How To Understand Steel Gauges?

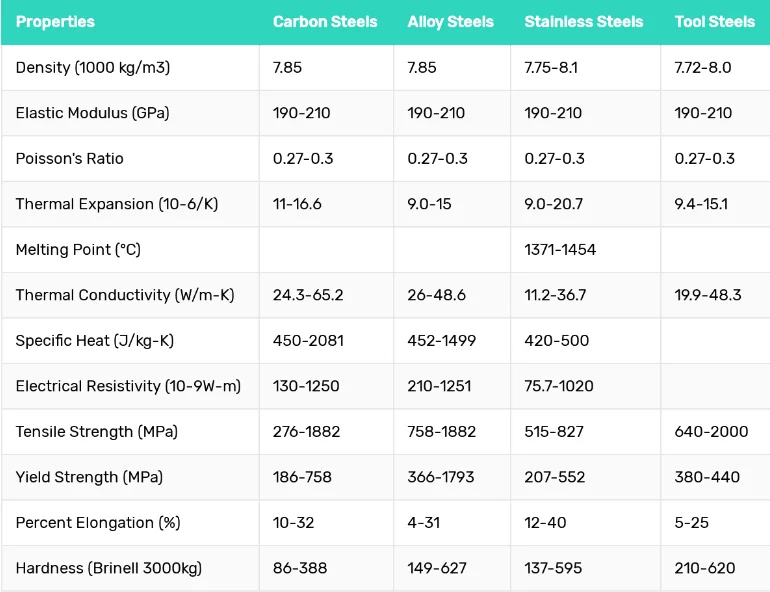

Overview

Steel gauge is a common metal material measurement value in steel, and as a steel user, these are knowledge that you must understand. This article provides a detailed introduction to the content of steel gauges from multiple aspects such as their definition, history, and steel gauge chart. I believe that after reading it, you will have a comprehensive understanding of steel gauges.

1.What Is A Steel Gauge?

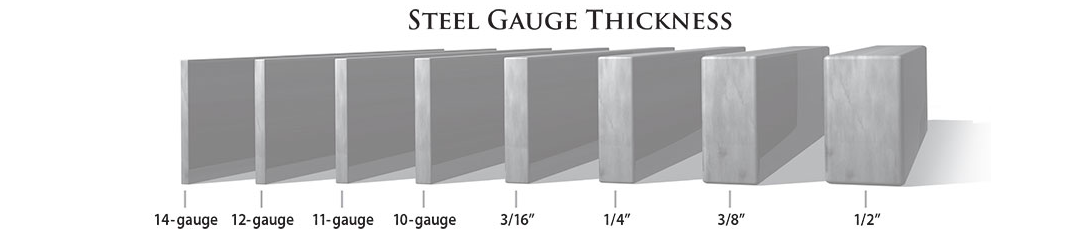

Steel gauge is a standardized method for measuring and distinguishing steel plate products, such as sheet metal, coil material,wire and pipe etc. Surprisingly, as the number of steel gauges increases, the thickness of the steel actually decreases. For example, 10 gauge steel is thicker than 12 gauge steel. The thickness of the steel plate varies from 3GA (thickest) to 38GA (thinnest). Note that "gauge" is sometimes spelled as "gage" or "GA" as an abbreviation.

2.History Of Steel Gauge

2.1 Where Does The Measurement Come From?

Where do the measurements come from? You must also be very interested to know.

Steel gauges have their origins in the wire industry during the industrial revolution in England, when there was no common unit for thickness. The size of the wire gauge number was determined by the wire drawing process and the nature of the iron. Workers drawing metal wire would calculate the diameter based on the number of draws, which was the gauge (so the larger the gauge, the thinner the material). The more times the wire is drawn, the thinner the wire becomes, and this inverse relationship continues with sheet and other non-metallic wire products.

2.2 Why Are They Used Instead Of Inches Or Millimeters?

You can also find some answers to this question from the description in the previous paragraph. Because during the industrial revolution in England, there was no common unit for thickness. That's why which workers who drew metal wires calculated the diameter based on the number of draws. And the use of inches and millimeters was only slowly and widely used until the 19th century, when the steel gauge was gradually replaced by inches or millimeters. Currently, the steel gauge is still used in some areas.

3.Picking The Right Steel Gauge

For objects that require rigidity and edges, you can use thicker (or lower specification) steel. However, for some objects that require flexibility or flexibility, you need to use thinner (or higher specification) steel to adapt to this situation.

4.How To Read A Steel Gauge Thickness Chart?

