How to straighten galvanized square pipe?

How to straighten galvanized square pipe?

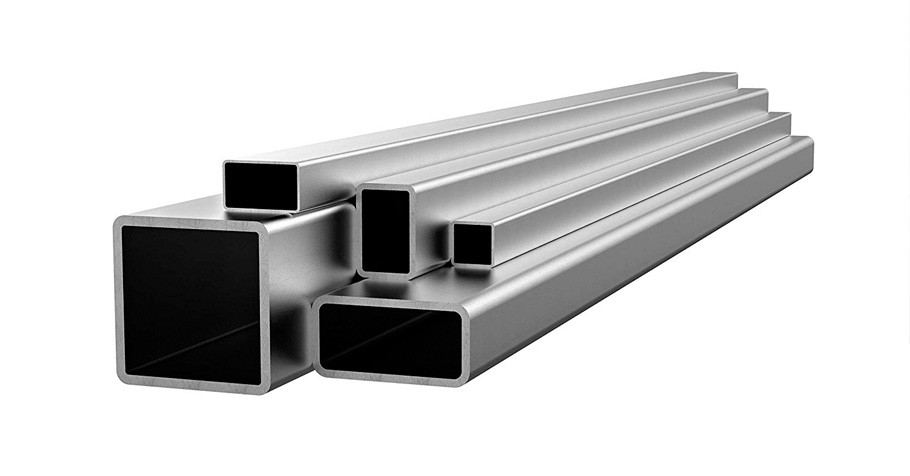

Galvanized square pipe has good performance, and the demand for galvanized square pipe is very large, so how to straighten the galvanized square pipe? Next, let's explain it in detail.

Zigzag of galvanized square pipe is caused by improper adjustment of rolling mill, residual stress during rolling and uneven cooling along the pipe section and length. Therefore, it is impossible to obtain very straight tubes directly from the rolling mill. Only by cold straightening the bending degree of the pipe can the requirements of the technical conditions be met.

The basic principle of straightening is to make the galvanized square pipe undergo elastic-plastic torsion, from large torsion to small torsion. Therefore, the steel pipe must be repeatedly twisted in the straightener. The degree of repeated torsion of steel pipe mainly depends on the adjustment of straightener.

There are many factors affecting the straightening quality, such as the bending degree of the original pipe, the size of the steel pipe, the straightening method of the material, and the adjustment parameters.

Many galvanized square pipe suppliers will provide chemical compatibility tables. However, the engineer should note that the chemical compatibility table specially prepared for galvanized square pipes should be used instead of the chemical compatibility table prepared for ordinary pipes.

Therefore, reference can only be made to galvanized square pipes, not to the chemical compatibility level between ordinary pipes and related substances. Otherwise, galvanized square pipes will fail or be damaged, cracked and leaked, resulting in pump damage or risk accidents.