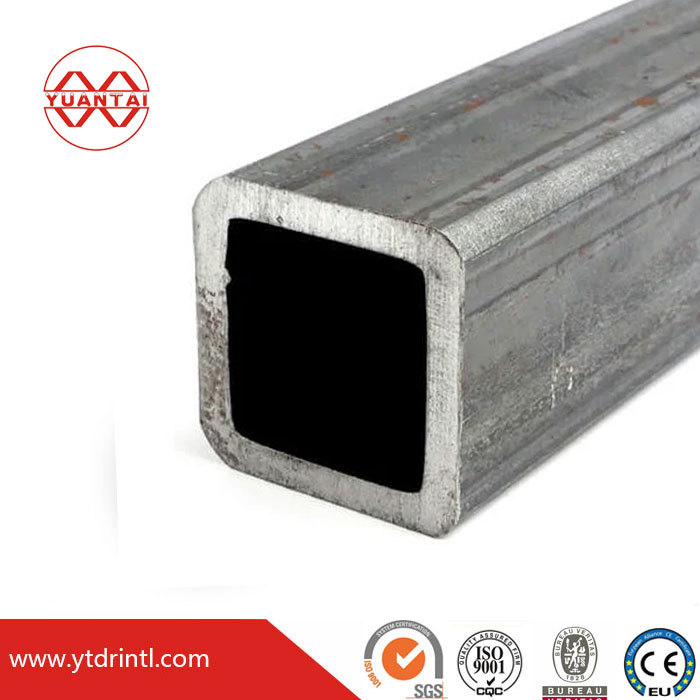

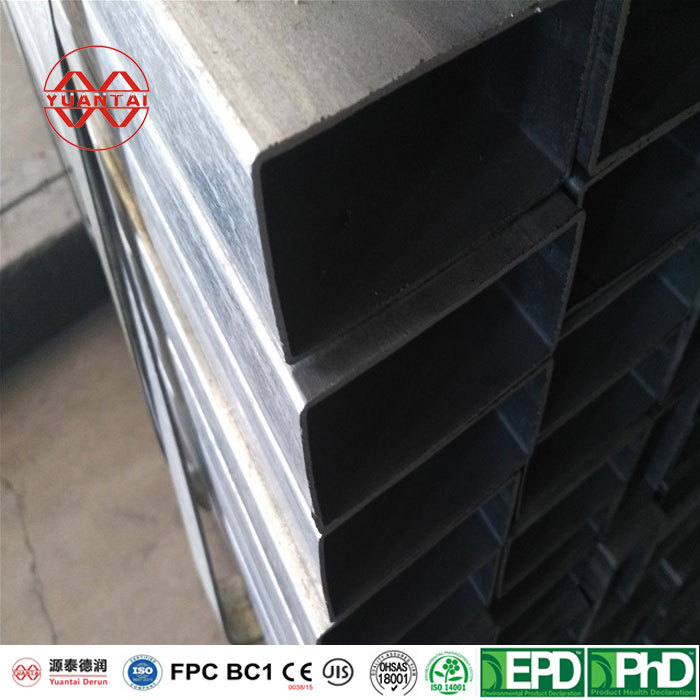

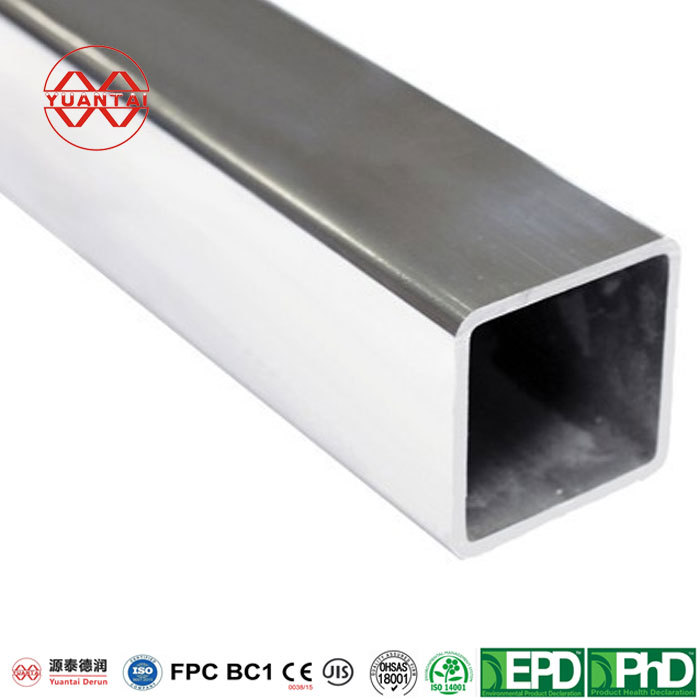

Leading Carbon Steel Pipe Manufacturer: Galvanized Rectangular Schedule 40 MS Steel Tube

