Carbon Steel Pipe Basics You Should Know

Carbon Steel Pipe Basics You Should Know

Introduction:

In today's industrial world, carbon steel pipes play a crucial role in construction, petrochemicals, and power industries. Their unique advantages make them indispensable. This article delves into the type,characteristics, applications, and future trends of carbon steel pipes, aiming to provide readers with a comprehensive understanding.

1. What Is Carbon Steel Pipe?

Carbon steel pipe is a metal pipe made of carbon steel. Carbon Steel Pipe is also known as CS Pipe.Carbon steel is a type of iron carbon alloy material. Carbon steel pipes have excellent strength and pressure resistance, and are used in fluid transportation, structural support, mechanical manufacturing, etc

2. Carbon Steel Pipe Types

Carbon steel pipes can be classified from multiple dimensions. Below, let's understand the types, advantages and disadvantages, and application scenarios of carbon steel pipes.

2.1 According To Production Process:

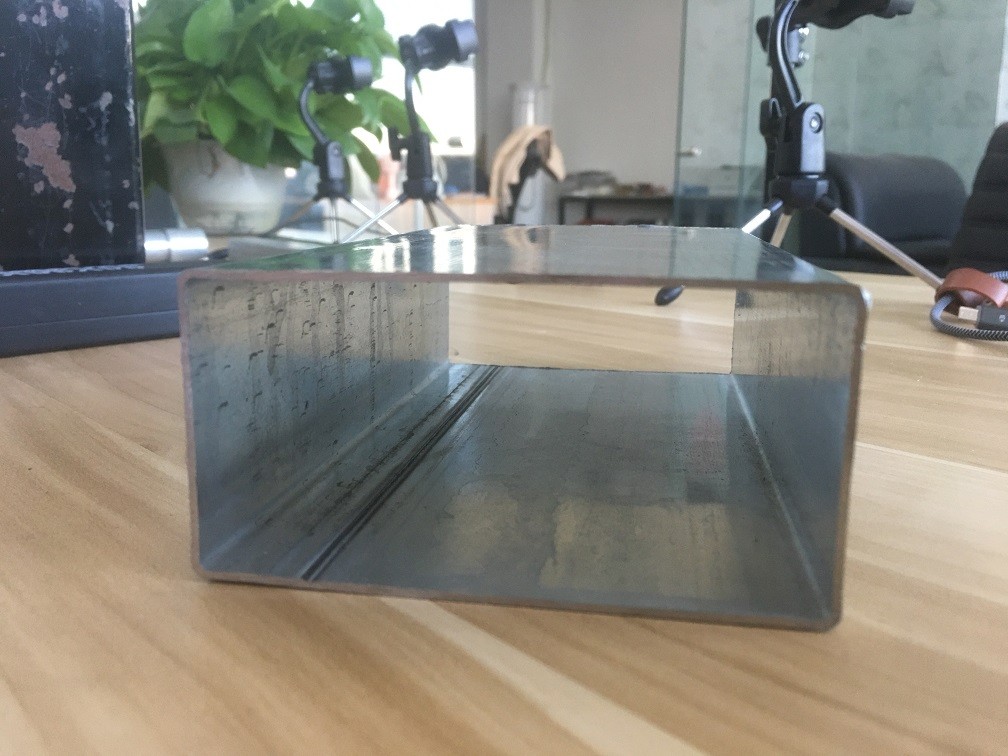

Firstly, carbon steel pipes are distinguished according to the production process, which can be divided into welded steel pipes and seamless steel pipes. Welded steel pipes are manufactured by processes such as uncoiling, forming, and high-frequency welding of steel coils. Seamless steel pipes are made by piercing and rolling steel bars. I won't elaborate on it here.

It is also easy to distinguish between welded steel pipes and seamless steel pipes, and we can usually distinguish them with the naked eye, because welded steel pipes usually have a weld seam on the pipe body, while seamless steel pipes do not have any weld seams on the pipe body.

