Do you know the factors that affect the outer diameter accuracy of thick walled rectangular tubes?

Do you know the factors that affect the outer diameter accuracy of thick walled rectangular tubes?

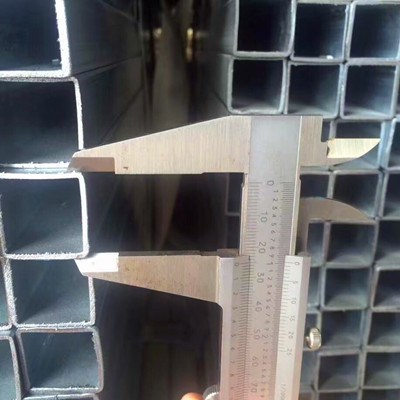

The outer diameter accuracy of thick walled square rectangular pipe is determined by human, and the result depends on the customer. It depends on the customer's requirements for the outer diameter of seamless pipe, the operation and accuracy of steel pipe sizing equipment, and the steel pipe sizing process system.

The sizing method of seamless pipe is an important factor to determine the outer diameter tolerance of steel pipe. The outer diameter accuracy of thick walled square pipes with longitudinal rolling sizing can reach about 1%, while the outer diameter accuracy of seamless pipes with cross rolling sizing can reach 0.5%.

The influence of the technological system on the accuracy of the outer diameter of the steel pipe mainly depends on the rolling temperature and temperature stability of the steel pipe sizing machine. The rolling temperature of steel pipe is high, and the shrinkage of thick wall square pipe after rolling is large, which is often easy to exceed the outer diameter to produce negative deviation of steel pipe; On the contrary, the low rolling temperature may exceed the positive deviation and become a defective product. Therefore, the steel pipe rolling mill shall be continuously adjusted according to the size specification, steel pipe grade, temperature condition and tool wear condition of the sizing thick wall square pipe.

In the process of rapid industrial development, the proportion of thick walled square tubes in China's steel output is increasing. Due to the wide use of thick wall square pipe, higher requirements are put forward for its quality. Among them, the wall thickness deviation of thick walled square tubes is one of the important indicators of their quality, because the wall thickness deviation will directly affect the use range of thick walled square tubes. In the current increasingly fierce market competition, if a thick walled square tube manufacturer cannot work hard on quality and cannot produce high-quality thick walled square tubes, it is inevitable that many market shares will be lost.

Through decades of continuous efforts and practice, as well as a large number of technical exchanges and practical operation changes with some powerful manufacturers, many thick walled square tube manufacturers have significantly improved the wall thickness deviation of thick walled square tubes.

Let's talk about some problems of thick wall square tubes in the actual production process: the deviation produced in the piercing process of the piercer, the equipment manufacturing accuracy and structure, the installation and adjustment of the equipment line, the heating process of the tube blank, the blanking of the tube blank, the influence of the tool accuracy, and the use of the automatic tube rolling machine.