Leading Carbon Steel Pipe Manufacturer: Galvanized Rectangular Schedule 40 MS Steel Tube

3.1 Definition and characteristics of carbon steel pipes

3.3 Manufacturing process of carbon steel pipes

1. Raw Material Preparation 2. Heating 3. Forming 4.Welding (for welded pipes) 5. Sizing 6. Heat Treatment 7. Finishing Operations 8. Inspection and Testing 9. Packing and Shipping

3.4 Types of carbon steel pipes

There are several types of carbon steel pipes commonly used in various industries. Here are a few examples:

Seamless Carbon Steel Pipes: These pipes are manufactured without any seams or welded joints, resulting in a smooth and uniform surface. They are often used in high-pressure applications such as oil and gas industry, refineries, and chemical plants.

Welded Carbon Steel Pipes: As the name suggests, these pipes are made by welding two pieces of carbon steel together. They are available in various forms such as ERW (Electric Resistance Welded), EFW (Electric Fusion Welded), and LSAW (Longitudinal Submerged Arc Welded). Welded pipes are commonly used in structural and plumbing applications.

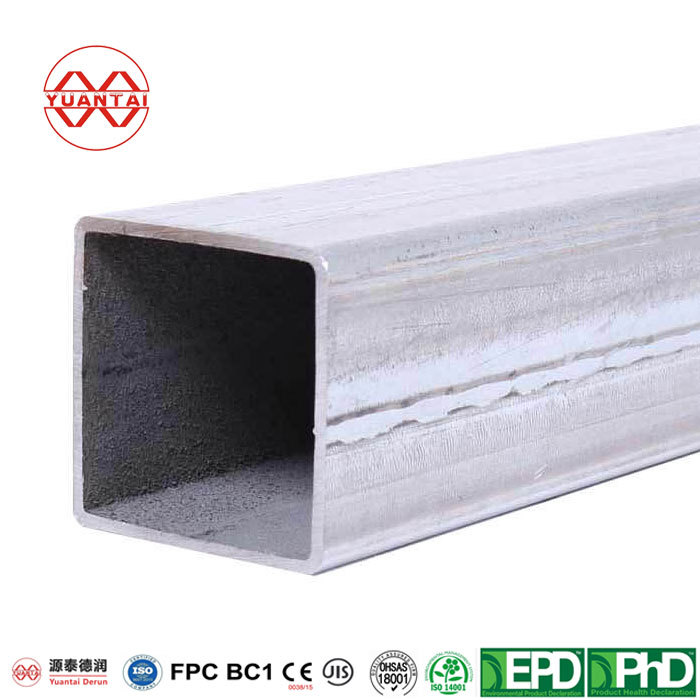

Galvanized Carbon Steel Pipes: These pipes are coated with a layer of zinc to protect against corrosion. The zinc coating is applied either by hot-dip galvanizing or electroplating. Galvanized carbon steel pipes are widely used in outdoor applications, water supply systems, and construction projects.

High Yield Carbon Steel Pipes: These pipes are manufactured with higher carbon content, typically above 0.55%. They have superior strength and toughness, making them suitable for demanding applications in the oil and gas industry and structural engineering.

Low Carbon Steel Pipes: Also known as mild steel pipes, these pipes have a lower carbon content compared to other types of carbon steel pipes. They are versatile and commonly used in general-purpose applications such as water transportation, plumbing, and HVAC systems.

Carbon Steel ERW Pipes: Electrical Resistance Welded pipes are made by rolling a flat steel plate and welding the edges together. They are commonly used in low to medium-pressure applications such as water and gas supply systems.