In practice, in most cases, we need to read the steel gauge thickness chart. Small through the organization, deliberately the commonly used metal steel gauge thickness table summarized down, next, take you to see how these tables are read, as well as what are the relevant content in the table.

4.1 Sheet Metal Gauge Chart

First, take a look at sheet metal gauge chart. Ferrous metals use a different metering system than non-ferrous metals like copper, which are measured in ounces per square foot.

4.2 Carbon Steel/Mild Steel Gauge Chart

4.3 Galvanized Steel Gauge Chart

4.4 Stainless Steel Gauge Chart

4.5 Aluminum Gauge Chart

Gauges are used to represent the thickness of metal plates. It is not standard or metric, and its value is independent of this measurement system. A thickness gauge can be used to determine the actual thickness of a metal plate, in inches or millimeters. Different metal types, even the same steel gauges, have different thicknesses. For example, the thickness of 18 steel gauge is 0.0478 inches or 1.214 millimeters. But the thickness of the 18 aluminum gauge is 0.0403 inches.

4.6 Brass Gauge Charts

4.7 Copper Gauge Chart

4.8 Zinc Gauge Chart

|

Gauge

|

Thickness

|

Weight Per Area

|

||

|

in

|

mm |

lb/ft²

|

kg/m²

|

|

|

28

|

1

|

25.4 |

37.152

|

181.392

|

|

27

|

0.5

|

12.7 |

18.576

|

90.696

|

26 | 0.375 | 9.525 | 13.932 | 68.022 |

25 | 0.25 | 6.35 | 9.288 | 45.348 |

24 | 0.125 | 3.175 | 4.644 | 22.674 |

23 | 0.1 | 2.54 | 3.715 | 18.139 |

22 | 0.09 | 2.286 | 3.344 | 16.325 |

21 | 0.08 | 2.032 | 2.972 | 14.511 |

20 | 0.07 | 1.778 | 2.601 | 12.697 |

19 | 0.06 | 1.524 | 2.229 | 10.884 |

18 | 0.055 | 1.397 | 2.043 | 9.977 |

17 | 0.05 | 1.27 | 1.858 | 9.07 |

16 | 0.045 | 1.143 | 1.672 | 8.163 |

15 | 0.04 | 1.016 | 1.486 | 7.256 |

14 | 0.036 | 0.914 | 1.337 | 6.53 |

13 | 0.032 | 0.813 | 1.189 | 5.805 |

12 | 0.028 | 0.711 | 1.04 | 5.079 |

11 | 0.024 | 0.61 | 0.892 | 4.353 |

10 | 0.02 | 0.508 | 0.743 | 3.628 |

9 | 0.018 | 0.457 | 0.669 | 3.265 |

8 | 0.016 | 0.406 | 0.594 | 2.902 |

7 | 0.014 | 0.356 | 0.52 | 2.539 |

6 | 0.012 | 0.305 | 0.446 | 2.177 |

5 | 0.01 | 0.254 | 0.372 | 1.814 |

4 | 0.008 | 0.203 | 0.297 | 1.451 |

3 | 0.006 | 0.152 | 0.223 | 1.088 |

2 | 0.004 | 0.102 | 0.149 | 0.726 |

1 | 0.002 | 0.051 | 0.074 | 0.363 |

4.9 Birmingham Gauge Chart

|

Gauge

|

Thickness

|

|

|

inch

|

mm

|

|

|

0000000

|

0.6666

|

16.932

|

|

000000

|

0.6250

|

15.875

|

00000 | 0.5883 | 14.943 |

0000 | 0.5416 | 13.757 |

000 | 0.5000 | 12.700 |

00 | 0.4452 | 11.308 |

0 | 0.3964 | 10.069 |

1 | 0.3532 | 8.971 |

2 | 0.3147 | 7.993 |

3 | 0.2804 | 7.122 |

4 | 0.2500 | 6.350 |

