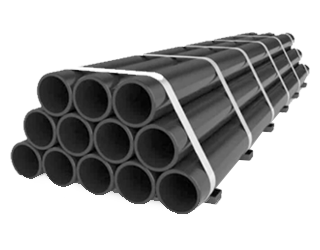

Seamless steel pipe: smooth surface, no welds, good integrity, beautiful appearance.

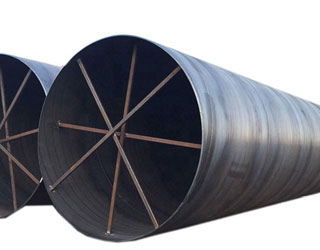

Welded pipe: Since it is made by welding, the weld can be clearly seen on its surface. However, with the advancement of technology, some welded steel pipes will be welded to make the weld less obvious.

Performance characteristics

Seamless steel pipe: Since there is no weld, its pressure bearing capacity is usually high, suitable for harsh environments such as high pressure and high temperature. At the same time, the precision and finish of seamless steel pipes are relatively high, suitable for occasions with high requirements for steel pipe performance.

Welded pipe: Although the pressure bearing capacity is lower than that of seamless steel pipes, the cost is low and it is easy to process and install.

Seamless steel pipe: Due to the complex manufacturing process and superior performance, its price is usually higher than that of welded steel pipe. However, the specific price will also be affected by factors such as market supply and demand, raw material price fluctuations, etc.

Welded pipe: Low cost, suitable for large-scale, low-cost application scenarios.

Uses

Seamless steel pipe

Seamless steel pipe is mainly used for petroleum geological drilling pipe, petrochemical cracking pipe, boiler pipe, bearing pipe and high-precision structural steel pipe for automobile, tractor and aviation. In addition, it is also widely used in the fields of petroleum, chemical, electric power, nuclear energy, etc., especially in the occasions where it needs to withstand harsh environments such as high pressure, high temperature and corrosion.

Seamless steel pipe is also commonly used to manufacture structural parts and mechanical parts, such as oil drill pipe, automobile transmission shaft, bicycle frame and steel scaffolding used in construction. Because of its hollow cross-section, it is widely used as a pipeline for conveying fluids, such as pipelines for conveying oil, natural gas, coal gas, water and certain solid materials.

Welded pipe

Welded pipe is widely used in tap water engineering, petrochemical industry, chemical industry, electric power industry, agricultural irrigation, urban construction and other fields. In the field of construction, welded pipe is often used in steel structure frames, supports and guardrails; in the field of pipeline transportation, welded pipe is used to convey fluid media such as water, gas, oil, etc.

Welded pipe is also used in machinery manufacturing, automobile manufacturing, railways and aerospace. In these fields, welded pipes are widely used due to their high strength, good toughness, corrosion resistance and easy processing.