Metallographic analysis and comparison of ferrite, cementite, pearlite, austenite, martensite, bainite, ledeburite, and Widmannstatten structure

Metallography is an important indicator for measuring metal materials. Today, the editor will bring you some common metallographic analysis and performance comparison of ferrite, cementite, pearlite, austenite, martensite, bainite, ledeburite, and Widmannstatten structure.

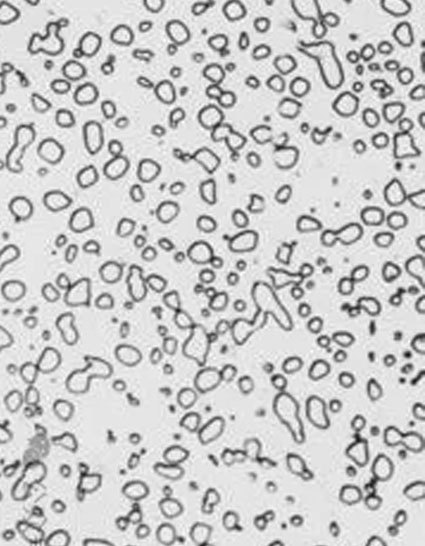

1. Ferrite (F, α - Fe)

Definition: Ferrite is a interstitial solid solution formed by a small amount of carbon and alloy elements dissolved in a body centered cubic lattice α - Fe.

Features: Microscopic features, presenting as bright white block like, layered, granular, network like, etc.

Property: Its strength and hardness are the lowest among steel structures, about 250-300MPa and 80-100HB, but it has good plasticity and toughness.

2. Carbide (Fe3C)

Definition: Carbide is a metal compound with a complex lattice formed by excess iron and carbon in iron-carbon alloys when the carbon content exceeds the solubility limit of carbon in iron.

Features:

Microscopic characteristics: It is white in color and has various forms, such as sheet-like (needle like), granular, network like, semi network like, etc.

Property: High hardness (about 745-800 HB), high brittleness, and almost zero plasticity and impact toughness.

Mesh cementite 200x

Needle shaped cementite (Weinstein structure) 200x

Granular cementite 500 x

3. Pearlite (P)

Definition: Pearlite is a product of eutectoid reaction during the cooling process of austenite, and it is also a mechanical mixture composed of ferrite and cementite.

Features:

Microscopic characteristics: It is a layered pearlite with a decreasing interlayer spacing as undercooling increases.

Property: Its strength and hardness are significantly higher than ferrite, but its plasticity and toughness are worse than ferrite and much better than cementite.

Flake pearlite 200 x

T8 annealed state 500 x

Spherical pearlite 500x

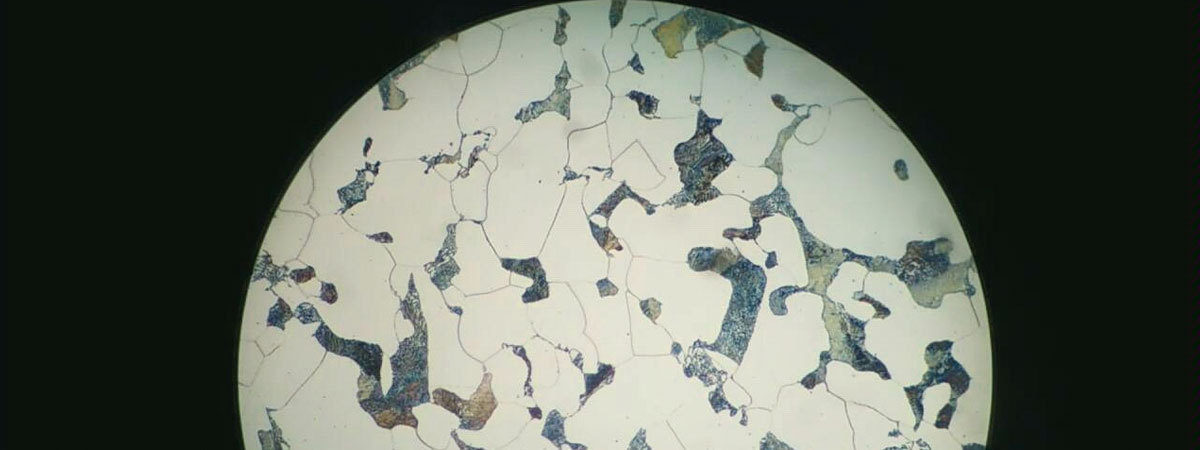

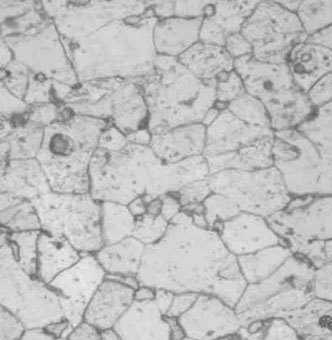

4. Austenite (A)

Definition: Austenite is a interstitial solid solution formed by carbon and alloying elements in a face centered cubic lattice of γ - Fe.