O.D. mm | W.T.mm | O.D mm | W.T. mm | O.D mm | W.T. mm | O.D mm | W.T. mm |

20*20 | 1.3 | 60*120 80*100 90*90 | 1.50 | 180*180 | 3 | 300*800 400*700 550*550 500*600 | |

1.4 | 1.70 | 3.5-3.75 | 9.5-9.75 | ||||

1.5 | 1.80 | 4.5-4.75 | 11.5-11.75 | ||||

1.7 | 2.00 | 5.5-7.75 | 12-13.75 | ||||

1.8 | 2.20 | 9.5-9.75 | 15-50 | ||||

2.0 | 2.5-4.0 | 11.5-11.75 | | ||||

20*30 25*25 | 1.3 | 4.25-4.75 | 12.0-25.0 | | |||

1.4 | 5.0-6.3 | 100*300 150*250 200*200 | 2.75 | 300*900 400*800 600*600 500*700 | | ||

1.5 | 7.5-8 | 3.0-4.0 | 9.5-9.75 | ||||

1.7 | 50*150 60*140 80*120 100*100 | 1.50 | 4.5-9.75 | 11.5-11.75 | |||

1.8 | 1.70 | 11.5-11.75 | 12-13.75 | ||||

2.0 | 2.00 | 12.5-12.75 | 15-50 | ||||

2.2 | 2.20 | 13.5-13.75 | | ||||

2.5-3.0 | 2.5-2.75 | 15.5-30 | | ||||

20*40 25*40 30*30 30*40 | 1.3 | 3.0-4.75 | 150*300 200*250 | 3.75 | 300*1000 400*900 500*800 600*700 650*650 | | |

1.4 | 5.5-6.3 | 4.5-4.75 | | ||||

1.5 | 7.5-7.75 | 5.5-6.3 | 9.5-9.75 | ||||

1.7 | 9.5-9.75 | 7.5-7.75 | 11.5-11.75 | ||||

1.8 | 11.5-16 | 9.5-9.75 | 12-13.75 | ||||

2.0 | 60*160 80*140 100*120 | 2.50 | 11.5-11.75 | 15-50 | |||

2.2 | 2.75 | 13.5-30 | | ||||

2.5-3.0 | 3.0-4.75 | 200*300 250*250 | 3.75 | 400*1000 500*900 600*800 700*700 | | ||

3.25-4.0 | 5.5-6.3 | 4.5-4.75 | | ||||

25*50 30*50 30*60 40*40 40*50 40*60 50*50 | 1.3 | 7.5-7.75 | 5.5-6.3 | 9.5-9.75 | |||

1.4 | 9.5-16 | 7.5-7.75 | 11.5-11.75 | ||||

1.5 | 75*150 | 2.50 | 9.5-9.75 | 12-13.75 | |||

1.7 | 2.75 | 11.5-11.75 | 15-50 | ||||

1.8 | 3.0-3.75 | 12-13.75 | | ||||

2.0 | 4.5-4.75 | 15.5-30 | | ||||

2.2 | 5.5-6.3 | 200*400 250*350 300*300 | 4.5-6.3 | 500*1000 600*900 700*800 750*750 | | ||

2.5-3.0 | 7.5-7.75 | 7.5-7.75 | 9.5-9.75 | ||||

3.25-4.0 | 9.5-16 | 9.5-9.75 | 11.5-11.75 | ||||

4.25-4.75 | 80*160 120*120 | 2.50 | 11.5-11.75 | 12-13.75 | |||

5.0-5.75 | 2.75 | 12-13.75 | 15-50 | ||||

5.75-6.3 | 3.0-4.75 | 15.5-30 | | ||||

40*80 50*70 50*80 60*60 | 1.3 | 5.5-6.3 | 200*500 250*450 300*400 350*350 | 5.5-6.3 | 500*1100 600*900 700*800 800*800 | | |

1.5 | 7.5-7.75 | 7.5-7.75 | 9.5-9.75 | ||||

1.7 | 9.5-9.75 | 9.5-9.75 | 11.5-11.75 | ||||

1.8 | 11.5-20 | 11.5-11.75 | 12-13.75 | ||||

2.0 | 100*150 | 2.50 | 12-13.75 | 15-50 | |||

2.2 | 2.75 | 15.5-30 | | ||||

2.5-3.0 | 3.0-4.75 | 280*280 | 5.5-6.3 | 600*1100 700*1000 800*900 850*850 | | ||

