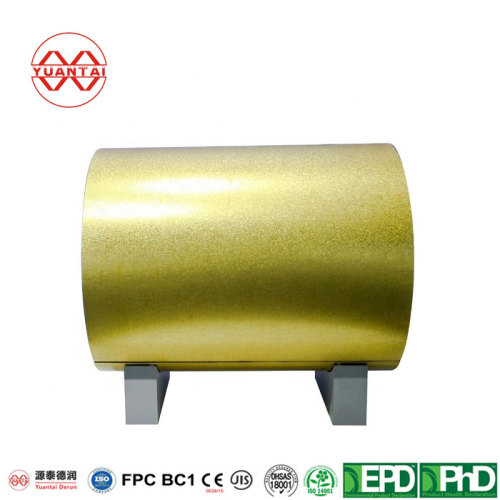

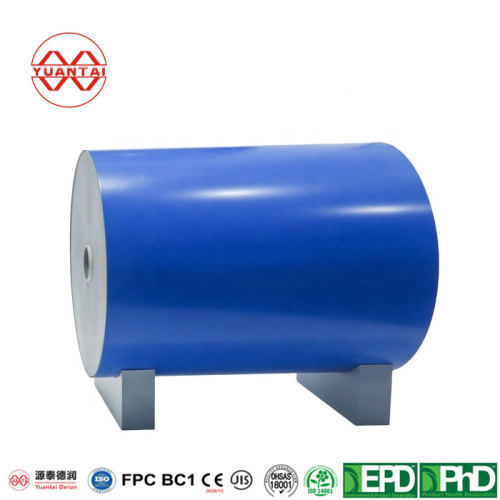

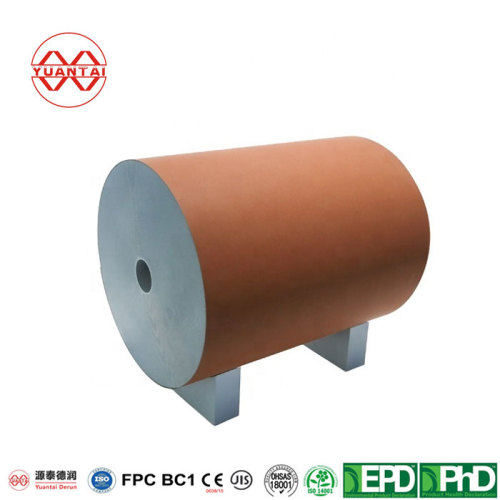

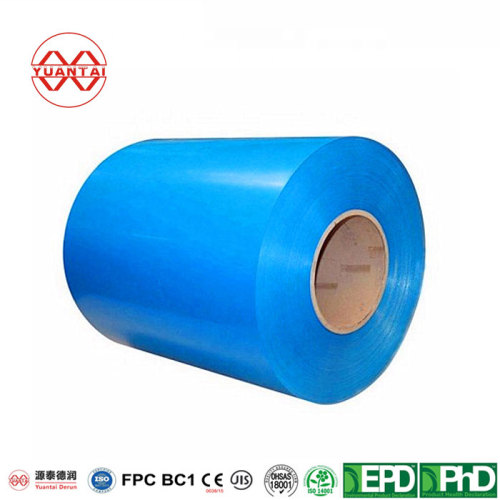

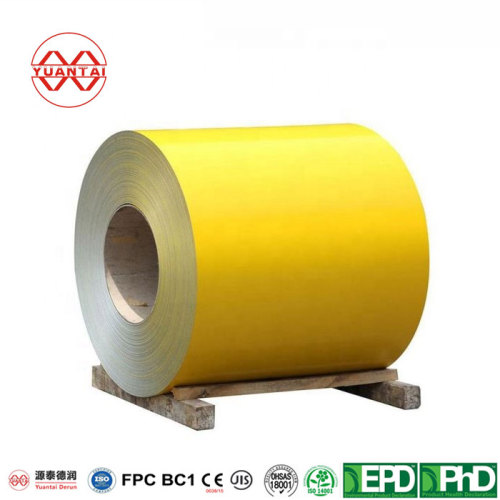

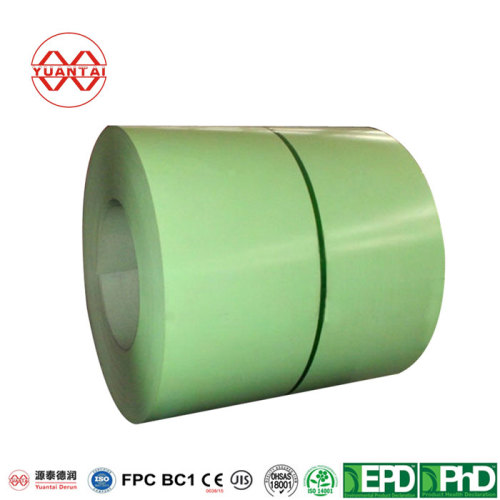

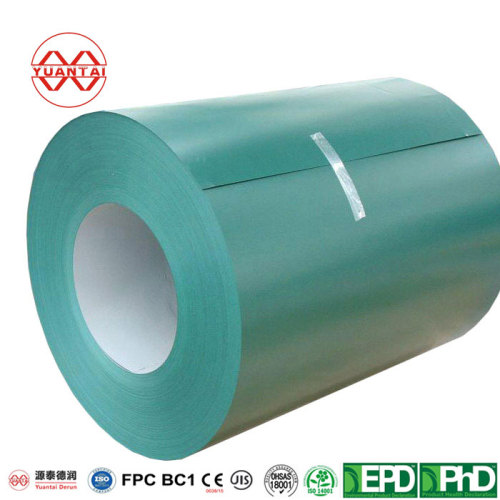

PPGI coil

PPGI coil, also known as pre coated steel, coil steel, and color coated steel, represents pre coated galvanized iron. Galvanized steel coil can be obtained by continuous hot dipping to form a high-purity zinc coating. The galvanized steel coil serves as the substrate for the color coated coil, and its galvanized coating provides cathodic and barrier protection for the base steel. PPGI is painted on galvanized steel coils because it can significantly reduce the corrosion rate of the zinc layer. PPGI steel coils with multi-layer anti-corrosion systems can be used in corrosive outdoor structures for a long time.

PPGI steel coils come in a variety of vibrant colors and patterns. Yuantai Derun provides PPGI coils produced by a Chinese made PPGI steel coil factory. These products comply with various international standards to meet the needs of different markets.

Advantage

Aesthetic performance: PPGI steel coils have rich colors and textures, smooth and flat surfaces, and good decorative effects.

Corrosion resistance: The surface coating of the PPGI coil has excellent corrosion resistance and can be used for many years in harsh environments without damage.