Features:

Organizational characteristics: There are twin or slip lines in austenitic steel, and the grain boundaries are relatively straight.

Some quenched steels can retain some austenite to room temperature, which is referred to as residual austenite. Austenite is generally composed of equiaxed polygonal grains, with twinning within the grains. At the end of the heating transformation, the austenite grains are relatively small and the grain boundaries are irregularly curved. After a period of heating or insulation, the grains will gradually grow and the grain boundaries can tend to straighten.

Property: It has high toughness and plasticity (δ 5 is 40-60%), and appropriate strength and hardness (about 170-200HB).

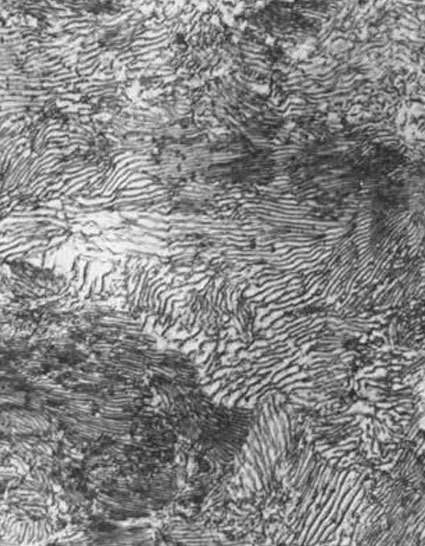

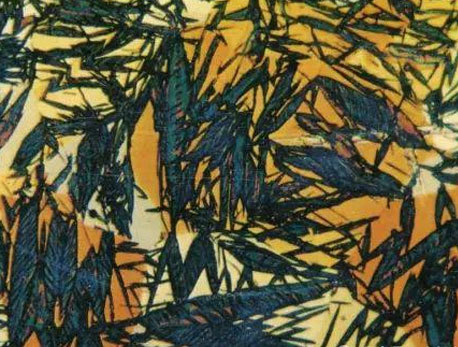

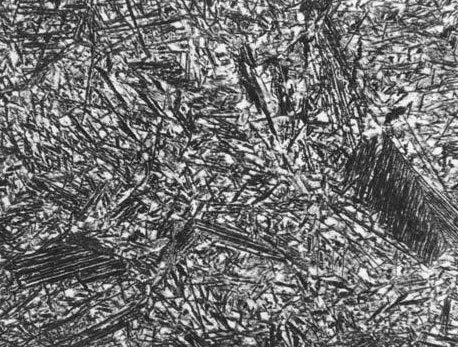

5. Martensite (M)

Definition: Martensite is a supersaturated solid solution of carbon in alpha Fe, or a supersaturated solid solution of carbon and alloying elements in alpha Fe in alloy steel.

Features:

Microstructure characteristics: mainly needle like or lath like.

Type: Flat noodles martensite is martensite existing in low-carbon structural steel; Needle like martensite is a type of martensite present in high carbon steel.

Lath-martensite

Acicular-martensite

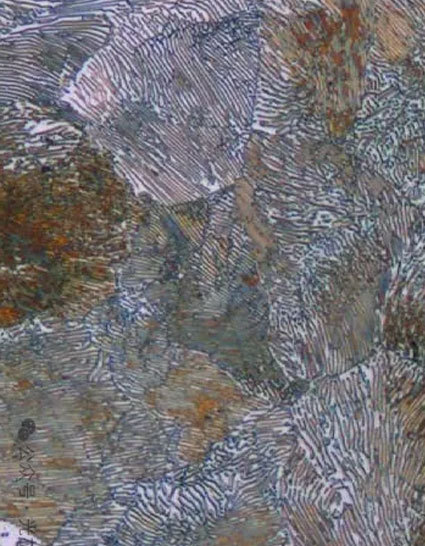

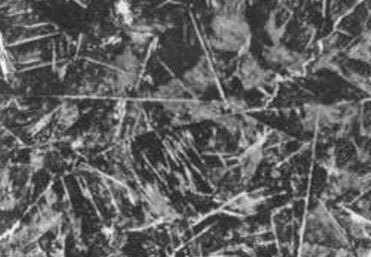

6. Bainite

Definition: Bainite is a transformation product formed by the combination of shear transformation and short-range diffusion when austenite is undercooled to a temperature range below the pearlite transformation temperature and above the martensite transformation temperature.

Upper bainite 500x

Upper bainite: formed at 500 ℃~350 ℃, characterized by roughly parallel feathery ferrite with short rod-shaped carbides between the ferrite bars.