3.25-4.0 | 5.5-6.3 | 7.5-7.75 | 9.5-9.75 | ||||

4.25-4.75 | 7.5-7.75 | 9.5-9.75 | 11.5-11.75 | ||||

5.0-6.0 | 9.5-9.75 | 11.5-11.75 | 12-13.75 | ||||

40*100 60*80 70*70 | 1.3 | 11.5-20 | 12-13.75 | 15-50 | |||

1.5 | 100*200 120*180 150*150 | 2.50 | 15.5-30 | | |||

1.7 | 2.75 | 350*400 300*450 | 7.5-7.75 | 700*1100 800*1000 900*900 | | ||

1.8 | 3.0-7.75 | 9.5-9.75 | 11.5-11.75 | ||||

2.0 | 9.5-9.75 | 11.5-11.75 | 12-13.75 | ||||

2.2 | 11.5-20 | 12-13.75 | 15-50 | ||||

2.5-3.0 | 100*250 150*200 | 3.00 | 15.5-30 | | |||

3.25-4.0 | 3.25-3.75 | 200*600 300*500 400*400 | 7.5-7.75 | 800*1100 900*1000 950*950 | | ||

4.25-4.75 | 4.25-4.75 | 9.5-9.75 | 11.5-11.75 | ||||

5.0-6.3 | 9.5-9.75 | 11.5-11.75 | 12-13.75 | ||||

50*100 60*90 60*100 75*75 80*80 | 1.3 | 11.5-11.75 | 12-13.75 | 15-50 | |||

1.5 | 12.25 | 15.5-40 | | ||||

1.7 | 140*140 | 3.0-3.75 | 300*600 400*500 450*450 | 7.5-7.75 | 900*1100 1000*1000 800*1200 | | |

1.8 | 4.5-6.3 | 9.5-9.75 | | ||||

2.0 | 7.5-7.75 | 11.5-11.75 | 20-60 | ||||

2.2 | 9.5-9.75 | 12-13.75 | | ||||

2.5-3.0 | 11.5-25 | 15.5-40 | | ||||

3.25-4.0 | 160*160 | 3.00 | 400*600 500*500 | 9.5-9.75 | 1100*1000 1200*1200 | | |