Weather resistance: It can resist the erosion of natural environments such as sunlight, rain, and wind, and maintain a long-term stable appearance.

Mechanical performance: It has high mechanical strength and stiffness, and can withstand the load of building structures and mechanical equipment.

Processing performance: It can be processed through cold bending, stamping, shearing, and welding, and has good processing performance and formability.

Anti peeling property: The colored coating of the PPGI steel coil has strong adhesion and is not easy to peel off, which can protect the zinc layer for a long time.

Good wear resistance: The outer color coating of the PPGI coil has excellent wear resistance and is not easily worn off by external forces.

Characteristic

|

Thickness(mm)

|

0.13mmto 2.0 mm

|

Coating thickness

|

15 to 40 microns

|

|

Width(mm)

|

600-1250mm

|

Weight/Coil

|

Less Than 4.5 Tons per coil

|

|

Standard

|

ASTM a755/755M,EN10169,JIS 3312: SGCC, SGCD, SGCH, CGCC, SPCC,GB/T 12754,IS 14246,etc

|

Color Or motifs

|

Based on catalogs or customized requests

|

|

Zinc Coating

|

40 to 275 gsm

|

Paint System

|

Epoxy resins, fluorocarbon coatings, PVDF (polyvinylidene fluoride) coatings, powder coatings

|

Finishes | Smooth, matt, high gloss, textures, printed | Package | Standard |

Delivery Conditions | Coil form | MEK | ≥100 |

PPGI Coil Making Process

The PPGI coil making process has those main step:

