Spiral steel pipe specification model weight table Introduction to the implementation standard of spiral steel pipe

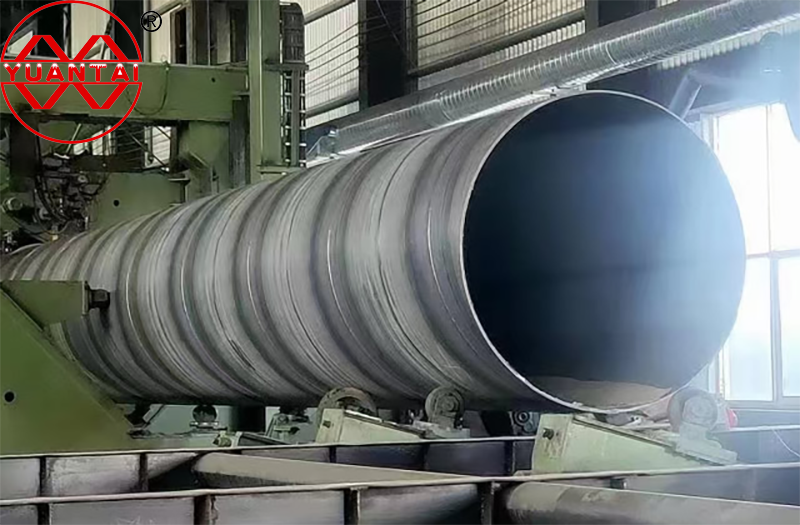

spiral welded steel pipe

Spiral steel pipe specification model weight table

As an important building material, spiral steel pipe is widely used in construction, chemical, petroleum, natural gas and other industries. When choosing spiral steel pipe, specification model and weight are very important reference factors. The following is a commonly used spiral steel pipe specification model weight table for reference:

Specification model|diameter (mm)|wall thickness (mm)|length (m))|theoretical weight (kg/m)

Spiral steel pipe S1080|1020|816-12|145.21

Spiral steel pipe S1200|1200|8|6-12|189.7

Spiral steel pipe S1400|1400|816-12|233.9

Spiral steel pipe S1600|1600|8|6-121278.21

As can be seen from the above table, the weight of spiral steel pipes of different specifications is also different. In actual purchase and use, you can choose the appropriate pipe according to actual needs and theoretical weight.

Introduction to the Execution Standards for Spiral Steel Pipes

In the field of spiral steel pipes, common implementation standards include GB/T 9711, GB/T 3091, SY/T 5037, etc. Among them, GBIT 9711 is the standard for steel pipes used in the transportation of petroleum and natural gas industries, applicable to steel pipes used for transporting fluids such as petroleum and natural gas; GBIT 3091 is a welding steel pipe standard for low-pressure fluid transportation, suitable for steel pipes transporting low-pressure fluids such as water, gas, and air. SYIT 5037 is a welding steel pipe standard for the petroleum and natural gas industry, suitable for welding steel pipes transporting fluids such as oil and gas

3、 Production process and quality control of spiral steel pipe

1. Raw material procurement

(1) Selected high-quality steel billets: Select high-quality steel billets that meet national standards to fundamentally ensure the quality of spiral steel pipes.

(2) Strict inspection: Conduct strict quality inspection on the incoming steel billets, including size, appearance, chemical composition, etc., to ensure that they meet production requirements.

2. Production process

(1) Heating: Heat the steel billet to a predetermined temperature to ensure the plasticity and toughness of the steel.

(2) Rolling: Advanced rolling equipment is used to gradually form spiral steel pipes from steel billets through multiple passes of rolling,

(3) Molding: Adopting professional molding technology to ensure the shape and dimensional accuracy of spiral steel pipes.

(4) Welding: Advanced welding technology is used to ensure the quality of the weld seam of the spiral steel pipe,

3. Finished product testing

(1) Appearance inspection: Conduct appearance inspection on finished spiral steel pipes, including surface flatness, weld quality, etc.

(2) Dimensional inspection: Accurately measure the dimensions of finished spiral steel pipes to ensure compliance with national or industry standards.

(3) Strength testing: Conduct strength testing on finished spiral steel pipes to ensure they have good compressive strength and durability.

(4) Anti corrosion testing: Conduct anti-corrosion testing on finished spiral steel pipes to ensure they have a long service life.