4.25-4.75 | | 3.5-3.75 | 11.5-11.75 | 20-60 | |||

5.0-5.75 | | 4.25-7.75 | 12-13.75 | | |||

7.5-8 | | 9.5-25 | 15.5-40 |

|

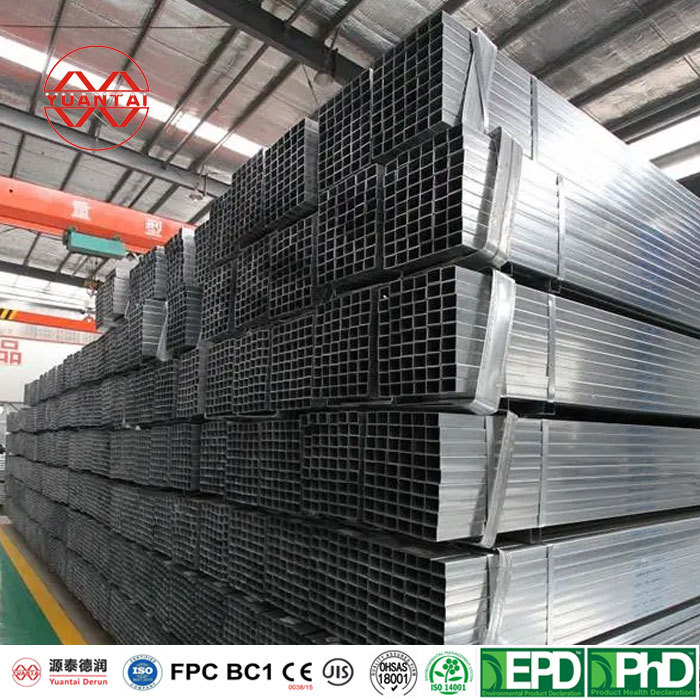

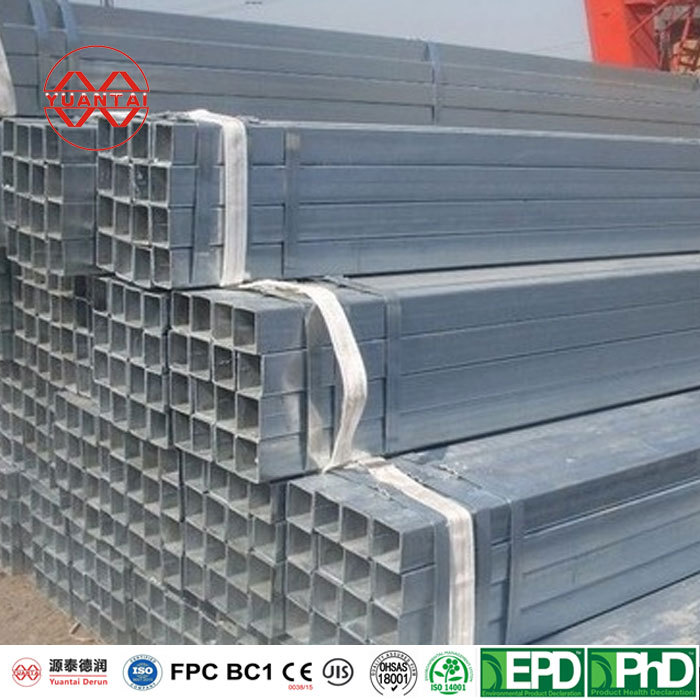

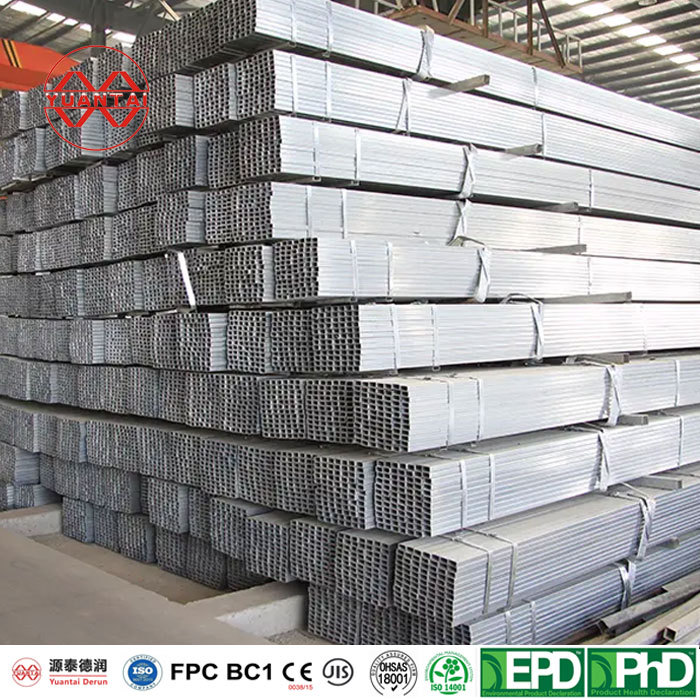

8 factories, 103 production lines, 80 patented technologies, China's top 500 private enterprises and China's top 500 manufacturing industries, with an annual output of 10 million tons and a perennial spot supply of 200000 tons. China's largest square tube manufacturer.

Yuantai Derun's main products include square steel pipe, rectangular steel pipe, hot-dip galvanized steel pipe, ERW steel pipe, LSAW steel pipe, spiral steel pipe, seamless steel pipe, stainless steel pipe, galvanized coil, ppgi coil,ZAM coil and stainless steel coils.

Strength and durability:

Versatility:

Easy fabrication and installation:

Cost-effective

Excellent structural support:

Aesthetic appeal:

- 1. 100% after-sales quality and quantity assurance.

- 2. Professional sales manager quickly reply within 24 hours.

- 3. Large Stock for regular sizes.

- 4. Free sample 20cm high quality.

- 5. Strong produce capability and capital flow.

- 6. Small order accepted.

- 7. Brand name raw material

- 8. Support OEM or ODM

- 9. 21 years Manufacturing experience

- 10. It can manufacture steel pipes of different projects and standards in the world

- 11.Yuantai Derun has a standing stock of more than 200000 tons, and the annual shipment specification is: 20*20*1.0—1000*1000*50mm,20*30*1.0—800*1200*50mm,Φ 219— Φ 3620mm,The black, hot-dip galvanized rectangular pipe and spiral welded pipe made of S235-S460 have an existing capacity of nearly 5 million tons,

- 12.After the completion of the new base in Tangshan, the total production capacity will reach 10 million tons.

- Loading...

- Name

- Tel

- *Title

- *Content

- square steel pipe

- rectangular steel pipe

- round steel pipe

- shaped tube

- LSAW steel pipe

- zinc aluminium magnesium coating steel pipe

- galvanized steel pipe

- ERW steel pipe

- seamless steel pipe

- spiral steel pipe

- LINE PIPE&OCTG

- stainless steel pipe

- steel coil

- steel plate

- ship building steel pipe

- photovoltaic bracket

- steel profile

- Name

- Tel

- *Title

- *Content