Polypropylene 3PP anti-corrosion spiral welded steel pipe

Detail Information

Polypropylene 3PP Anti-Corrosion Spiral Welded Steel Pipe

Polypropylene 3PP anti-corrosion spiral steel pipe is a spiral welded steel pipe with three types of anti-corrosion coatings, also known as 3PP steel pipe. At present, the polypropylene 3PP anti-corrosion spiral steel pipes supplied by Yuantai Derun are produced according to the German standard DIN30678. The main advantages are strong anti-corrosion ability and high temperature resistance. Often used in pipeline systems in desert areas.

Coating Structure

Polypropylene 3PP Anti-Corrosion Spiral Welded Steel Pipe have 3 coating layer,3PP anti-corrosion refers to the three-layer PP anti-corrosion structure of pipelines:

The first layer of epoxy powder (FBE),

Second layer adhesive (AD),

The third layer of polyethylene (PP).

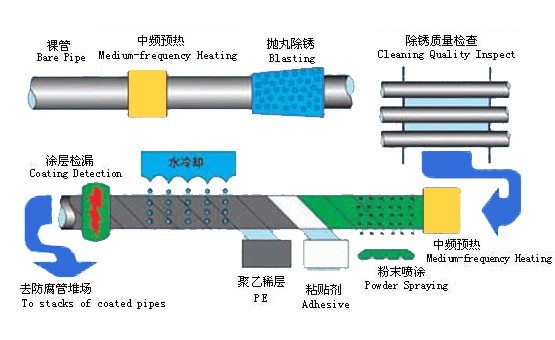

3PP Spiral Steel Pipes Making Process

3PP Spiral Steel Pipes Making Process mainly including those steps:

bare spiral welded steel pipe->Intermediate frequency preheating->Shot blasting rust removal->Rust removal quality inspection->Intermediate frequency preheating->Powder coating->Adhesive->Polyethylene layer->water cooling->Coating inspection->3PP anti-corrosion pipe storage

3PP Spiral Steel Pipes Making Process mainly including those steps:

bare spiral welded steel pipe->Intermediate frequency preheating->Shot blasting rust removal->Rust removal quality inspection->Intermediate frequency preheating->Powder coating->Adhesive->Polyethylene layer->water cooling->Coating inspection->3PP anti-corrosion pipe storage

Application Of 3PP Steel Pipe

3PP steel pipe is mainly used for those industries.3PP coated spiral welded pipes are mainly used for transporting high-temperature media and for pipeline laying in desert areas with high surface temperatures and long sunshine hours. Therefore, they have been increasingly widely used in buried water, gas, and oil pipelines in areas with high surface temperatures and long sunshine hours.

Review

- Loading...

Related Products

Please send your message to us

Yuantai team has over 21 years of experience in steel pipe project applications, specializing in the production, manufacturing, and customization of square rectangular, and circular steel pipes. Warmly welcome project procurement managers, individual owners, designers, and overall sellers, etc. Write down your requirements and receive professional quotes and technical support.

- Name

- Tel

- *Title

- *Content

Categories

- square steel pipe

- rectangular steel pipe

- round steel pipe

- shaped tube

- LSAW steel pipe

- zinc aluminium magnesium coating steel pipe

- galvanized steel pipe

- ERW steel pipe

- seamless steel pipe

- spiral steel pipe

- LINE PIPE&OCTG

- stainless steel pipe

- steel coil

- steel plate

- ship building steel pipe

- photovoltaic bracket

- steel profile

subscription

Please send your message to us

Yuantai team has over 21 years of experience in steel pipe project applications, specializing in the production, manufacturing, and customization of square rectangular, and circular steel pipes. Warmly welcome project procurement managers, individual owners, designers, and overall sellers, etc. Write down your requirements and receive professional quotes and technical support.

- Name

- Tel

- *Title

- *Content