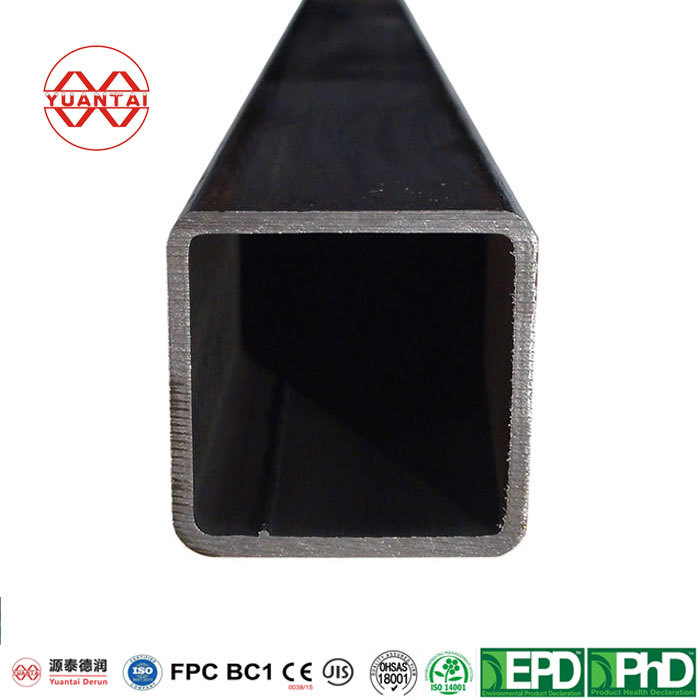

Yuantai Hot Rolled/Finished EN10210 Steel Hollow Section

Yuantai Hot Rolled/Finished EN10210 Steel Hollow Section

2.The Forming Process Of EN10210 Hot Rolled/Finished Hollow Section

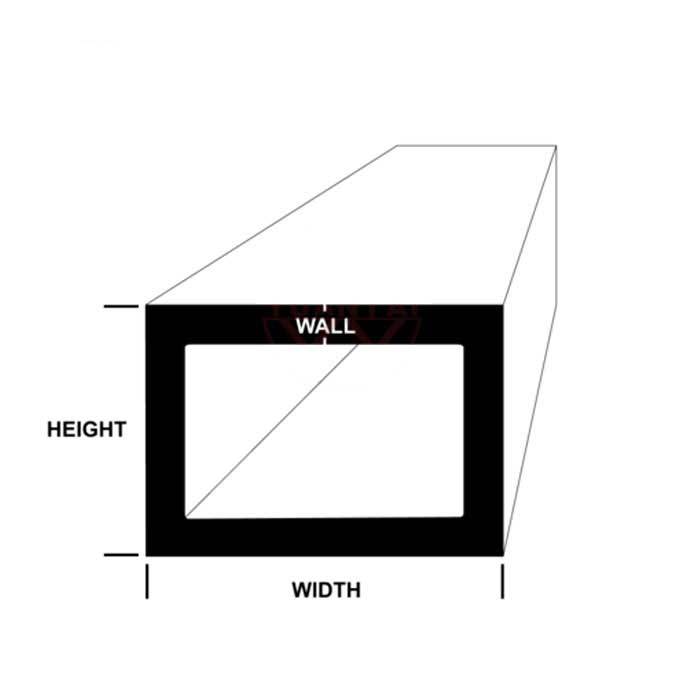

3.EN10210 Hot Rolled/Finished Steel Hollow Sections Sizes

|

O.D. mm |

W.T.mm |

O.D mm |

W.T. mm |

O.D mm |

W.T. mm |

O.D mm |

W.T. mm |

|

20*20 |

1.3 |

60*120 80*100 90*90 |

1.50 |

180*180 |

3 |

300*800 400*700 550*550 500*600 |

|

|

1.4 |

1.70 |

3.5-3.75 |

9.5-9.75 |

||||

|

1.5 |

1.80 |

4.5-4.75 |

11.5-11.75 |

||||

|

1.7 |

2.00 |

5.5-7.75 |

12-13.75 |

||||

|

1.8 |

2.20 |

9.5-9.75 |

15-50 |

||||

|

2.0 |

2.5-4.0 |

11.5-11.75 |

|

||||

|

20*30 25*25 |

1.3 |

4.25-4.75 |

12.0-25.0 |

|

|||

|

1.4 |

5.0-6.3 |

100*300 150*250 200*200 |

2.75 |

300*900 400*800 600*600 500*700 |

|

||

|

1.5 |

7.5-8 |

3.0-4.0 |

9.5-9.75 |

||||

|

1.7 |

50*150 60*140 80*120 100*100 |

1.50 |

4.5-9.75 |

11.5-11.75 |

|||

|

1.8 |

1.70 |

11.5-11.75 |

12-13.75 |

||||

|

2.0 |

2.00 |

12.5-12.75 |

15-50 |

||||

|

2.2 |

2.20 |

13.5-13.75 |

|

||||

|

2.5-3.0 |

2.5-2.75 |

15.5-30 |

|

||||

|

20*40 25*40 30*30 30*40 |

1.3 |

3.0-4.75 |

150*300 200*250 |

3.75 |

300*1000 400*900 500*800 600*700 650*650 |

|

|

|

1.4 |

5.5-6.3 |

4.5-4.75 |

|

||||

|

1.5 |

7.5-7.75 |

5.5-6.3 |

9.5-9.75 |

||||

|

1.7 |

9.5-9.75 |

7.5-7.75 |

11.5-11.75 |

||||

|

1.8 |

11.5-16 |

9.5-9.75 |

12-13.75 |

||||

|

2.0 |

60*160 80*140 100*120 |

2.50 |

11.5-11.75 |

15-50 |

|||

|

2.2 |

2.75 |

13.5-30 |

|

||||

|

2.5-3.0 |

3.0-4.75 |

200*300 250*250 |

3.75 |

400*1000 500*900 600*800 700*700 |

|

||

|

3.25-4.0 |

5.5-6.3 |

4.5-4.75 |

|

||||

|

25*50 30*50 30*60 40*40 40*50 40*60 50*50 |

1.3 |

7.5-7.75 |

5.5-6.3 |

9.5-9.75 |

|||

|

1.4 |

9.5-16 |

7.5-7.75 |

11.5-11.75 |

||||

|

1.5 |

75*150 |

2.50 |

9.5-9.75 |

12-13.75 |

|||

|

1.7 |

2.75 |

11.5-11.75 |

15-50 |

||||