2.2 According To Shape:

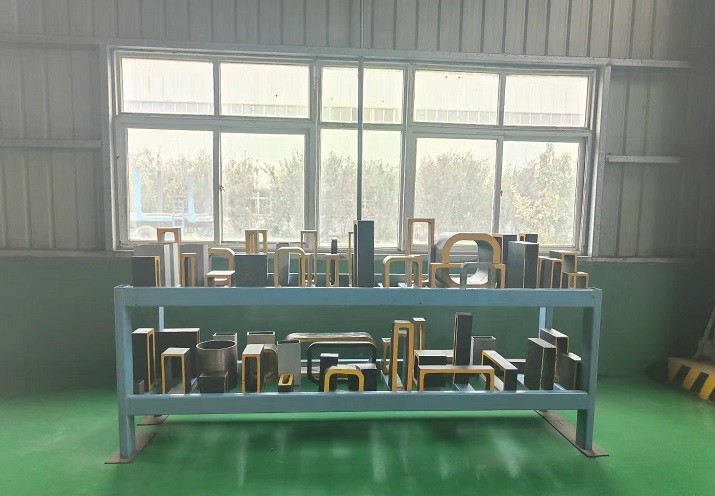

If classified by shape, carbon steel pipes include circular carbon steel pipes, square carbon steel pipes, rectangular carbon steel pipes, and special-shaped carbon steel pipes. Circular pipes are mainly used for fluid transportation applications such as oil and natural gas. Square steel pipes, rectangular pipes, and irregular pipes are commonly used in the application scenarios of building structures and mechanical structures.

2.3 According To Carbon Content:

Carbon steel pipes can be divided into low-carbon steel pipes,medium carbon steel pipes and high carbon steel pipes according to their carbon content.

Now let me introduce to you.

Firstly, let's take a look at low-carbon steel pipes. Low carbon steel pipe, as the name suggests, refers to steel pipes with lower carbon content. Generally speaking, the carbon content of low-carbon steel pipes is about 0.04%~0.30%. The advantage of this type of steel pipe lies in its excellent plasticity and toughness. Due to its low carbon content, low-carbon steel pipes are less prone to brittle fracture under pressure, thus having a higher safety factor. In addition, due to its excellent plasticity, low-carbon steel pipes are easy to process and weld, making them suitable for various complex forming and connecting processes. Low carbon steel pipes are an ideal choice in areas such as construction, petrochemicals, etc. that require high pressure but also prevent brittle fracture.

Secondly, usually, we refer to carbon steel pipes with a carbon content range of 0.30% to 0.60% as medium carbon steel pipes.Medium carbon steel has high strength and hardness, but low plasticity and toughness. Commonly used medium carbon steel includes 45 # steel, 40Cr, etc.

Finaly, let's explore high carbon steel pipes. High carbon steel pipe refers to a steel pipe with a high carbon content, which is usually around 0.60% ~ 2.00%. Compared with low-carbon steel pipes, high carbon steel pipes have higher strength and hardness, as well as superior wear and corrosion resistance. This gives high carbon steel pipes irreplaceable advantages in certain specific fields. For example, in industries with severe wear such as mines and coal, high carbon steel pipes can provide better wear resistance and extend the service life of equipment. In addition, high carbon steel pipes also have good corrosion resistance and are suitable for use in acidic or alkaline environments. However, due to its high carbon content, the welding performance of high carbon steel pipes is relatively poor, requiring special treatment and processing.

2.4 According To Surface Treatment:

Carbon steel pipes can be classified according to surface treatment, including black carbon steel pipes, pre galvanized carbon steel pipes, hot-dip galvanized carbon steel pipes, zinc aluminum magnesium coated carbon steel pipes, anti-corrosion carbon steel pipes, etc.

Today, I will provide a detailed explanation of five different surface treated carbon steel pipes from the perspective of professional technicians: black carbon steel pipes, pre galvanized carbon steel pipes, hot-dip galvanized carbon steel pipes, zinc aluminum magnesium coated carbon steel pipes, and anti-corrosion carbon steel pipes. These different surface treatment methods endow carbon steel pipes with different characteristics and uses.

Black carbon steel pipe: The surface of this steel pipe has not undergone any special treatment, presenting a natural black color. Its advantage lies in its low cost and suitability for occasions with low anti-corrosion requirements. But due to the lack of coating protection, it is prone to corrosion and oxidation.

Pre galvanized carbon steel pipe: During the production process, a thin layer of zinc is pre coated on the outer wall of the steel pipe. This provides a certain degree of corrosion resistance for steel pipes, especially in humid environments. However, compared to hot-dip galvanizing, its anti-corrosion performance is weaker.

