1. Cutting method: This method uses a fixed blade or rotating cutting head inserted into the tube to cut burrs.

2. Rolling method: This method uses a rolling device inserted into the pipe to cause plastic deformation of the internal burrs, achieving the effect of thinning the height of the internal burrs.

3. Oxidation method: At the beginning of steel pipe welding, an oxygen flow is sprayed into the inner weld seam through a ventilation nozzle, and the residual heat of the weld seam is used to accelerate the oxidation of internal burrs, which fall off under the airflow.

4. Pulling method: When the steel pipe passes through the mold, the burrs inside the steel pipe are removed under the action of the circular blade of the floating plug.

There are 5 measures to eliminate welding stress:

1. It is best not to pull weld during welding

That is, do not weld the joints at one time, spot weld and weld in sections to release the stress continuously.

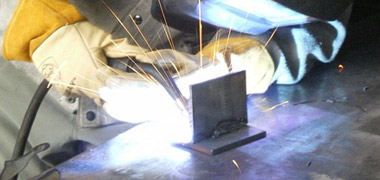

2. Use hammering weld method

During the section welding process, the weld should be hit with a hammer continuously, and the residual stress should be controlled by vibration to eliminate the generated stress.

When the weld metal cools, stress is generated due to the shrinkage of the weld. By hammering the weld area, the stress can be reduced by 1/2~1/4. The temperature should be maintained between 100-150℃ or above 400℃ during hammering, and avoid 200-300℃, because the metal is in the blue brittle stage at this time, and the hammered weld is easy to break. When multi-layer welding, each layer should be hammered except the first and last layer of welds. The first layer is not hammered to avoid root cracks, and the last layer is to prevent cold work hardening caused by hammering.

Vibration aging can eliminate 30%-50% of stress, which is an effective method to reduce welding stress.

3. Release welding stress

If the weldment allows, several small round holes can be made in a row on the weldment to release welding stress.

4. Outflow stress release gap

When welding the sealing parts, the stress release at one end should be ensured, that is, a gap for stress release should be left, and the weldment should be fully welded after it is completely cooled naturally (the gap should be left for the first section to be welded)

5. Use reasonable welding sequence and direction

First weld the weld with larger shrinkage, so that the weld can shrink more freely to minimize welding stress.

First weld the staggered short welds, and then weld the straight long welds.

First weld the welds that are subjected to greater stress during work, so that the internal stress is reasonably distributed.