Steel pipes:definition,process,properties,type and testing

Steel pipes are a very commonly used metal building material, but many people still have a lot of knowledge about the types, characteristics, testing methods, production processes, and other aspects of steel pipes. Today, this article on steel pipes will give you a comprehensive answer.

1.What Is Steel Pipe?

Steel pipes are hollow tubes made of steel, used for fluid transportation or structural support. They are often used in construction, pipelines, and various industrial applications.

2. What Is A Steel Pipe Made Up Of?

The main material of a steel pipe is steel, which is mainly composed of iron and carbon elements. In addition, steel also contains manganese, silicon, phosphorus, sulfur, tungsten, zirconium, vanadium. Sometimes, in order to provide steel with more required attribute parameters, steel is artificially added with alloying elements such as chromium (Cr), molybdenum (Mo), cobalt (Co), nickel (Ni), etc.

Various chemical components have a significant impact on the physical properties of steel pipes.

1. Carbon (C): The higher the carbon content, the higher the hardness of the steel pipe, but the toughness and weldability will correspondingly decrease.

2. Silicon (Si): The content of silicon affects the tensile strength and cold bending performance of steel pipes. If the content is too high, it will reduce the cold bending performance, while if the content is too low, it will affect the tensile strength.

3. Manganese (Mn): The content of manganese has an impact on the toughness and hardness of steel pipes, and excessive content can reduce welding performance.

4. Phosphorus (P) and sulfur (S): The lower the content of these two elements, the better the cold working performance of the steel pipe, but the corresponding decrease in welding performance.

3.Properties Of Steel Pipes

What is the performance of steel pipes in your eyes? What are these performances, and how are they represented and measured? Let me show you the following content, and you will know.

3.1 High Strength

Steel pipes have high strength and toughness, and can withstand large external forces and pressures.

Usually, we use the following parameters to measure the strength of steel pipes, but we cannot find them completely. Please correct and criticize us.

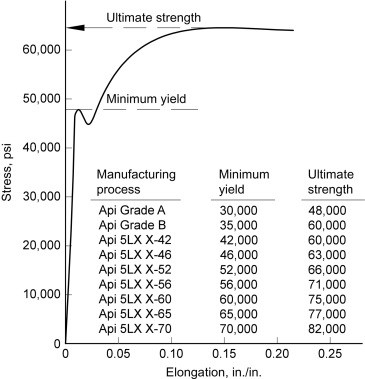

3.1.1 Steel Pipe Tensile Strength

Tensile strength refers to the maximum tensile force or tension that a steel pipe can withstand before fracture or permanent deformation occurs. The unit is Pascal or MPa.Generally speaking, in China, the tensile strength of ordinary carbon structural steel pipes is around 400MPa, while the tensile strength of high-strength alloy steel pipes can reach over 1500MPa.(The data is for reference only and does not mean that the strength of all steel pipes is at this value.)

3.1.2 Steel Pipe Yield Strength

Yield strength refers to the maximum stress that a steel pipe can withstand under tension or compression before undergoing plastic deformation. In simple terms, when external forces cause the internal stress in the steel pipe to exceed its yield strength, irreversible plastic deformation occurs.(The data is for reference only and does not mean that the strength of all steel pipes is at this value.)

Tensile Strength and Yield Strength Values Common Materials(Taked from Toolbox)

|

Material

|

Tensile Strength(MPa)

|

Yield Strength(MPa)

|

|

ASTM A53 Seamless and Welded Steel Pipe - Grade A

|

331

|

207

|

|

ASTM A53 Seamless and Welded Steel Pipe - Grade B

|

414

|

241

|

|

A106 Seamless Carbon Steel Pipe - Grade A

|

330

|

205

|

A106 Seamless Carbon Steel Pipe - Grade B | 415 | 240 |

A106 Seamless Carbon Steel Pipe - Grade C | 485 | 275 |

A252 Piling Steel Pipe - Grade 1 | 345 | 207 |

A252 Piling Steel Pipe - Grade 2 | 414 | 241 |

A252 Piling Steel Pipe - Grade 3 | 455 | 310 |

A501 Hot Formed Carbon Steel Structural Tubing - Grade A | 400 | 248 |

A501 Hot Formed Carbon Steel Structural Tubing - Grade B | 483 | 345 |

A523 Cable Circuit Steel Piping - Grade A | 331 | 207 |

A523 Cable Circuit Steel Piping - Grade B | 414 | 241 |

A618 Hot-Formed High-Strength Low-Alloy Structural Tubing - Grade Ia & Ib | 483 | 345 |

A618 Hot-Formed High-Strength Low-Alloy Structural Tubing - Grade II | 414 | 345 |

A618 Hot-Formed High-Strength Low-Alloy Structural Tubing - Grade III | 448 | 345 |

3.1.3 Steel Pipe Impact Property

The impact characteristics of steel pipes commonly referred to by people refer to their ability to withstand sudden or dynamic loads, such as when subjected to impact, vibration, or collision. This characteristic is crucial in some cases, especially when steel pipes may face sudden and strong external forces. The impact performance measures the resistance of steel pipes to fracture or damage when subjected to sudden forces.

Table 1 Minimum Impact Energy Values of Carbon Steel and Low Alloy Steel

|

Lower limit of standard tensile strength of steel(Rm/MPa)

|

Average impact energy of three standard specimens(KV2/J)

|

|

≤450

|

≥ 20

|

|

>450~510

|

≥ 24

|

|

>510~570

|

≥ 31

|

>570-630 | ≥ 34 |

>630-690 | ≥ 38 |

Note: For steel with a decrease in Rm as thickness increases, the impact energy index is determined based on the minimum thickness range of Rm for that steel.

Impact performance is the ability of a material to resist external forces and impacts.The impact performance indicators of steel include impact strength, impact toughness, and impact energy.

3.1.4 Steel Tube Elongation

In the tensile test, the percentage increase in the length of the marked distance after the steel pipe specimen is pulled out compared to the original marked distance is called the elongation of the steel pipe, symbol a. 1、 The concept of steel pipe elongation refers to the ratio of the corresponding deformation of the steel pipe after being subjected to force to its original length. It is one of the important indicators of elastic deformation of steel pipes, usually expressed as a percentage.

The calculation formula for the elongation of steel pipes is: elongation= δ L/L0 × 100% of which, δ L is the deformation of the steel pipe after being subjected to force, and L0 is the original length of the steel pipe.

3.2 Steel Pipe Hardness

Hardness describes the ability of steel pipes to resist scratches and deformation.

Common metal material hardness comparison table: Please click here to download for free

Dear readers, let's take a look at three common measurement methods for the hardness of steel pipes: Brinell hardness, Rockwell hardness, and Vickers hardness.

Firstly, Brinell hardness is one of the most widely used hardness measurement methods. Its measurement method is to observe the diameter of the indentation after applying a certain force to the steel. This method is intuitive and convenient, especially suitable for observing hard steel or thin sheets with larger indentation diameters.

Next is Rockwell hardness, which is similar to Brinell hardness but measures indentation depth. The application range of Rockwell hardness testing is very wide, especially suitable for measuring metal materials from extremely soft to extremely hard. Compared with Brinell hardness, Rockwell hardness can be directly read from the hardness table, making up for the shortcomings of the Brinell hardness method. However, the Brinell hardness method has smaller indentations and therefore higher accuracy.

