Home / All / zinc aluminium magnesium coating steel pipe /

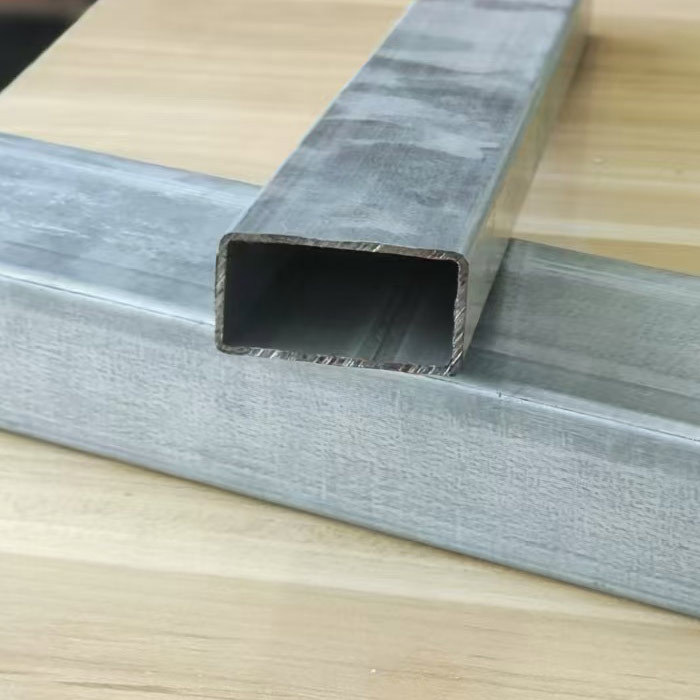

Zinc Aluminum Magnesium Coated Rectangular Steel Tubes

Zinc Aluminum Magnesium Coated Rectangular Steel Tubes

Detail Information

Zinc Aluminum Magnesium Coated Rectangular Steel Tubes

Zinc aluminum magnesium coated rectangular steel tube is a new type of anti-corrosion steel pipe independently developed by Yuantai Derun. The surface coating is covered with an alloy coating composed of zinc aluminum magnesium alloy, which can effectively isolate external corrosion and greatly extend the service life of the rectangular steel tube Compared with ordinary pre galvanized rectangular steel tubes, zinc aluminum magnesium rectangular steel tubes have stronger anti-corrosion performance and can better cope with harsh environments such as humidity, salt spray, acidity, and alkalinity. Send Your Inquiry Now!

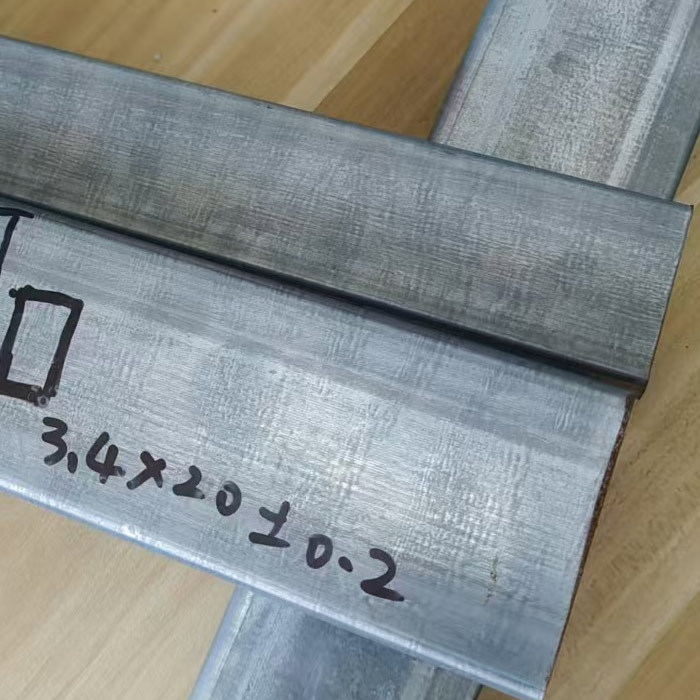

Zinc Aluminum Magnesium Coated Rectangular Tube Sizes

At present, the dimensions of the zinc aluminum magnesium coated rectangular tubes produced by Yuantai Derun are shown in the table below. The diameter, wall thickness, and length can be customized and produced within the range shown in this table. The factory price for ordering is very affordable.