|

1.8 |

3.0-3.75 |

12-13.75 |

|

||||

|

2.0 |

4.5-4.75 |

15.5-30 |

|

||||

|

2.2 |

5.5-6.3 |

200*400 250*350 300*300 |

4.5-6.3 |

500*1000 600*900 700*800 750*750 |

|

||

|

2.5-3.0 |

7.5-7.75 |

7.5-7.75 |

9.5-9.75 |

||||

|

3.25-4.0 |

9.5-16 |

9.5-9.75 |

11.5-11.75 |

||||

|

4.25-4.75 |

80*160 120*120 |

2.50 |

11.5-11.75 |

12-13.75 |

|||

|

5.0-5.75 |

2.75 |

12-13.75 |

15-50 |

||||

|

5.75-6.3 |

3.0-4.75 |

15.5-30 |

|

||||

|

40*80 50*70 50*80 60*60 |

1.3 |

5.5-6.3 |

200*500 250*450 300*400 350*350 |

5.5-6.3 |

500*1100 600*900 700*800 800*800 |

|

|

|

1.5 |

7.5-7.75 |

7.5-7.75 |

9.5-9.75 |

||||

|

1.7 |

9.5-9.75 |

9.5-9.75 |

11.5-11.75 |

||||

|

1.8 |

11.5-20 |

11.5-11.75 |

12-13.75 |

||||

|

2.0 |

100*150 |

2.50 |

12-13.75 |

15-50 |

|||

|

2.2 |

2.75 |

15.5-30 |

|

||||

|

2.5-3.0 |

3.0-4.75 |

280*280 |

5.5-6.3 |

600*1100 700*1000 800*900 850*850 |

|

||

|

3.25-4.0 |

5.5-6.3 |

7.5-7.75 |

9.5-9.75 |

||||

|

4.25-4.75 |

7.5-7.75 |

9.5-9.75 |

11.5-11.75 |

||||

|

5.0-6.0 |

9.5-9.75 |

11.5-11.75 |

12-13.75 |

||||

|

40*100 60*80 70*70 |

1.3 |

11.5-20 |

12-13.75 |

15-50 |

|||

|

1.5 |

100*200 120*180 150*150 |

2.50 |

15.5-30 |

|

|||

|

1.7 |

2.75 |

350*400 300*450 |

7.5-7.75 |

700*1100 800*1000 900*900 |

|

||

|

1.8 |

3.0-7.75 |

9.5-9.75 |

11.5-11.75 |

||||

|

2.0 |

9.5-9.75 |

11.5-11.75 |

12-13.75 |

||||

|

2.2 |

11.5-20 |

12-13.75 |

15-50 |

||||

|

2.5-3.0 |

100*250 150*200 |

3.00 |

15.5-30 |

|

|||

|

3.25-4.0 |

3.25-3.75 |

200*600 300*500 400*400 |

7.5-7.75 |

800*1100 900*1000 950*950 |

|

||

|

4.25-4.75 |

4.25-4.75 |

9.5-9.75 |

11.5-11.75 |

||||

|

5.0-6.3 |

9.5-9.75 |

11.5-11.75 |

12-13.75 |

||||

|

50*100 60*90 60*100 75*75 80*80 |

1.3 |

11.5-11.75 |

12-13.75 |

15-50 |

|||

|

1.5 |

12.25 |

15.5-40 |

|

||||

|

1.7 |

140*140 |

3.0-3.75 |

300*600 400*500 450*450 |

7.5-7.75 |

900*1100 1000*1000 800*1200 |

|

|

|

1.8 |

4.5-6.3 |

9.5-9.75 |

|