5 | 0.2225 | 5.652 |

6 | 0.1981 | 5.032 |

7 | 0.1764 | 4.481 |

8 | 0.1570 | 3.988 |

9 | 0.1398 | 3.551 |

10 | 0.1250 | 3.175 |

11 | 0.1113 | 2.827 |

12 | 0.0991 | 2.517 |

13 | 0.0882 | 2.240 |

14 | 0.0785 | 1.994 |

15 | 0.0699 | 1.775 |

16 | 0.0625 | 1.588 |

17 | 0.0556 | 1.412 |

18 | 0.0495 | 1.257 |

19 | 0.0440 | 1.118 |

20 | 0.0392 | 0.996 |

21 | 0.0349 | 0.886 |

22 | 0.0312 | 0.792 |

23 | 0.0278 | 0.706 |

24 | 0.0247 | 0.627 |

25 | 0.0220 | 0.559 |

26 | 0.0196 | 0.498 |

27 | 0.0174 | 0.442 |

28 | 0.0156 | 0.396 |

29 | 0.0139 | 0.353 |

30 | 0.0123 | 0.312 |

31 | 0.0110 | 0.279 |

32 | 0.0098 | 0.249 |

33 | 0.0087 | 0.221 |

34 | 0.0077 | 0.196 |

35 | 0.0069 | 0.175 |

36 | 0.0061 | 0.155 |

37 | 0.0054 | 0.137 |

38 | 0.0048 | 0.122 |

39 | 0.0043 | 0.109 |

40 | 0.0038 | 0.097 |

41 | 0.0034 | 0.086 |

42 | 0.0030 | 0.076 |

43 | 0.0027 | 0.069 |

44 | 0.0024 | 0.061 |

45 | 0.0021 | 0.053 |

46 | 0.0019 | 0.048 |

47 | 0.0017 | 0.043 |

48 | 0.0016 | 0.041 |

49 | 0.0013 | 0.033 |

50 | 0.0012 | 0.030 |

51 | 0.0011 | 0.027 |

52 | 0.0010 | 0.024 |

5.Summary

Steel gauge is important value for steel or metal user.The larger the steel gauge value, the thinner the metal thickness. You must not consider this matter according to conventional linear measurement thinking. If you still have any questions,please contact us now!

FAQ

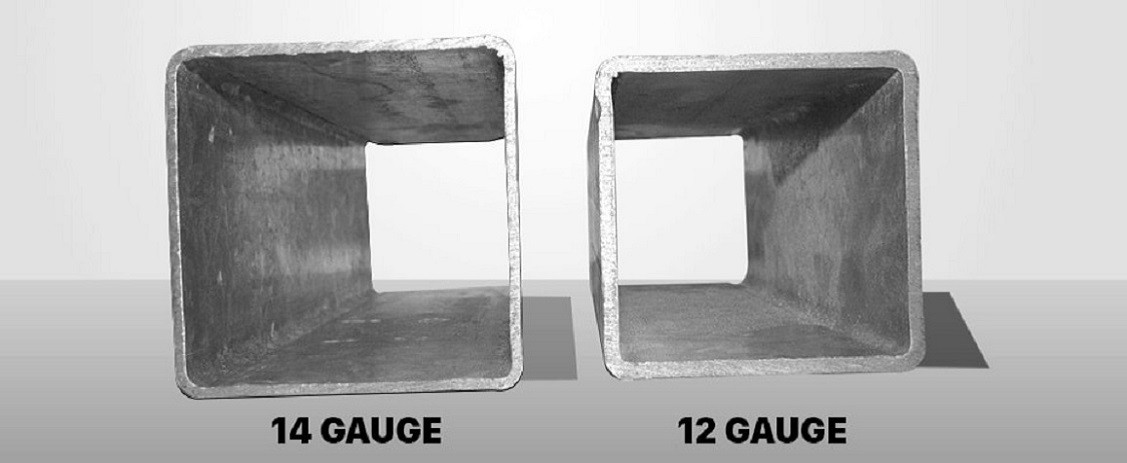

1.How thick is 12 gauge steel?

12 gauge steel means that the thickness:

Approximate thickness in fractions of 7/64 inches 。

Approximate thickness 2.778125 mm.

2.How thick is 20 gauge steel?

20 gauge steel means that the thickness:

Approximate thickness in fractions of 3/80 inches 。

Approximate thickness 0.9525 mm.

3.Which is thicker 10 or 11 gauge steel?

10 gauge steel is thicker than 11 guage steel.

4.What is thicker 14 or 16 gauge steel?

14 gauge steel is thicker than 16 gauge steel.

5.What is better 12 or 14 gauge steel?

In the gauge system the higher the number the thinner the steel. As an example, 12 gauge steel is thicker and stronger than 14 gauge steel.

6.Is 10 gauge steel thick?

For sheet metal, a retrogressive scale (higher numbers mean lower thickness) that starts with 10 gauge representing a thickness of 3.416 millimeters or 0.1345 inches. ... For example, a 12 gauge sheet is 2.732 millimeters thick, and a 13 gauge sheet is 2.391 millimeters thick.

7.Is 10 gauge steel strong?

A door made from 10-gauge (. 135) steel is over twice as strong as one made from 12-gauge (. 106) steel even though it is only . 029 thicker (see Steel Strength Chart).

8.What is thicker 12 or 13 gauge steel?

12 gauge steel is thicker than 13 gauge steel.