Finally, Vickers hardness is mainly used to measure the surface layer hardness of thin metal materials. The Vickers hardness method combines the advantages of the Brinell hardness method and the Rockwell hardness method, overcoming their shortcomings. However, due to the relatively inconvenient operation, the application of Vickers hardness and Rockwell hardness in steel standards is relatively limited.

3.3 Steel Pipe Load Capacity and Pressure Rating

The load-bearing capacity of steel pipes under load is influenced by design and specifications.

3.3.1 Steel Pipe Load Capacity

When calculating the compressive bearing capacity of steel pipes, it is necessary to consider factors such as material strength, wall thickness, length, etc., and choose appropriate calculation methods for different cross-sectional shapes. For example, for steel pipes with circular cross-sections, the following formula can be used to calculate their compressive bearing capacity:

P = 0.72 × Fy × (D - 0.8t) × t

Where P is the critical compressive force of the pipe, Fy is the yield strength of the material, D is the outer diameter of the pipe and t is the wall thickness of the pipe.

3.3.2 Steel Pipe Pressure Rating

A What Is Steel Pipe Pressure Rating?

The pressure rating of a steel pipe is the maximum permissible internal pressure that the pipe can withstand without compromising the safety of the structural integrity of the pipe.

It is very necessary to determine the appropriate pressure rating of the steel pipe. Because it can ensure that the steel pipe is suitable for specific applications and operating conditions.

B What Are The Factors That Affect The Rated Pressure Of Steel Pipes?

The rated pressure value of steel pipes is usually determined using various factors, such as steel material, steel pipe size (outer diameter, wall thickness), temperature, and design standards or specifications that provide guidelines for calculating pressure ratings.

3.4 Steel Pipe Roughness

The rated pressure value of steel pipes is usually determined using various factors, such as steel material, steel pipe size (outer diameter, wall thickness), temperature, and design standards or specifications that provide guidelines for calculating pressure ratings.

3.4.1 What Is Steel Pipe Roughness?

Pipe roughness is the irregularity or unevenness of the internal surface of a steel pipe. It is a parameter used to describe the internal texture or roughness of a pipe and is an important feature to consider in various engineering calculations.

3.4.2 The Necessity Of Understanding The Roughness Of Steel Pipes

The roughness of the inner surface of a steel pipe affects the flow of fluid through the pipe. It can create additional frictional resistance, leading to pressure loss or increased energy requirements for the flow of fluid through the pipe. Therefore, it is critical to understand and account for steel pipe roughness in hydraulic and fluid flow analyses such as determining flow rates, pressure drop calculations and pipe sizing.

3.5 Steel Pipe Magnetic Property

Steel pipes are pipes made of steel, and their main component is iron. Iron is a ferromagnetic element with a certain degree of magnetism. Therefore, under certain conditions, steel pipes also have a certain degree of magnetism.

Steel pipes can exhibit different magnetic properties based on their composition and manufacturing process. Generally speaking, steel itself does not have magnetism, but it can be made magnetic through various methods.

3.6 Steel Pipe Ductility

3.6.1 What Is Steel Pipe Ductility?

The ductility of a steel pipe is its ability to deform or stretch under tensile stress without breaking. Ductility is an important property of steel pipe as it enables the pipe to withstand external forces and absorb energy without failing. It ensures that the pipe can be bent, shaped or welded without breaking, making it versatile and suitable for a variety of applications.

3.6.2 What Are The Key Factors Affecting The Ductility Of Steel Pipes?

The ductility of steel tubes is affected by several factors, including the particular type of steel, the manufacturing process and any additional alloying elements. For example, carbon steel tubes typically exhibit good ductility, although the addition of elements such as manganese or silicon can further enhance this property. Alloy steels, such as low alloy steels and stainless steels, typically have improved ductility due to their specific chemical composition.

The ductility of a steel pipe also depends on its heat treatment. Heat treatment processes such as annealing or tempering can improve the microstructure of steel and increase its ductility. In addition, cold working operations, such as cold drawing or cold rolling, can improve ductility by reducing grain size and introducing dislocations.

3.7 The Conductivity Of Steel Pipes

Due to the presence of a large amount of iron element in steel pipes, they have good conductivity. This is also one of the reasons why steel pipes are widely used in power transmission and communication equipment.

3.8 Thermal Conductivity Of Steel Pipes

The thermal conductivity of steel pipes is also very good, due to the large amount of metal elements contained in the pipes, which can quickly transfer heat and make the pipes have good heat dissipation effects.

Common types of steel pipe include carbon steel pipes,stainless steel pipes,alloy steel pipes,seamless steel pipe, spiral steel pipe, galvanized steel pipe, square steel pipe, rectangular steel pipe, round steel pipe, ERW steel pipe, LSAW steel pipe, zinc-aluminum-magnesium coated steel pipe and so on.

4.1 Carbon Steel Pipes

Carbon steel pipe is a common type of steel pipe in the steel pipe category. Do you know the definition, type, and purpose of carbon steel pipe?

4.1.1 What Is Carbon Steel Pipe?

Carbon steel pipe refers to a steel pipe with a carbon content between 0.08% and 2.11%. It is the most basic and common type of steel pipe.Carbon steel pipes are made by piercing steel ingots or solid round steel into capillary tubes, which are then hot-rolled, cold-rolled or cold-rolled. Carbon steel pipes play an important role in world's steel pipe industry.

4.1.2 Types Of Carbon Steel Pipe

There are three main types of carbon steel pipes:

Low carbon steel pipes:We refer to steel pipes made of low-carbon steel as low-carbon steel pipes. Low carbon steel (C ≤ 0.25%), commonly known as soft steel, is easy to accept various processing such as forging, welding, and cutting. Commonly used in manufacturing chains, rivets, bolts, shafts, etc.

Medium carbon steel pipe:

Hollow sections made of medium carbon steel are called medium carbon steel pipes. Medium carbon steel (0.25%<C ≤ 0.6%), available in various products such as killed steel, semi killed steel, and boiling steel. Divided by quality into ordinary carbon structural steel and high-quality carbon structural steel. The hot working and cutting performance of medium carbon steel is good, but the welding performance is poor. The strength and hardness are higher than those of low-carbon steel, but the plasticity and toughness are lower than those of low-carbon steel. It can be used directly as hot-rolled and cold-rolled materials without heat treatment, or after heat treatment. Quenched and tempered medium carbon steel has good comprehensive mechanical properties. So in various applications of medium strength, medium carbon steel has been widely used, not only as a building material, but also in the manufacture of various mechanical parts.

High carbon steel pipes:

The production material of high carbon steel pipes is raw materials such as high carbon steel. High carbon steel (C>0.6%) is often used as tool steel, with a carbon content ranging from over 0.60% to less than 1.70%, and can be quenched and tempered. The higher the carbon content, the greater the hardness and strength, but the plasticity decreases (in addition, iron carbon alloys with a carbon content of 2.1% -4.5% are generally referred to as cast iron)

4.2 Alloy steel pipes

Alloy pipe is a steel pipe made of alloy steel.

