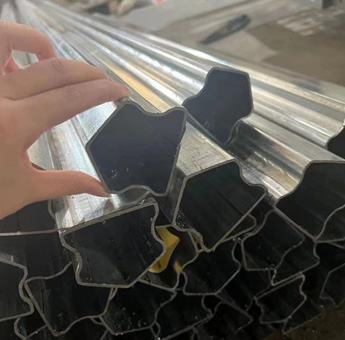

500 * 500mm square tube straight out unit

Can achieve electronic control automation from type change to finished square tube production.

In order to meet the requirements of various structural steel pipes and profiles from global steel pipe customers, Yuantai Derun has invested a large amount of funds in the research and development of production equipment and process technology. We are not only able to produce carbon steel pipes, square steel pipes, rectangular steel pipes, circular steel pipes, ERW pipes, LSAW pipes, spiral welded steel pipes, hot-dip galvanized steel pipes, pre galvanized steel pipes, zinc aluminum magnesium coated steel pipes, but also can produce photovoltaic brackets, C-shaped steel, Z-shaped steel, zinc aluminum magnesium steel coils and other products.

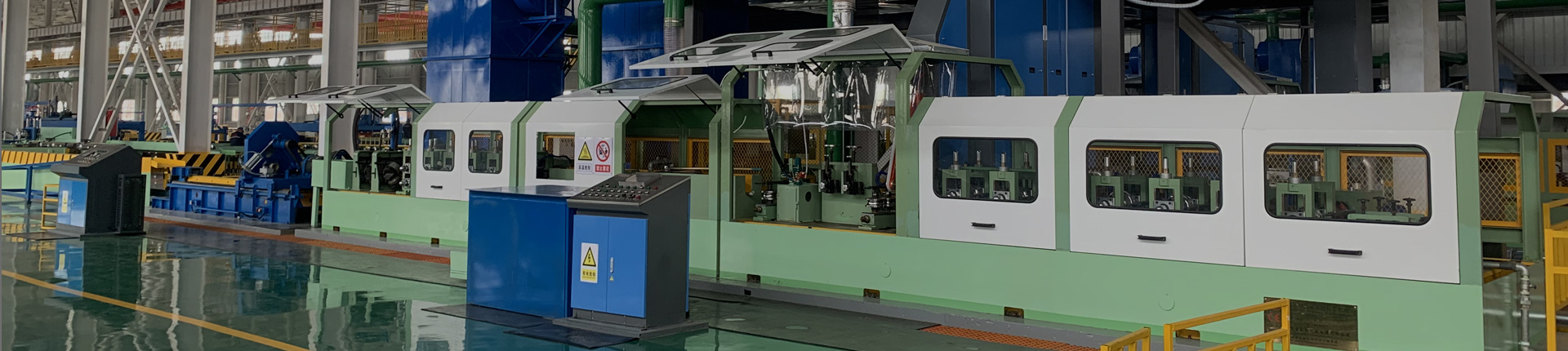

Let's take a look at our manufacturing factory. Currently, we have 8 factories located in Tianjin and Tangshan.

Tianjin Yuantai Industry and Trade, was established in 2002 as a professional manufacturer of rectangular tubes. It is the predecessor of Tianjin Yuantai Derun Steel Pipe Manufacturing Group, with 4 high-frequency pipe production lines and an annual output of 800000 tons. All adopt high-frequency welding and cold bending one-time forming technology, with advanced technology, excellent equipment, strong technical force, and complete quality testing to ensure the production of high-quality products that meet customer satisfaction. In addition, there are several hot-dip galvanized steel pipe production lines with a saturated production capacity of around 1 million tons.

Next is our second factory, also located in Tianjin, which produces pre galvanized steel pipes. It has 9 pre galvanized steel pipe production lines and an annual production capacity of around 750000 tons.

Is the production base for large-diameter square and circular pipes of Yuantai Derun φ 1420 double-sided Submerged arc welding straight seam round pipe production line also filled the blank of similar steel pipe products in Tianjin when it was introduced. The square tube direct molding unit with a capacity of 500*500mm, 300*300mm, and 200*200mm is currently one of the best in China, achieving electronic control automation from mold replacement to finished products.

opposite the third factory is the fourth factory. The fourth factory mainly produces small diameter square rectangular tubes. The newly built office building, research and development building, and testing center of the group headquarters are all shown in this photo.

The production line is equipped with a zinc aluminum magnesium steel pipe production line, a hot-dip galvanized steel pipe production line, a black high-frequency welded pipe production line, a zinc aluminum magnesium steel coil production line, an ERW welded steel pipe production line, a photovoltaic support production line, and a steel profile production line, with an annual production capacity of up to 5 million tons. At present, the Tangshan factory area has been officially put into operation. The following picture shows the renderings of the renovated Tangshan Yuantai Derun factory office building.

Can achieve electronic control automation from type change to finished square tube production.

Can achieve electronic control automation from model change to finished square tube production.

Can achieve electronic control automation from model change to finished square tube production.

Can produce square tubes with a diameter less than 200 * 200mm and a thickness of 0.5-16mm

Can be used to perform stress relieving treatment on steel pipes.

Can perform stress relief treatment on four arc corners of steel pipe products.

Capable of producing φ 219-3620mm spiral welded steel pipe.

Capable of producing φ 355.6-1420mm straight seam large circular pipe.

for zinc aluminum magnesium steel pipes, capable of producing zinc aluminum magnesium square pipes (10 * 10-200 * 200mm THK: 0.5-2.75mm), zinc aluminum magnesium rectangular pipes (10 * 15-100 * 300mm THK: 0.5-2.75mm), and zinc aluminum magnesium circular pipes( φ 10.3-200mm THK: 0.5-2.75mm).

Can perform hot dip galvanizing treatment on square pipes, rectangular pipes, circular pipes, and steel parts of any caliber. The thickness of the zinc layer can be processed according to customer requirements.

Can perform pickling treatment on steel coils or steel parts.