|

Grade

|

Outer Diameter(mm)

|

Wall Thickness(mm)

|

Length(M)

|

Coating Composition | Zinc Content On Coating | Coating Weight(g/m²) | Coating Form | Inspection Method |

|

S250GD+ZM

S350GD+ZM S420GD+ZM S450GD+ZM |

10*10-200*200

|

0.5-2.75

|

0.5-24M

|

zinc aluminum magnesium alloy | high zinc or standard | 40-275 | Equal thickness coating | Yield testing, tensile testing, salt spray testing, impact testing, size, shape, surface quality testing |

ZAM Coated Rectangular Tube Advantage

Tight Weld Seam

Smooth And Beautiful Surface

Uniform Thickness

High Strength

High Dimensional Accuracy

Good Mechanical Performance

ZAM Coated Rectangular Steel Tube Manufacturing Process

The manufacturing process of zinc aluminum magnesium coated rectangular steel pipes mainly includes the following steps:

1. Uncoiling of zinc aluminum magnesium steel coil

2. Edge cutting and butt welding

3. Straightening

4. Loop storage

5. Roll cold forming

6. High frequency welding

7. Removing excess welding bars

8. Water cooling

9. Cutting

10. Detecting and picking out unqualified joint pipes

11. Spray marking and packaging

Application

In the construction industry, zinc aluminum magnesium coated rectangular steel tubes are commonly used for building structures, roofs, and wall coverings. It has the characteristics of high strength, corrosion resistance, good seismic resistance, and easy construction, which can improve the stability and safety of buildings.

In the automotive industry, zinc aluminum magnesium coating rectangular tubes can be used for the manufacturing of car bodies and chassis. It has high strength and corrosion resistance, which can improve the overall quality and durability of the car.

In the aerospace field, zinc aluminum magnesium rectangular steel tubes can be used for aircraft, rockets, etc. The high strength of zinc aluminum magnesium steel pipes is due to the addition of magnesium elements, which gives them higher toughness and strength. This makes zinc aluminum magnesium steel pipes have excellent performance in carrying weight and resisting external environmental influences.

In the fields of electrical appliances and light industry, zinc aluminum magnesium steel tubes are commonly used to manufacture electrical equipment, household appliances, and lighting equipment. Zinc aluminum magnesium steel pipes also have high temperature resistance. This material can usually operate in high temperature environments around 200 ℃ without severe damage.

In addition, zinc aluminum magnesium coating rectangular steel tubes are also a very easy to process material. Due to its smooth surface and ease of cutting and processing, it can meet various needs. Therefore, this material has been widely used in machining, DIY, and other industries.

Review

- Loading...

Please send your message to us

Yuantai team has over 21 years of experience in steel pipe project applications, specializing in the production, manufacturing, and customization of square rectangular, and circular steel pipes. Warmly welcome project procurement managers, individual owners, designers, and overall sellers, etc. Write down your requirements and receive professional quotes and technical support.

- Name

- Tel

- *Title

- *Content

Categories

- square steel pipe

- rectangular steel pipe

- round steel pipe

- shaped tube

- LSAW steel pipe

- zinc aluminium magnesium coating steel pipe

- galvanized steel pipe

- ERW steel pipe

- seamless steel pipe

- spiral steel pipe

- LINE PIPE&OCTG

- stainless steel pipe

- steel coil

- steel plate

- ship building steel pipe

- photovoltaic bracket

- steel profile

subscription

Please send your message to us

Yuantai team has over 21 years of experience in steel pipe project applications, specializing in the production, manufacturing, and customization of square rectangular, and circular steel pipes. Warmly welcome project procurement managers, individual owners, designers, and overall sellers, etc. Write down your requirements and receive professional quotes and technical support.

- Name

- Tel

- *Title

- *Content