Hot dip galvanized carbon steel pipe: Hot-dip galvanized steel pipe is a type of steel pipe where black carbon steel pipe is immersed in a high-temperature molten zinc bath, forming a thick layer of galvanized coating on the outer wall of the steel pipe. This imparts excellent anti-corrosion properties to the hot-dip galvanized steel pipe, making it resistant to various harsh environments. It finds widespread applications in outdoor and chemical industries.

Zinc aluminum magnesium coated carbon steel pipe: This is a new coating technology that adds aluminum and magnesium elements on the basis of galvanizing. Compared with traditional hot-dip galvanizing, zinc aluminum magnesium coating has better anti-corrosion performance and can better resist corrosion and oxidation. It is mainly used in situations with very high anti-corrosion requirements, such as marine engineering, petrochemical industry, etc.

Anti corrosion carbon steel pipe: The outer surface of this type of steel pipe has undergone special anti-corrosion treatment, such as spraying, painting, etc., which can provide strong anti-corrosion ability. However, compared to galvanized steel pipes, their anti-corrosion performance may be weaker and have certain requirements for the usage environment.

The appropriate surface treatment method for carbon steel pipes needs to be determined based on actual application scenarios. For example, in humid or highly corrosive environments, hot-dip galvanized or zinc aluminum magnesium coated steel pipes are a better choice; In situations where anti-corrosion requirements are not high, black or pre galvanized steel pipes are more economical and practical.

By understanding these carbon steel pipes with different surface treatments, new users can better choose products that suit them and ensure the smooth progress of engineering or projects.

2.5 According To Welds:

Carbon steel pipes can be classified into LSAW steel pipes with straight seam double-sided submerged arc welding, spiral welded steel pipes, ERW steel pipes with resistance high-frequency welding, and so on.

Today, I will provide a detailed explanation of three different welding methods for carbon steel pipes from the perspective of professional technicians: LSAW steel pipe, spiral welded steel pipe, and ERW resistance high-frequency welded carbon steel pipe. These different welding methods have a significant impact on the performance and application of steel pipes.

Features: Double sided welding is achieved by burning the arc under the flux layer, with high strength, uniform thickness, and stable weld quality.

Advantages: High production efficiency, weld strength comparable to the base material, suitable for large-scale production.

Application: Widely used in the transportation of media such as oil, natural gas, water, and the manufacturing of structural components.

Features: Adopting continuous spiral curling forming method, the steel pipe section is circular or elliptical with joints.

Advantages: It has good flexibility, small bending radius, and is easy to install; Compared to straight seam steel pipes, spiral welded pipes can be manufactured using thinner plates.

Application: Suitable for long-distance transportation, such as water and gas pipeline systems.

Features: Using the skin effect of high-frequency current, heat the edge of the strip steel to a molten state for welding.

Advantages: Simple process, high efficiency, low cost, and stable weld quality; No use of flux or shielding gas, no environmental pollution.

Application: Widely used in the transportation of media such as oil, natural gas, water, and the manufacturing of structural components.

The choice of appropriate welding method depends on the actual application requirements. For example, for situations that require high strength and uniform thickness, straight seam double-sided submerged arc welding of carbon steel pipes is an ideal choice; For situations that require good flexibility and small bending radius, spiral submerged arc welding of carbon steel pipes is more suitable; ERW resistance high-frequency welding of carbon steel pipes is widely used in various medium transportation and structural component manufacturing due to its advantages of simple process and low cost.

2.6 According To Heat Treatment:

Carbon steel pipes can be classified according to heat treatment methods into hot-rolled carbon steel pipes, cold-rolled carbon steel pipes, and cold-drawn carbon steel pipes.

Today, I will provide a detailed explanation of the three heat treatment processes for carbon steel pipes from the perspective of professional technicians: hot rolling, cold rolling, and cold drawing. These different heat treatment methods have a significant impact on the performance and application of carbon steel pipes.

A.Hot rolled carbon steel pipes:

Features: Rolling steel pipes at high temperatures to obtain the desired shape and size.

Advantages: Relatively low cost, suitable for large-scale production.

Application: Suitable for structural components and conveying pipelines, especially in situations where strength requirements are not high.

Features: Rolling steel pipes at room temperature can improve their accuracy and surface smoothness.