4.2.1 What Is Alloy Steel Pipe?

Alloy pipes are defined as steel pipes based on the materials used in production (i.e. materials), and as the name suggests, they are pipes made of alloys.

4.2.2 Types Of Alloy Steel Pipes

Alloy pipes can be divided into: low alloy pipes, alloy structural pipes, high alloy pipes, high-strength alloy pipes, bearing pipes, heat-resistant and acid resistant alloy pipes, high-temperature alloy pipes,Chrome Moly Pipe,Nickel Alloy Pipe,Inconel Pipe,Hastelloy Pipe,Duplex Stainless Steel Pipe,Super Duplex Stainless Steel Pipe,Alloy 20 Pipe (Carpenter 20),Titanium Alloy Pipe,Alloy Steel P91 Pipe,Alloy Steel P5 Pipe and so on.

4.2.3 What Is Alloy Steel Pipe Used For?

Alloy steel pipes are mainly used for high-pressure and high-temperature pipelines and equipment such as power plants, nuclear power plants, high-pressure boilers, high-temperature superheaters, reheaters, etc

4.2.4 Alloy Steel Pipe Advantage

The biggest advantage of alloy steel pipes is that they can be 100% recycled, which is in line with the national strategy of environmental protection, energy conservation, and resource conservation. The national policy encourages the expansion of the application field of high-pressure alloy pipelines. The proportion of alloy tube consumption in China's total steel consumption is only half that of developed countries, and the expansion of alloy tube usage provides broader space for industry development. According to the expert group of the Alloy Pipe Branch of the China Special Steel Association, the annual demand for long and high-pressure alloy pipes in China will increase by 10-12% in the future.

4.2.5 Materials Of Alloy Pipes

The materials of alloy pipes generally include: 16-50Mn, 27SiMn, 40Cr, 12-42CrMo, 16Mn, 12Cr1MoV, T91, 27SiMn, 30CrMo, 15CrMo, 20G, Cr9Mo, 10CrMo910, 15Mo3, 15CrMoV, 35CrMoV, 45CrMo, 15CrMoG, 12CrMoV, 45Cr, 50Cr, 45CrNiMo, etc

4.3 Stainless steel pipes

Stainless steel pipe is a pipe material made of stainless steel. Stainless steel pipes can also have square, rectangular, and other shapes. His application scope is used for pipelines transporting fluids or some steel structure buildings. Mainly used in industries such as petroleum, chemical, medical, food, light industry, mechanical instruments, and mechanical structural components. Stainless steel pipes are made of steel billets with acid and heat resistance grades, which are heated, perforated, sized, hot-rolled, and cut.

Stainless steel pipes can be classified along multiple dimensions:

4.3.1.Material Classification:

Stainless steel pipes are divided into seamless and welded types. They further include categories like ordinary carbon steel pipes, high-quality carbon structural steel pipes, alloy structural pipes, alloy steel pipes, bearing steel pipes, and stainless steel pipes.

4.3.2 Production Process Classification:

Production processes for stainless steel pipes include hot-rolled, extruded, cold-drawn, and cold-rolled, each forming a basic type.

4.3.3 Cross-Sectional Shape Classification:

Stainless steel pipes exhibit circular and non-circular cross-sectional shapes. The latter encompasses rectangular, rhombic, elliptical, hexagonal, octagonal, and various asymmetric section pipes.

4.3.4 Pipe End Shape Classification:

Stainless steel pipes can have plain ends or threaded ends (pipes with threads), with the threaded category further divided into regular threaded pipes and special threaded pipes.

4.3.5 Application Classification:

Stainless steel pipes find extensive applications, including but not limited to well pipes, pipeline pipes, boiler pipes, structural pipes, hydraulic pillar pipes, gas cylinder pipes, geological pipes, and chemical industry pipes (such as high-pressure fertilizer pipes and petroleum cracking pipes), as well as pipes for shipbuilding.

4.4 Galvanized Steel Pipes:

4.4.1 What Is Galvanized Steel Pipe?

Generally speaking, galvanized steel pipe is a type of steel pipe with a zinc layer on its surface.

4.4.2 Type Of Galvanized Steel Pipe

The types of galvanized steel pipes can be roughly divided into two categories: hot-dip galvanized steel pipes and pre galvanized steel pipes.

4.4.3 Hot Dip Galvanized Steel Pipes Vs Pre Galvanized Steel Pipes

Zinc Layer Thickness

The zinc layer of pre galvanized steel pipes is relatively thin, while the zinc layer of hot-dip galvanized steel pipes is relatively thick.

Price

Due to the high zinc layer thickness of hot-dip galvanized steel pipes, the amount of zinc added is greater than that of pre galvanized steel pipes, so the price of hot-dip galvanized steel pipes is higher than that of pre galvanized steel pipes.

Life

Normally, the lifespan of ordinary pre galvanized steel pipes is 2-5 years. The service life of hot-dip galvanized steel pipes is 20-50 years.

4.5 Seamless Steel Pipes

4.5.1 What Is Seamless Steel Pipe?

Seamless steel pipe is a steel pipe made by piercing the entire round steel without any welds on the surface.

4.5.2 Types of Seamless Steel Pipe

Seamless steel pipes can be classified according to different classification dimensions:

-》Production Methods:

Seamless steel pipes can be categorized based on production methods, including hot-rolled pipes, cold-rolled pipes, cold-drawn pipes, and extruded pipes.

-》Shape Classification:

Seamless steel pipes can also be classified according to their shapes, namely round pipes and special-shaped pipes. Special-shaped pipes include not only common square and rectangular pipes but also elliptical pipes, semi-circular pipes, triangular pipes, hexagonal pipes, convex pipes, plum blossom pipes, and more.

-》Material Classification:

Seamless steel pipes can be categorized by material composition into ordinary carbon structural pipes, low-alloy structural pipes, high-quality carbon structural pipes, alloy structural pipes, stainless steel pipes, and others.

-》Specialized Applications:

Seamless steel pipes serve specific purposes, including geological pipes, oil pipes, low and medium-pressure boiler steel pipes, high-pressure boiler steel pipes, alloy steel pipes, stainless steel pipes, petroleum cracking pipes, geological steel pipes, and more.

4.5.3 Seamless Steel Pipe Application

Seamless steel pipes have higher strength and pressure bearing capacity, making them an ideal choice for transporting fluids or gases under high pressure. They are commonly used in the oil and gas industry, petrochemical plants, and power generation.

4.6 Welded Steel Pipes

4.6.1 What Is Welded Steel Pipe?

Welded pipe is a steel pipe made by welding steel plates or strips after being rolled and formed. The billet used for welding steel pipes is steel plates or strips.

4.6.2 Type Of Welded Steel Pipe

ERW (Electric Resistance Welded) Steel Pipes

ERW steel pipe is a type of welded steel pipe formed by rolling or winding steel plates, and then welding the edges together using resistance. ERW pipelines are typically used for medium to low pressure applications, such as water and natural gas transportation.

