Essential difference between welded square pipe and seamless square pipe

Essential difference between welded square pipe and seamless square pipe

The production process of square tubes is simple, the production efficiency is high, the varieties and specifications are various, and the materials are different. Next, we will explain the essential differences between welded square tubes and seamless square tubes in detail.

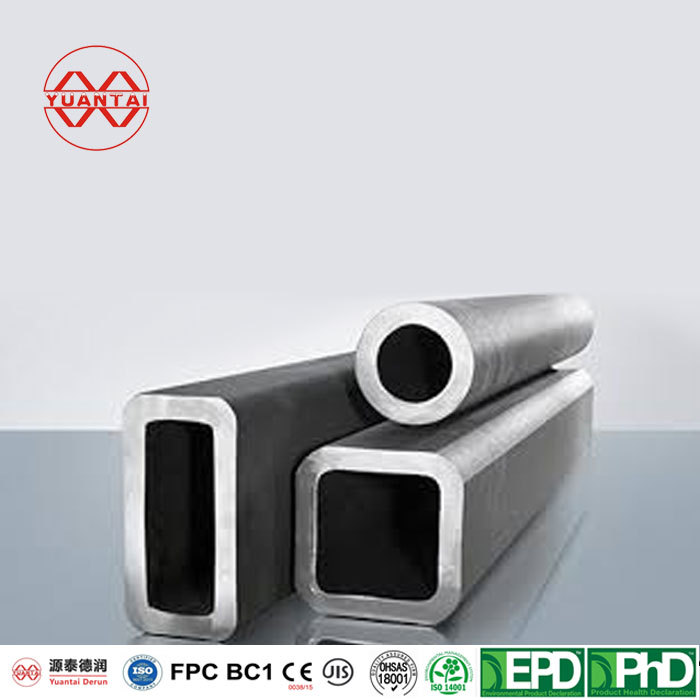

1. Welded square pipe is a hollow square steel square pipe, also known as hollow cold-formed steel. Section steel of square section shape and size.

In addition to thickening the wall thickness of thick walled square pipe, its edge size and edge straightness have reached or even exceeded the level of resistance welding cold bending square pipe. The size of R angle is generally 2 - 3 times of the wall thickness, and the R angle square tube can also be produced according to the needs of customers.

2. Seamless square pipe is a kind of hollow section long steel with no joints around. It is a square tube formed by extruding seamless tubes through the four sides of the die. The square tube has a hollow section and is used to transport a large amount of fluid. It is mainly used in liquid transportation, hydraulic support, mechanical structure, medium and low pressure, high pressure boiler tubes, heat exchange tubes, gas, oil and other industries. It is stronger than welded and will not crack.

In Yuantai's workshop, whether it is welded square pipe or seamless steel pipe, we can mass customize the production.