Lower bainite

Lower bainite: formed at 350 ℃~230 ℃, characterized by needle like morphology, and the arrangement of cementite at an angle of 55 °~60 ° with the long axis of the needle. Hardened martensite is more susceptible to corrosion and is highly similar to tempered martensite. It is extremely difficult to distinguish under light microscopy and easily distinguishable under electron microscopy; Carbides precipitate in the needle shaped ferrite. The lower bainite does not contain twinning and has more dislocations.

Granular bainite 200x

Granular bainite: a polygonal ferrite with many irregular small island like structures inside. Granular carbides are distributed on the ferrite matrix (the small island structure was originally carbon rich austenite, which decomposed into ferrite and carbides during cooling, or transformed into martensite or still carbon rich austenite particles).

7.Ledeburite

Features:

Structural composition:

At room temperature, ledeburite is a mixture of pearlite, cementite, and eutectic cementite.

Composed of austenite and cementite formed by eutectic transformation of liquid iron carbon alloy, with a carbon content of ω c=4.3%.

At high temperatures, eutectic carbides are distributed in a fishbone or network shape at grain boundaries. After thermal processing and crushing, they become blocky and distributed in a chain like manner along the rolling direction.

Temperature impact:

When the temperature is above 727 ℃, the martensite is composed of austenite and cementite, represented by the symbol Ld.

When the temperature is below 727 ℃, the martensite is composed of pearlite and cementite, represented by the symbol Ld ', and is called abnormal martensite.

Morphological changes:

As the temperature decreases, the total carbon content in the martensite remains unchanged, but the proportion of austenite and cementite in the composition changes.

Performance:

Hardness and plasticity:

The matrix of Leinite is a hard and brittle cementite, therefore its hardness is high and plasticity is poor.

Resilience:

Due to the influence of high alloy composition, ledeburite has low toughness and high deformation resistance.

Thermal conductivity:

The thermal conductivity of martensite is poor, and the microstructure stress is high during the cooling process, so the forging of martensite steel is a difficulty in forging.

Ledeburite Metallographic Diagram

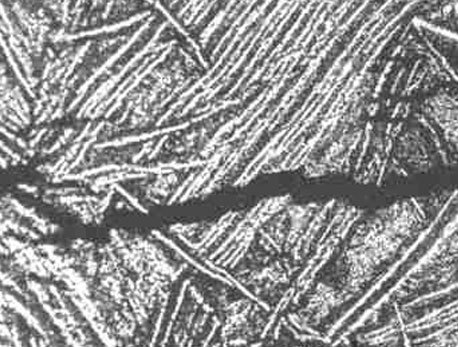

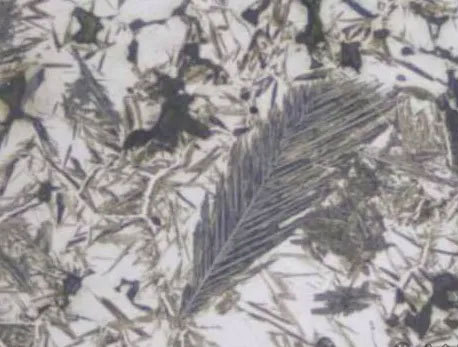

8.Widmannstatten structure

Definition

Weinstein structure is a special type of superheat structure formed in the overheated zone of welding due to the very coarse growth of austenite grains at a fast cooling rate.

Formation: This type of structure is usually formed when the austenite grains are relatively coarse and the cooling rate is appropriate. It manifests as the formation of many parallel ferrite (cementite) needles within a coarse austenite grain, and the remaining austenite between the ferrite needles eventually transforms into pearlite.

Organizational characteristics

Morphology: The ferrite or cementite in the Weiss organization is distributed directionally on the pearlite matrix, usually in a feather like, equilateral triangular, perpendicular to each other, or mixed form of ferrite.

Composition: The Weinstein structure is mainly composed of ferrite (cementite) needle plates and pearlite.

Cause of occurrence

Material: Overheated medium carbon steel or low carbon steel is prone to the formation of Weinstein structure at an appropriate cooling rate.

Process: Overheating and rapid cooling during the welding process are the main reasons for the formation of the Weinstein structure.

Performance

Mechanical properties: The presence of Weinstein structure usually leads to a decrease in the mechanical properties of steel, especially a significant decrease in impact toughness and plasticity, increasing the brittle transition temperature of steel and making it prone to brittle fracture.

Brittleness: The Weinstein structure increases the transition temperature between toughness and brittleness of steel, increasing its brittleness.

Widmannstatten structure cementite 200x

Coarse crystalline Weiss tissue 200x

Final Words:

Metallic materials in different metallurgical conditions, their performance, characteristics have various different. Today, I summarize the definition, characteristics, and properties of ferrite, carburite, pearlite, austenite, martensite, bainite, leucite, and Weil's organization, I hope you have some help, for more information, please contact our account manager.