Resistance welding refers to the method of using the resistance heat generated by the current passing through the welded part and the contact area as a heat source to locally heat the welded part, while applying pressure for welding. When welding, there is no need for filler metal, with high productivity, small deformation of the welded parts, and easy automation.

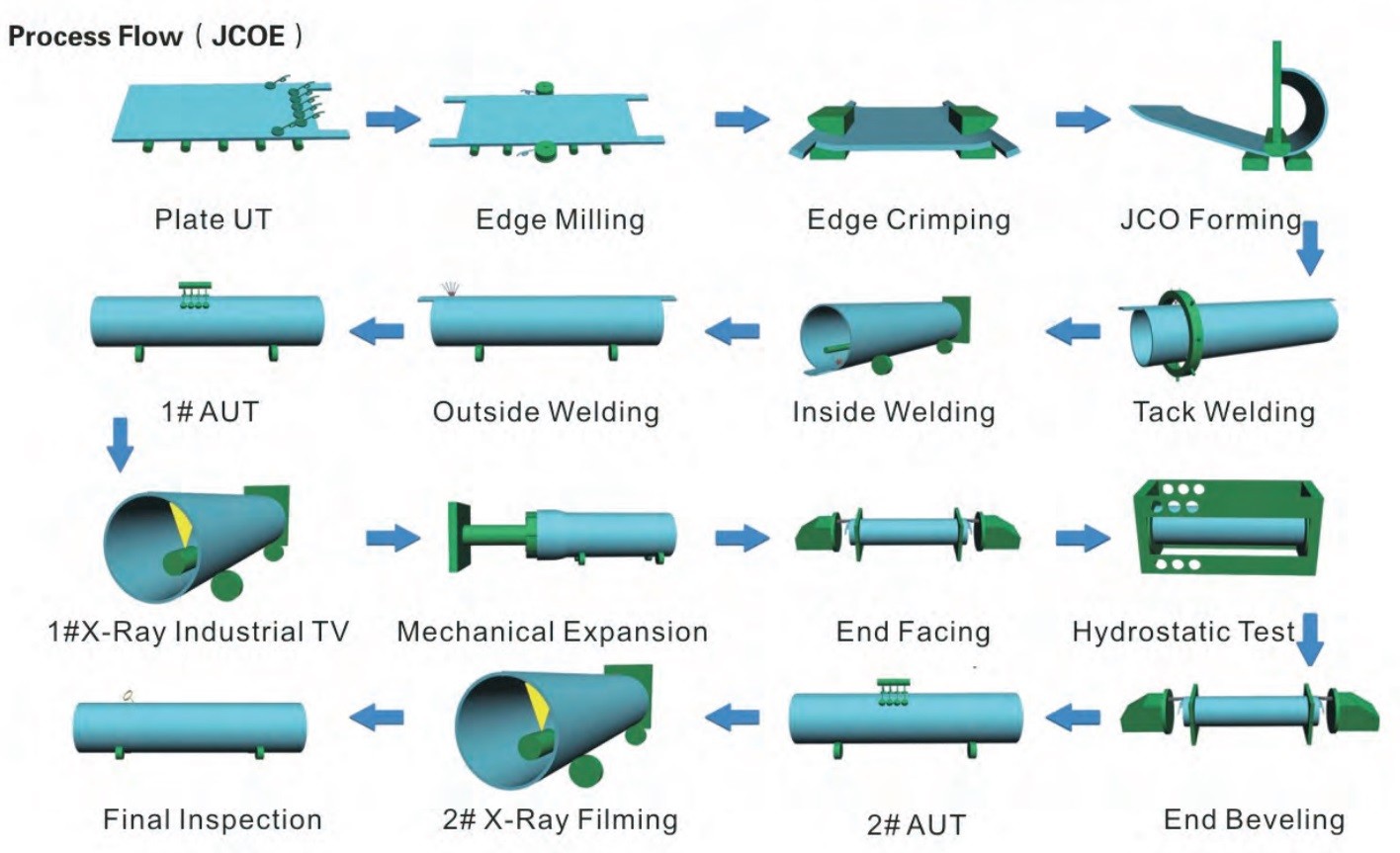

LSAW (Longitudinal Submerged Arc Welded) Steel Pipes

LSAW steel pipe (Longitudinally Submerged Arc Welding, abbreviated as LSAW) is a professional expression term for straight seam submerged arc welded steel pipe. It is a pipe produced by using a single medium thick plate as raw material, rolling the steel plate into a billet in a mold or forming machine, using double-sided submerged arc welding method and expanding the diameter.

The welding process used for submerged arc welded straight seam steel pipes is submerged arc welding technology, which uses filler welding and particle protection flux for submerged arc welding. The diameter produced can reach 1500mm. LSAW is the English abbreviation for submerged arc welded straight seam steel pipe. The production processes of submerged arc welded straight seam steel pipe include JCOE forming technology and roll forming submerged arc welding technology.

SSAW(Spiral Submerged Arc Welded) Steel Pipes

Spiral welded pipe: It is made by rolling low-carbon carbon structural steel or low alloy structural steel strip into a pipe blank at a certain helix angle (called forming angle), and then welding the pipe seam to produce large-diameter steel pipes using narrower strip steel.

It can produce large-diameter steel pipes using narrower strip steel. The specifications are represented by the outer diameter and wall thickness, and the welded pipe should ensure that the water pressure test, tensile strength of the weld seam, and cold bending performance meet the requirements.

5.Steel Pipe Manufacturing Process

The development of steel pipe production and manufacturing technology originated from the popularization and development of bicycles, the development of petroleum in the 19th century, and the prosperity of the manufacturing industry after World War II, which promoted the development of steel pipes in categories, production, quality, and other aspects. Do you know what are the current manufacturing processes for steel pipes? Let me show you below.

Usually, steel pipes are divided into two types based on production methods: welded steel pipes and seamless steel pipes.

5.1 Welding Pipe Manufacturing Process

The three most popular production processes for welded pipes are currently ERW, LSAW, and SSAW.