||||

|

2.0 |

7.5-7.75 |

11.5-11.75 |

20-60 |

||||

|

2.2 |

9.5-9.75 |

12-13.75 |

|

||||

|

2.5-3.0 |

11.5-25 |

15.5-40 |

|

||||

|

3.25-4.0 |

160*160 |

3.00 |

400*600 500*500 |

9.5-9.75 |

1100*1000 1200*1200 |

|

|

|

4.25-4.75 |

|

3.5-3.75 |

11.5-11.75 |

20-60 |

|||

|

5.0-5.75 |

|

4.25-7.75 |

12-13.75 |

|

|||

|

7.5-8 |

|

9.5-25 |

15.5-40 |

|

4.Hot Rolled/Finished EN10210 Steel Hollow Section Material

5.Mechanical Properties Of Hot Rolled/Finished Steel Hollow Sections:

|

Steel Grade

|

Yield Strenth(MPa)

|

Tensile strength(MPa)

|

Elongation(%)

|

Impact | Carbon equivalent

(CEV) max | ||

T ≤ 16mm | T > 16mm | 3mm < T ≤ 100mm | T | ℃ | J | ||

|

S460NH

|

460

|

540-720

|

17

|

-40 | 27 | 0.45 | |

|

Steel Grade

|

Yield Strenth(MPa)

|

Tensile strength(MPa)

|

Elongation(%)

|

Impact | Carbon equivalent

(CEV) max | ||

T ≤ 16mm | T > 16mm | T ≤ 65mm | T | ℃ | J | ||

|

S420NH

|

460

|

520-680

|

19

|

-20 | 40 | 0.45 | |

|

Steel Grade

|

Yield Strenth(MPa)

|

Tensile strength(MPa)

|

Elongation(%)

|

Impact | Carbon equivalent

(CEV) max | ||

T ≤ 16mm | T > 16mm | 3mm<T ≤ 100mm | T | ℃ | J | ||

|

S355NH

|

355

|

345 |

470-630

|

22

|

-20 | 40 | 0.43 |

6. Chemical Composition

Steel Grade |

C max(%)

|

Si max

(%) |

Mn (%) | P max (%) | S max (%) |

Nb max

(%) |

V max (%) | Al total min(%) | Ti max (%) | Cr max (%) | Ni max (%) |

Mo max

(%) |

Cu max (%) | N max (%) |

S460NH |

0.22

|

0.60

|

1.70 | 0.035 | 0.030 |

0.050

|

0.20 | 0.020 | 0.03 | 0.30 | 0.80 |

0.10

|

0.70 | 0.025 |

S420NH |

0.20

|

0.60

|

1.00- 1.70 | 0.035 | 0.030 |

0.050

|

0.20 | 0.020 | 0.03 | 0.30 | 0.80 |

0.10

|

0.70 | 0.025 |

S355NH |

0.20

|

0.50

|

0.90- 1.65 | 0.035 | 0.030 |

0.050

|

0.12 | 0.020 | 0.03 | 0.30 | 0.50 |

0.10

|

0.35 | 0.020 |

7.Specification And Physical Parameters Of EN10210 European Standard Steel Hollow Section

Size(mm) | THK(mm) | Weight(kg/m) | Sectional area(CM2) | Moment of inertia Ix(CM4) |

