Circular pipe welding is a common connection process widely used in various industries. When welding circular pipes, we need to choose a suitable welding method to ensure welding quality and efficiency. The common welding methods and characteristics of circular pipes are as follows.

1. Arc welding

Arc welding is the use of an electric arc to generate high temperatures and weld workpieces together. Arc welding is suitable for circular pipes of various materials, with fast welding speed and wide applicability, but requires high operational skills.

2. Gas shielded welding

Gas shielded welding is a welding method that uses inert gas or active gas to protect the welding area. Common gas shielded welding methods include argon arc welding and argon shielded welding. Gas shielded welding can effectively prevent oxidation and hydrogen cracking, with high welding quality, suitable for circular pipes with high welding quality requirements.

3. Welding joint form

When welding circular pipes, common joint forms include butt welding, lap welding, and fillet welding.

Butt welding is the process of aligning the ends of two circular pipes for welding, resulting in high-quality welding;

Overlap welding is the process of welding the ends of two circular pipes at a certain distance apart, which is suitable for situations where the strength requirements for the joint are not high;

Corner welding is the process of welding the ends of two circular tubes at a certain angle, suitable for connecting circular tubes in different directions.

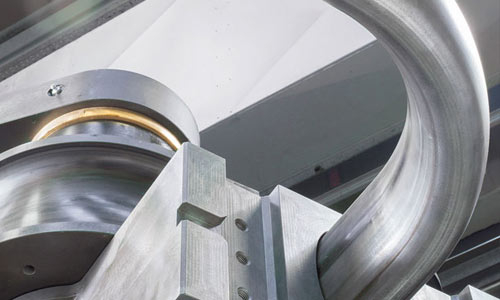

4. Selection of welding equipment

When selecting the welding method for circular pipes, it is also necessary to choose suitable welding equipment according to the actual situation.

Common welding equipment includes manual arc welding machines, gas shielded welding machines, submerged arc welding machines, etc.

Different welding equipment is suitable for different circular pipe welding methods, and selecting the appropriate welding equipment can improve welding efficiency and quality.

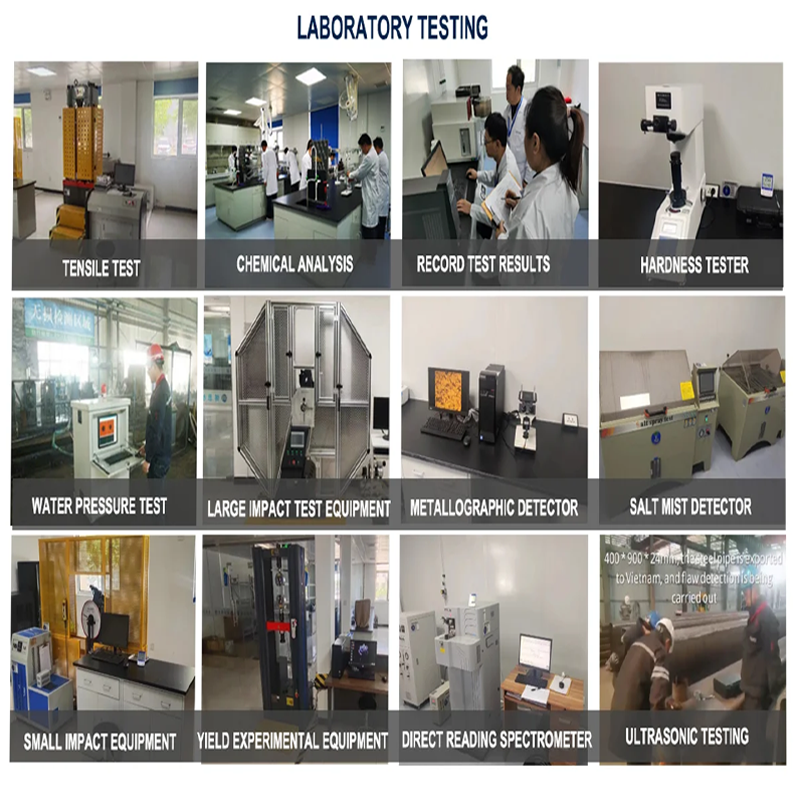

5. Welding process control

When welding circular pipes, it is necessary to strictly control the welding process, including parameters such as welding current, welding speed, and welding temperature. Reasonable welding process control can ensure welding quality, avoid the occurrence of welding defects, and improve welding efficiency.