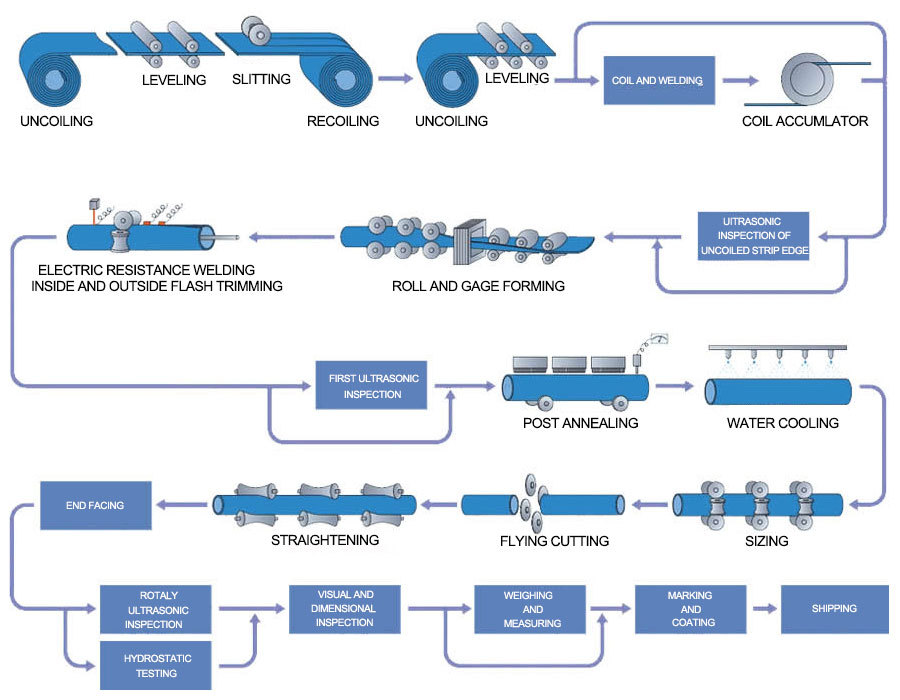

5.1.1 ERW Pipe Manufacturing Process

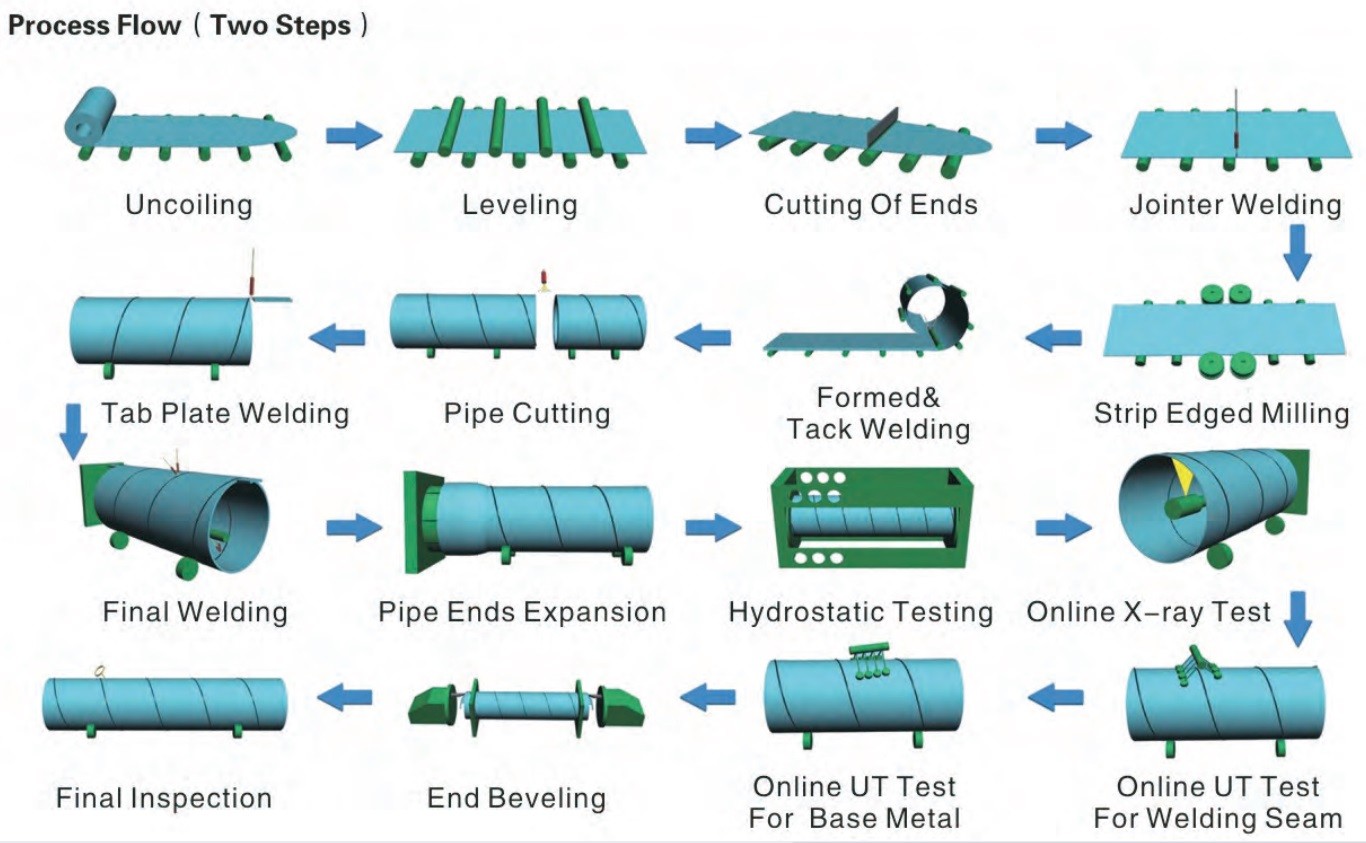

Straight seam Electric Resistance welded (ERW) pipe is a hot rolled coil through the forming machine after forming, the use of high-frequency current skin effect and neighborhood effect, so that the edge of the billet is heated and melted, in the extrusion rollers under the action of the pressure welding to achieve the production. This process has been upgraded and has become the most popular steel pipe production process nowadays.The production process is as follows:(See Graph below)

5.1.2 LSAW Pipe Manufacturing Process

Longitudinal submerged arc welded (LSAW) pipes are generally made from steel plates and undergo different forming processes, including double-sided submerged arc welding and post weld expansion to form welded pipes.(See Graph below)

5.1.3 SSAW Pipe Manufacturing Process

SSAW spiral submerged arc welded pipe, submerged arc welding (including submerged arc welding and electric slag welding) is an important welding method. Its inherent advantages of stable welding quality, high welding productivity, no arc light and little smoke and dust make it the main welding method in the production of important steel structures such as pressure vessels, pipe sections, and box beams and columns.

5.2 Seamless Steel Pipe Manufacturing Process

Seamless steel pipes are known as the "blood of industry". Do you know what are the manufacturing processes for seamless steel pipes? The following chart will help you unravel this mystery.

Seamless pipe production method | Basic process | ||

|

Bore a hole

|

Tube rolling

|

||

|

Hot Rolling Process

|

Rolling on an automatic pipe rolling mill |

Piercing of round tube blanks on a two roll piercing machine |

Rolling with short head on a two roll pipe mill with feeding rollers |

|

Rolling on a periodic pipe rolling mill

|

Piercing round steel ingots or billets on a two roll piercing machine; Perforation of square or polygonal steel ingots on a hydraulic press |

In the period with variable cross-section hole patterns Rolling with long core rod on pipe rolling mill |

|

Rolling on a continuous pipe rolling mill | Round tube blank in three or two roll type Perforation on the punching machine; Continuous casting of square billets or square steel ingots in two Piercing on roller pressure piercing machine | On 7-9 continuous pipe rolling mills Core rod rolling; Attached tension reducing machine | |

Rolling on a three roll pipe rolling mill | Piercing the round tube blank on a two roll piercing machine; Continuous casting billet Piercing on a three roll piercing machine | Rolling with long core rod on a three roll oblique rolling mill | |

Rolling on an extended pipe rolling mill | Piercing on a two roll piercing machine | On a disc shaped tension guide roller On a two roll oblique rolling mill with a long core rod rolling | |

Rolling on planetary pipe rolling mill | Using cast hollow tube blanks | Rolling on planetary pipe rolling mill | |

Pipe Jacking | Punch into a cup shaped capillary on a hydraulic press | ||

Extrusion method | After heating the tube blank, it is extruded into shape on an extruder | Can continue rolling or drawing | |

Cold rolling method | Rolling of hot-rolled pipe materials on a cold rolling mill | ||

Cold drawing method | Drawing of hot-rolled or cold-rolled pipe materials on a cold drawing machine | ||

6.Benefit Of Steel Pipes

A. Durability and strength

As a building material, steel pipes have the greatest advantage of high strength. Because steel is a very sturdy material that can support more weight, steel pipes are more suitable for bearing the weight of building structures than most other building materials. Steel pipes are widely used in construction fields such as bridges and high-rise buildings, which can withstand huge loads and also increase the seismic resistance of the entire structure.

