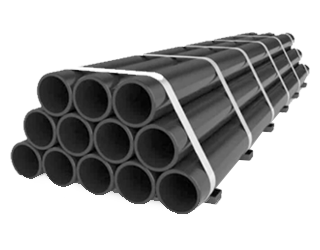

Structural Steel Pipe Detail:

Shape:square,rectangular,round,shaped

Size:φ:10.3-3620mm W.T.: 0.5-60mm for Round Structural Pipe.

O.D.:10*10-1200*1200mm W.T.:0.5-60mm for square steel pipes.

O.D.:10*15-800*1200mm W.T.:0.5-60mm for rectangular steel pipes.

For irregular pipes, customize the outer diameter and wall thickness.

Length:Customers can customize the length according to their own needs.

Steel Grade:.Gr.A/B/C,S235/275/355/420/460,A36,SS400,Q195/235/355,STKR400/490,300W/350W.

Standard:ASTM. A500/A501/A53/A106,EN10219/10210,JIS G3466,GB/T6728/3094/9711 AS1163, CSA G40.20/G40.21.

Surface Treatment:.Bare,oil,painted,galvanized,etc.

Pipe End:Pipe end threading, punching, expanding, reducing, beveling, flat mouth, etc.

MOQ:2-5Tons.

Capacity:10 million tons per year.

Packaging:Oil coated and PVC cloth.

Port of origin:Tianjin Port.

Payment term:TT/LC

Samples:Free within 20cm length Free within 20 centimeters, shipping cost to be borne by oneself