1. Uncoiling->2 Trimming ->3 Surface pretreatment ->4 Primer coverage ->5 Topcoat coverage ->6 Baking and curing ->7. Cooling ->8. Quality inspection ->9. Winding ->10 packing

Application

PPGI coils are used for many industries ,such as:

Activity roomFence enclosure

Roof and cladding

building

transport

Refrigerator

Air conditioning package

Washing machine

solar energy

furniture

17 products found

ViewShowcase

ppgi coil manufacturer in india,complete specifications with high quality and low price

Pre-Painted Wrinkle Steel Coils (MATT)(can oem odm obm)complete specifications with high quality and low price

China ppgi roofing sheet wholesale factory(OEM ODM OBM)yuantaiderun complete specifications with high quality and low price

Yuantai Derun produces 32/1000 Box Profile 0.7 PVC Plastisol Coated Roof Sheet Metal, factory direct supply.

Yuantai Derun group produces prepainted galvanized steel coil, accept oem odm obm or Can customiz,high quality and low price

PPGI coil supplier yuantaiderun(can oem odm obm or Can customize),low cost,high quality.

Wholesale customization PPGI coil China supplier yuantaiderun,high quality,low price,complete specifications,fast delivery.

ppgi coil dealers in mumbai(can oem odm obm) with high quality and low price

PPGI steel coil manufacturer yuantaiderun(can oem odm obm)with high quality and low price

ppgi steel coil manufacturers China yuantaiderun(accept oem odm obm) with high quality and low price

China PPGI steel coil supplier Tianjin YuantaiDerun,high quality,low price,also accept oem odm obm or customize

yuantaiderun can produce ppgi steel coil thailand (accept oem odm obm) with high quality and low price

Categories

- square steel pipe

- rectangular steel pipe

- round steel pipe

- shaped tube

- LSAW steel pipe

- zinc aluminium magnesium coating steel pipe

- galvanized steel pipe

- ERW steel pipe

- seamless steel pipe

- spiral steel pipe

- LINE PIPE&OCTG

- stainless steel pipe

- steel coil

- steel plate

- ship building steel pipe

- photovoltaic bracket

- steel profile

- Steel Pipe

- Steel Profile

- Steel Coil

- USE

- Structural steel pipe

- Fluid pipe

- Shape

- Square steel pipe

- Rectangular steel pipe

- Round steel pipe

- Shape tube

- Turface Treatment

- Black steel tube

- Pre galvanzied steel tube

- Hot dip galvanized steel tube

- Zinc aluminum magnesium coating steel tube

- Material

- Carbon steel pipe

- Alloy steel pipe

- Stainless steel pipe

- Standard

- EN10210

- EN10219

- ASTM A500

- ASTM A501

- ASTM A53

- ASTM A106

- ASTM A572

- ASTM A992

- JIS G3466

- AS/NZS 1163

- CSA G40.20

- CSA G40.21

- API 5L

- API 5CT

- Molding Process

- ERW steel pipe

- LSAW steel pipe

- Spiral welded steel pipe

- Seamless steel pipe

- Sales Attributes

- Sample list

- OEM

- ODM

- New arrival

- Basic style

- Star style

- Cross Section

- C channel

- Z channel

- U channel

- Round steel rod

- Rebar

- Angle steel

- H beam

- Raw material

- carbon steel profile

- Stainless steel profile

- Alloy steel profiles

- Surface Treatment

- Zinc aluminum magnesium steel coil

- GI steel coil

- PPGI coil

- Stainless steel coil

- Steel plate

- Steel strip

subscription

Please send your message to us

Yuantai team has over 21 years of experience in steel pipe project applications, specializing in the production, manufacturing, and customization of square rectangular, and circular steel pipes. Warmly welcome project procurement managers, individual owners, designers, and overall sellers, etc. Write down your requirements and receive professional quotes and technical support.

- Name

- Tel

- *Title

- *Content