B. Resistance to corrosion

Due to the susceptibility of steel to rust, steel pipes need to undergo anti-corrosion treatment to ensure their service life and performance. The strong corrosion resistance of steel pipes is another advantage. After a series of anti-corrosion treatments, the service life of steel pipes can be greatly extended. The commonly used anti-corrosion treatment methods include hot-dip galvanizing, electrogalvanizing, epoxy coating, etc. These treatment methods can effectively prevent rusting and corrosion of steel pipes, thereby protecting their service life.

C. Cost-effectiveness and longevity

Steel pipe is known for its cost-effectiveness and longevity, making it a popular choice in various industries. The use of steel pipes ensures a balance between affordable pricing and durable performance. Steel's inherent strength and resistance to corrosion make it suitable for demanding applications, reducing maintenance and replacement costs. The longevity of steel pipe is further enhanced through proper installation techniques and proactive maintenance practices. This combination of cost-effectiveness and longevity makes steel pipe an attractive option in infrastructure projects, plumbing systems, oil and gas transportation, and various industrial applications where durability and efficiency are paramount

D. Environmentally

The manufacturing and processing process of steel pipes is more environmentally friendly and energy-saving compared to other materials. Using steel pipes as structural fittings can help reduce the use of raw materials such as wood and stone, thereby causing less burden on the environment

E. Easy to process

Steel pipes not only achieve high strength and corrosion resistance, but are also easy to process. Compared to other materials, steel pipes can be easily processed into the desired shape and size. Especially for complex shapes, the processing ability of steel pipes is more prominent, which can meet various engineering needs.

7.Application Of Steel Pipe

The application of steel pipes is very extensive, mainly in fields such as construction, transportation, petrochemicals, machinery manufacturing, etc.

A. Construction

Steel pipes are widely used in high-end buildings, sports venues, bridges, tunnels, airports, docks, stations and other places.

B. Transportation

Steel pipes are widely used in the support, fixation, and construction of various transportation facilities such as highways, railways, and waterways

C. Petrochemical industry

Oil and gas transmission pipelines are the main application areas in the petrochemical industry. In addition, steel pipes are also used in liquid and gas storage and transportation facilities, petrochemical machinery equipment, petroleum drilling equipment, and other aspects.

D. Machinery manufacturing

A large amount of mechanical manufacturing development requires steel pipes as materials, and steel pipes are also a necessary element in mechanical manufacturing. For example, steel pipes are used to manufacture micro power machinery and its components, cold bending elbows, automotive spokes, motorcycle columns, and so on.

8.Steel Pipe Measurements

The measurement method for steel pipes generally requires specialized tools. Below, we will take you to see how steel pipes are measured?

8.1.How To Measure The Size Of Steel Pipes?

To measure the size of a steel pipe, you will typically need to measure its inside diameter, outside diameter, thickness, and length. Here's how you can do it:

8.1.1 Inside Diameter:

The inside diameter of a steel pipe refers to the distance across the circular opening of the pipe. This can be measured using a caliper or a measuring tape. Simply insert the caliper jaws or tape measure into one end of the pipe and measure the distance to the opposite side.

8.1.2 Outside Diameter:

The outside diameter of a steel pipe is the total width of the pipe, including the thickness of the pipe walls. To measure the outside diameter, you can use the same method as for the inside diameter—insert the caliper jaws or measuring tape and measure from one side of the pipe to the other.

8.1.3 Wall Thickness:

The thickness of a steel pipe refers to the distance between the inner and outer surfaces of the pipe walls. You can measure the thickness using a caliper or micrometer. Place the jaws of the caliper or micrometer on either side of the pipe wall, making sure to include the entire thickness, and take the measurement.

8.1.4 Length

The length of a steel pipe can be measured using a measuring tape or a measuring wheel. Simply stretch the tape measure or roll the measuring wheel along the length of the pipe to determine the distance.

8.2.How To Calculate The Volume Of Steel Pipes?

To calculate the volume of a steel pipe, you will need to know the measurements of the pipe: the inside diameter (ID) and the length of the pipe. Follow these steps:

A.Determine the Inside Radius (IR):

The most basic method of calculating the inner diameter of the steel pipe is based on the outer diameter and wall thickness of the pipe to calculate the inner diameter. Specific calculation method is as follows: inner diameter = outer diameter -2 × wall thickness. For example, the outer diameter of 50 mm, wall thickness of 3 mm, the inner diameter of the steel pipe is 50-2 × 3 = 44 mm.

B.Calculate the Cross-Sectional Area (CSA) of the Pipe:

Use the formula: CSA = π * IR^2 (Note: π is a mathematical constant approximately equal to 3.14159)

C.Calculate the Volume of the Pipe:

Multiply the Cross-Sectional Area (CSA) by the length of the pipe. Volume = CSA * Length

By following these steps, you can calculate the volume of a steel pipe. Make sure to use consistent units of measurement (e.g., centimeters or inches) for all the dimensions to get an accurate volume result.

8.3.How To Calculate The Weight Of Steel Pipes?

The theoretical weight calculation formula for various types of steel is as follows:

8.3.1. Calculation of steel pipe weight.

Formula: Outer diameter wall thickness (mm) × Wall thickness (mm) × 0.02466 × Length.

Example: Steel pipe 114mm (outer diameter) × 4mm (wall thickness) × 6m (length).

Calculation: (114-4) × four × 0.02466 × 6=65.102kg.

8.3.2. Calculation of the weight of round steel.

Formula: Diameter (mm) × Diameter (mm) × 0.0617 × Length.

Example: Round steel Φ 20mm diameter × 6m (length.

Calculation: 20 × 20 × 0.0617 × 6=14.808kg.

8.3.3. Calculation of the weight of square steel.

Formula: Edge width (mm) × Edge width (mm) × Length (m) × 0.00785.

Example: 50mm square steel (edge width) × 6m (length).

Calculation: 50 × fifty × six × 0.00785=117.75kg.

8.3.4. Calculation of Square Tube Weight(square tube weight calculator).

Formula: Edge width (mm) × four × thick × 0.00785 × Length.

Example: Fangtong 50mm × 5mm thick × 6m (length).

Calculation: 50 × four × five × 0.00785 × 6=47.1kg.

8.3.5. Calculation of the weight of flat steel

Formula: Edge width (mm) × Thickness (mm) × Length (m) × 0.00785.

