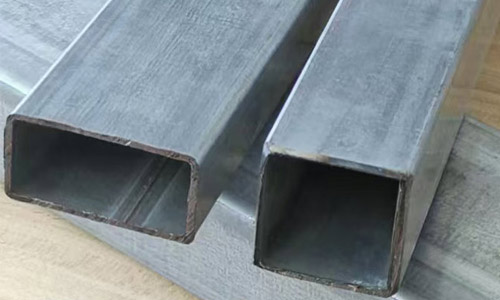

Rectangular Tubing & Pipe

Dimensions:10*15-800*1200mm or custmized

W.T.: 0.5-60mm or custmized

Length:0.5-26.5m or custmized

Grade:Gr.A/B/C,S235/275/355/420/460,A36,SS400,Q195/235/355,STKR400/490,300W/350W,etc.

Standard:

ASTM A500/A501,EN10219/10210,JIS G3466,GB/T6728/3094 AS1163, CSA G40.20/G40.21,etc.

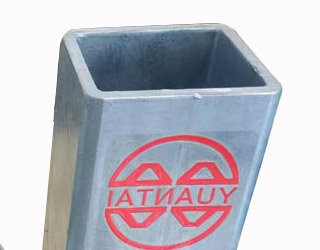

Surface Treatment:Bare,oil,painted,galvanized,etc.

MOQ: 2-5 Tons

Capacity: 5 million tons / year

Packaging: PVC package or follow your needs

Port of origin: Tianjin Port

Payment:TT/LC,etc