Moment of inertia Iy(CM4)

|

Torsional moment of inertia J(CM4)

|

Section modulus Wx(CM3)

|

Section modulus Wy(CM3)

|

40×40 | 1.85 | 2.30 | 3.07 | 0.46 |

0.46

|

0.021

|

0.60

|

0.60

|

50×50 | 2.35 | 2.93 | 4.04 | 1.02 |

1.02

|

0.051

|

1.33

|

1.33

|

60×60 | 2.35 | 3.54 | 4.89 | 1.53 |

1.53

|

0.092

|

2.22

|

2.22

|

70×70 | 2.5 | 4.25 | 5.85 | 2.34 | 2.34 | 0.159 | 3.43 | 3.43 |

80×80 | 2.5 | 4.92 | 6.77 | 3.05 | 3.05 | 0.251 | 4.83 | 4.83 |

90×90 | 3 | 6.36 | 8.75 | 4.43 | 4.43 | 0.468 | 7.22 | 7.22 |

100×100 | 3 | 7.11 | 9.74 | 5.43 | 5.43 | 0.691 | 9.03 | 9.03 |

8. Tolerances

|

|

||

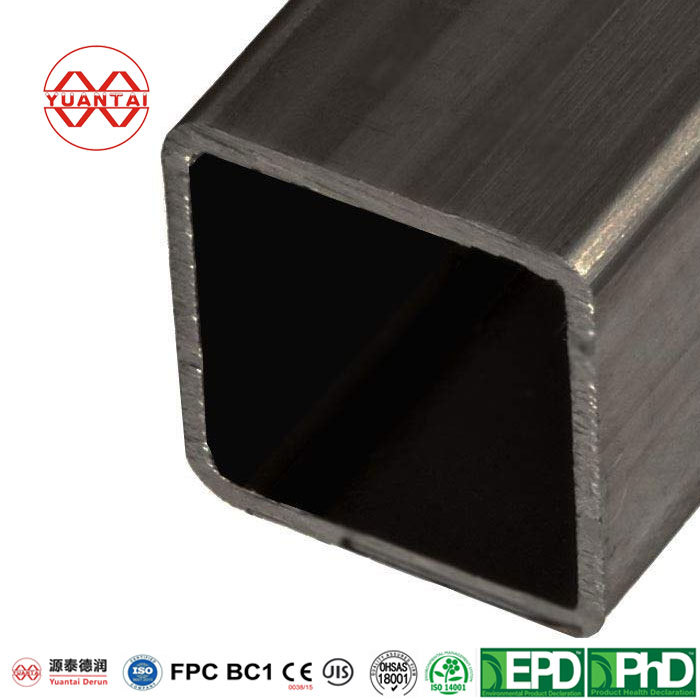

9.Advantage Of EN10210 Hot Rolled/Finished Steel Hollow Section

Pipe orifice leveling

The surface shall be painted to prevent oxidation

Uniform thickness

High yield

The inner wall of the pipe shall be flat and smooth without burrs

Safe transportation in its own fleet

10. Free Samples For You

11. Application Of EN10210 Hot Rolled / Finished Steel Hollow Section

Packaging And Shipping

Why Choose Yuantai Derun?

- 1. 100% after-sales quality and quantity assurance.

- 2. Professional sales manager quickly reply within 24 hours.

- 3. Large Stock for regular sizes.

- 4. Free sample 20cm high quality.

- 5. Strong produce capability and capital flow.

- 6. Small order accepted.

- 7. Brand name raw material

- 8. Support OEM or ODM

- 9. 21 years Manufacturing experience

- 10. It can manufacture steel pipes of different projects and standards in the world

- 11. Yuantai has a standing stock of more than 200000 tons, and the annual shipment specification is:

- 10*10*1.0—1200*1200*60mm,

- 10*15*0.5—800*1200*60mm,

- Φ 219— Φ 3620mm,

- The black steel pipe, hot-dip galvanized rectangular pipe and spiral welded pipe have an existing capacity of nearly 5 million tons,

- After the completion of the new base in Tangshan, the total production capacity will reach 10 million tons.

- Loading...

- Name

- Tel

- *Title

- *Content

- square steel pipe

- rectangular steel pipe

- round steel pipe

- shaped tube

- LSAW steel pipe

- zinc aluminium magnesium coating steel pipe

- galvanized steel pipe

- ERW steel pipe

- seamless steel pipe

- spiral steel pipe

- LINE PIPE&OCTG

- stainless steel pipe

- steel coil

- steel plate

- ship building steel pipe

- photovoltaic bracket

- steel profile

- Name

- Tel

- *Title

- *Content