Example: Flat steel 50mm (edge width) × 5.0mm thick × 6m (length).

Calculation: 50 × five × six × 0.00785=11.775kg.

8.3.6. Formula for calculating the weight of rectangular tubes

Formula:[2 × (Side length 1+Side length 2)/3.14- Wall thickness] × wall thickness × length × 0.02466

Example:Rectangular tube:40*60*2.0mm 6M(length).

Calculator:[2*(40+60)/3.14-2]*2*6*0.02466=9.424 kg

9.Steel Pipe Temperature Expansion

The size of the expansion coefficient of steel pipes depends on the type of pipeline material and the temperature range. Generally speaking, the expansion coefficient of metal materials is relatively large, while the expansion coefficient of plastic materials is relatively small. The following are the expansion coefficient ranges for some common pipeline materials:

Carbon steel: 10.8 × 10 ^ -6/℃

Stainless steel: 16.0 × 10 ^ -6/℃

It should be noted that the size of the expansion coefficient of steel pipes is not only related to the material of the steel pipe, but also to factors such as the usage environment, installation method, and length of the steel pipe. During the design and installation of steel pipes, the material and expansion joint of the steel pipes should be reasonably selected based on the actual situation and requirements, and the corresponding expansion coefficient should be calculated to ensure the safe and stable operation of the pipeline connection.

10.Steel Pipe Grades

Steel pipes are available in various grades based on their composition. The classification method includes carbon steel pipe grade, alloy steel pipe grade, and stainless steel pipe grade. Here are some common steel pipe grades:

10.1 Carbon Steel Pipe Grades:

ASTM A53, ASTM A500, ASTM A501, ASTM A106: These grades are commonly used for carbon steel pipes

10.2 Stainless Steel Pipe Grades:

ASTM A312, 904L, 304, 316L: These grades are commonly used for stainless steel pipes.

10.3 Alloy Steel Pipe Grades:

ASTM A335/213, ASTM A333 Grade 6, ASTM A795 Grade E, ASTM A572 Grade 50, ASTM A519 Grade 4130, ASTM A516 Grade 60, ASTM A252 Grade 3: These grades are commonly used for alloy steel pipes.

10.4 What Are The Grades Of Steel Pipes Classified By Industry?

Furthermore, steel pipe grades can also be classified according to industry standards:

ASTM A36: The most common low-carbon structural steel in the United States.

ASTM A283: Low to medium strength carbon steel plates for general engineering.

ASTM A514: Medium-strength, high-strength molybdenum-containing alloy steel plate.

ASTM A572: Medium to high-strength, low-alloy cast steel for building structures, bridges, ships, etc.

ASTM A573: Medium-strength manganese-containing carbon steel plates with high supply quantity.

GB Standard Carbon Steel Grades:

Q195: Non-alloy steel for general structural use.

Q215: Low carbon steel for general structural use.

Q235: Medium carbon steel for general structural use.

Q255: Medium carbon alloy steel for general structural use.

Q275: High-strength structural steel.

JIS Standard Carbon Steel Grades:

SS400: Steel for general structures, with a yield point strength higher than Q235.

S45C: Steel used for manufacturing components such as gears, bearings, and shafts.

S50C: High-quality carbon structural steel for manufacturing mechanical components.

S55C: Medium strength and high-quality carbon structural steel, typically used in sheet and strip materials.

Apart from these standards, there are other commonly used carbon steel grades as well, such as those specified in DIN, BS, and NF standards.

In summary, carbon steel pipes have various grades available, and the selection of a particular grade depends on the specific application requirements

11.Steel Pipe Standards

Steel pipe standards refer to a set of specifications that define the technical requirements for the manufacturing and testing of steel pipes. These standards ensure consistency and quality across the industry, allowing pipes to meet specific criteria for dimensions, material properties, performance, and safety.Some widely recognized steel pipe standards include:

11.1 American Society for Testing and Materials (ASTM)

ASTM standards cover a wide range of steel pipe types, including seamless and welded pipes. Popular ASTM standards for steel pipes include A53, A106, A333, A335, A312, and A500,etc.

11.2 International Organization for Standardization (ISO)

ISO standards provide global guidelines for steel pipe production, quality control, and performance. ISO 3183 and ISO 11960 are commonly used for pipes used in the oil and gas industry.

11.3 American Petroleum Institute (API):

API standards are specifically developed for the oil and gas industry. Pipe standards like API 5L and API 5CT define requirements for line pipes, casing, and tubing used in oil and gas exploration, production, and transportation.

11.4 European Standards (EN):

EN standards are widely used in Europe and cover various aspects of steel pipes, including dimensions, materials, and testing. Popular EN standards for pipes include EN 10210, EN 10219, EN 10216, and EN 10255.

11.5 Japanese Industrial Standards (JIS):

JIS standards are used in Japan and often adopted by other Asian countries. JIS G3466,JIS G3454, JIS G3455, JIS G3456, and JIS G3458 are some examples of JIS standards for steel pipes.

These are just a few examples of the numerous standards that exist worldwide. Each standard specifies the requirements for factors like chemical composition, mechanical properties, dimensional tolerance, heat treatment, non-destructive testing, and marking.

Compliance with steel pipe standards is crucial for ensuring compatibility, reliability, and safety in various industries, including oil and gas, construction, water utilities, and automotive. By adhering to these standards, manufacturers, suppliers, and users can have confidence in the quality and performance of steel pipes for their specific applications.

12.Steel Pipe Handling Methods

The processing technology of steel pipes largely determines the quality and performance of steel pipes, so the research and application of steel pipe processing technology is of great significance

12.1 Steel Pipe Joining Methods

There are many methods for connecting steel pipes, including welding, threaded connections, and clamp connections.

12.2 How To Cut Steel Pipe?

Cutting steel pipes can be done using tools such as pliers, hand saws, chainsaws, or cutting machines, but attention should be paid to safety and protecting the cutting edges.

12.3 Drilling Holes In Steel Pipe

When drilling, a drill bit or drilling machine can be used to select the appropriate diameter and depth as needed.

12.4 Steel Pipe Threading

Steel pipe threading is the process of using threading tools to form threads on the inside or outside of a steel pipe for connection with threaded fittings.

12.5 Steel Pipe Expanding Process

The steel pipe expansion process utilizes specialized tools and techniques to expand one end of the steel pipe into a cylindrical shape through an expansion joint or expansion, in order to connect with other steel pipes.

12.6 Pipe Bending

The steel pipe bending process utilizes a pipe bending machine or cold bending process to bend the steel pipe into specific angles and shapes as needed.

12.7 Steel Pipe Heat Treatment Process

The heat treatment process of steel pipes includes heating and cooling processes, aiming to change the physical and chemical properties of steel pipes to improve their hardness, strength, and corrosion resistance. The main methods include normalizing, quenching, and other methods.

12.8 Steel Pipe Surface Treatment

The surface treatment of steel pipes can be carried out by methods such as hot-dip galvanizing, spraying, polishing, etc., to improve the corrosion resistance and appearance quality of the steel pipes.

These methods and processes are very important for the manufacturing and application of steel pipes, and suitable methods and tools can be selected according to specific needs.

13.Steel Pipe Testing

Steel pipe testing is an important process to ensure the quality and integrity of steel pipes used in various industries such as oil and gas, water supply, construction, and manufacturing. The common methods for detecting steel pipes are as follows:

13.1. Appearance Inspection

This includes checking the dimensions of the pipeline, such as diameter, wall thickness, and length, as well as checking for any visual or surface defects that may affect its performance or structural integrity.

13.2. Destructive Testing

Place the steel pipe sample under extreme conditions to evaluate its mechanical properties and behavior under stress. This may include tests such as tensile testing, which involves pulling the pipeline until it fractures to determine its ultimate tensile strength and yield strength. It can also include impact testing to evaluate the pipeline's ability to absorb impacts and withstand sudden loads. Bending test, flattening test, chemical composition detection, and so on.

13.3. Non-Destructive Testing(NDT)

Non destructive testing technology is also widely used in steel pipe testing. These technologies allow for evaluating the integrity of pipelines without causing any damage to the materials. Common non-destructive testing includes:

Ultrasonic testing: where high-frequency sound waves are used to detect defects or irregularities in pipeline structures;

Magnetic particle testing:it is using magnetic fields and particles to identify surface or near surface defects;

Radiographic testing: where X-rays or gamma rays are used to check for internal defects in pipelines.

13.4. Corrosion Detection

Corrosion testing is another important aspect of steel pipe testing. Corrosion can seriously affect the performance and lifespan of steel pipes, especially in corrosive environments. Corrosion testing involves exposing pipelines to various corrosive agents or conditions to evaluate their corrosion resistance and evaluate the effectiveness of protective coatings or treatments. Common methods include salt spray detection, etc.

13.5. Water Pressure Testing

In this experiment, the pipeline is filled with water or other suitable fluid and pressurized to a certain level. The purpose of this experiment is to evaluate the ability of pipelines to withstand internal pressure without any leakage or failure. The test pressure is usually specified by industry standards or project requirements.

In summary, steel pipe inspection plays a crucial role in the quality control and assurance of steel pipes. By conducting various tests and inspections, manufacturers and end-users can ensure that pipelines meet the necessary standards and specifications for safe and reliable use in different applications.

14.How To Treat Steel Pipe To Prevent It From Rusting?

Steel pipe is a commonly used industrial pipeline material, which has advantages such as high strength and corrosion resistance, and is widely used in many fields. However, during use, steel pipes are prone to oxidation and corrosion, resulting in surface rust and affecting the sealing and safety performance of the pipeline. Therefore, rust prevention measures for steel pipes are very important. This article will introduce several methods for rust prevention of steel pipes.

14.1.Oiling

Oil coating aims to prevent rust on steel pipes. Oil products should not deteriorate within one year under dry and dry storage conditions at room temperature; It can be easily removed from the alkaline oiling agent treated before painting. Steel pipe oil coating is often used for short-term rust prevention treatment of steel pipes.

14.2.Spray-painting

Spray painting method is a simple and effective rust prevention method for steel pipes and steel. It is achieved by spraying specific chemical coatings on the surface of steel pipes to form a uniform protective layer, thereby preventing oxidation and corrosion. There are many types of coatings for spray painting, and corresponding coatings should be selected according to different usage environments and requirements. Common methods include spraying black paint, such as black square pipes; Spray red paint, such as fire steel pipes.

14.3.Hot Dip Galvanized Method

Hot dip galvanizing is an environmentally friendly method for preventing rust in steel pipes. It is to first remove oil and rust from the surface of the steel pipe, then preheat it, and finally immerse it in melted polymer powder to attach the powder to the surface of the steel pipe at high temperature, forming a uniform protective layer. Hot dip plastic steel pipes have high corrosion resistance and mechanical strength, and are suitable for pipeline systems in industries such as chemical, textile, food, beverage, and pharmaceutical.

14.4.Anodic protection

Anodic protection is a widely used rust prevention method for steel pipes, which forms an electrochemical protective layer on the surface of the steel pipe to prevent oxidation and corrosion. Anodic protection coatings are usually composed of metal sheets such as zinc, aluminum, magnesium, and tin. After these metal sheets come into contact with the surface of the steel pipe, they form an electrochemical reaction protection layer with a high potential to protect the steel pipe from oxidation and corrosion.

15.Steel Pipe Lifespan

The service life of steel pipes generally depends on their purpose and material quality. In general, under normal usage, the lifespan of both production line pipelines and building materials is between 20-50 years. However, more attention should be paid to cold and hot water pipelines and gas pipelines, which have a lifespan between 10 and 30 years. In addition, steel pipes may suffer from various corrosion and damage during use, which is also an important reason for shortening their lifespan.

15.1 Factors Affecting The Service Life Of Steel Pipes

The service life of steel pipes is influenced by various factors, mainly including the following aspects:

15.1.1. Service environment:

If the steel pipe is exposed to harsh environments such as humidity, high temperature, and corrosion for a long time, its service life will be greatly shortened.

15.1.2. Quality:

The quality of steel pipes is directly related to their service life. Poor quality steel pipes are prone to deformation, embrittlement, damage, etc.

15.1.3. Installation method

If reasonable measures are not taken during the installation of the steel pipe, such as excessive bending, improper splicing, etc., it will increase the fatigue damage of the steel pipe, leading to a shortened service life.

Under the influence of the above factors, the service life of ordinary welded steel pipes is about 20 years, while some special anti-corrosion and anti-corrosion steel pipes can be used for 40-50 years.

16.Get The Right Pipes For Your Project Now

Choosing the appropriate type and specification of steel pipes is crucial for ensuring the quality and reliability of the project. Here are some tips for selecting steel pipes:

16.1. Determine The Project Requirements.

First of all, it is necessary to define the specific requirements of the project, such as the environment of use, the pressure and temperature range. These requirements will help to determine the required pipe materials and specifications.

16.2. Material Selection:

Select appropriate steel pipe materials based on project requirements and budget constraints. Common steel pipe materials include carbon steel, stainless steel, alloy steel, etc. Carbon steel is commonly used in general engineering and construction applications, while stainless steel is suitable for environments with high corrosion resistance requirements.

16.3. Specification Selection

Select appropriate steel pipe specifications based on project requirements and design parameters, including outer diameter, wall thickness, and length. The selection of specifications should take into account the required strength, bearing capacity, and adaptability.

16.4. Standard Compliance:

Ensure that the selected steel pipes comply with corresponding international or industry standards, such as ASTM, DIN, ISO, etc. These standards specify the material, manufacturing process, and performance requirements of steel pipes to ensure their quality and reliability.

16.5. Corrosion Resistance:

If the project requires the use of steel pipes in corrosive environments, it is crucial to choose materials and coatings with good corrosion resistance.

16.6. Costing

When selecting steel pipes, it is necessary to comprehensively consider cost efficiency. Evaluate factors such as prices, maintenance costs, and lifespan of different materials and specifications to find the most suitable choice.

16.7. Consultation With Professionals

If you are unsure about the selection of steel pipes or need professional advice, it is recommended to consult engineers or professionals from Yuantai Derun. They can provide more specific guidance based on project requirements and specific circumstances.

Summary

Sample Content