Advantages: It has better dimensional stability and surface quality, suitable for situations with high precision requirements.

Application: Widely used in fields such as automobiles, home appliances, and construction.

C.Cold drawn carbon steel pipes:

Features: Manufacturing steel pipes by gradually reducing their diameter, usually at room temperature.

Advantages: It has high precision, high strength, and good corrosion resistance.

Application: Widely used in fields such as petroleum, chemical, aerospace, etc., especially suitable for situations with high performance requirements for steel pipes.

The choice of appropriate heat treatment method depends on actual needs. For example, for cost sensitive situations such as structural components and conveying pipelines, hot-rolled carbon steel pipes are a good choice; Cold rolled carbon steel pipes are more suitable for applications such as automobiles and household appliances that require high precision and surface quality; In situations such as petroleum and chemical industries that require high performance, cold drawn carbon steel pipes have more advantages.

By understanding these three different heat treatment methods of carbon steel pipes, users can better choose according to actual needs, ensuring the smooth progress of engineering or projects.

2.7 According To Application:

Carbon steel pipes can be classified according to their application scenarios, including boiler pipes, petroleum pipes, natural gas pipes, building structural pipes, mechanical manufacturing pipes, etc. Additionally, in terms of link usage, it is necessary to mention carbon steel pipe fittings. Carbon steel fittings: This category covers various fittings related to carbon steel pipe connections, fluid control, and regulating pipe shape changes. This includes elbows, flanges, tees, pipe caps, etc. to meet the different layouts and requirements of pipeline systems.

2.8 According To Material Status:

In the field of carbon steel pipes, Killed Carbon Steel Pipe and Semi Killed Carbon Steel Pipe are two common types of steel pipes that differ in production process, resulting in some differences in performance and application.

Firstly, let's understand the basic definitions of these two types of steel pipes.

Killed Carbon Steel Pipe, also known as "killed steel pipe", refers to steel pipes that have undergone "killed" treatment during the manufacturing process. This treatment makes the chemical composition of the steel pipe more uniform, thereby improving its mechanical properties. Killed steel pipes usually have good strength and toughness, and are suitable for various high-pressure and high-temperature environments.

In contrast, Semi Killed Carbon Steel Pipe, also known as "semi killed steel pipe", uses a special treatment method during the manufacturing process to make the internal structure of the steel pipe between killed steel and boiling steel. This semi killed steel pipe has good welding and processing properties and is widely used in fields such as construction, bridges, and ships.

From the perspective of production technology, there are also some differences between Killed Carbon Steel Pipe and Semi Killed Carbon Steel Pipe. In the production process of killed steel pipes, deoxidation treatment is usually carried out to reduce the oxygen content inside the pipes and prevent the formation of iron oxide. In the production process of semi killed steel pipes, the required mechanical properties are achieved by controlling the carbon content and adding appropriate alloying elements.

In practical applications, the selection of which type of carbon steel pipe should be based on specific needs. For example, for petroleum and chemical pipelines that need to withstand high pressure and temperature, Killed Carbon Steel Pipe is usually chosen. For structural engineering such as buildings and bridges, Semi Killed Carbon Steel Pipe is the preferred material due to its excellent welding and processing performance.

In summary, Killed Carbon Steel Pipe and Semi Killed Carbon Steel Pipe each have their own characteristics and application scope. For new users of steel pipes, it is essential to understand the performance and actual performance of these two types of steel pipes.

3. Composition of Carbon Steel Pipe

The main components of carbon steel pipes are iron and carbon, with a carbon content of approximately 0.06-1.5%. In addition, the chemical composition of carbon steel pipes also contains small amounts of the following elements, such as silicon, manganese, sulfur, phosphorus, nickel, aluminum, zinc, etc.

4. Carbon Steel Pipe Size

Carbon steel pipe size is typically wide. Generally, the diameter of circular carbon steel pipes can range from 10.3mm to 3620mm, with a wall thickness of 0.25-40mm and customizable lengths.

The outer diameter of square carbon steel pipes can range from 10 * 10 to 1200 * 1200mm, with a wall thickness of 0.25-60mm, and the length can be customized.

The outer diameter of rectangular carbon steel pipes can range from 10 * 15 to 800 * 1200mm, with a wall thickness of 0.25-60mm, and the length can be customized.

The specific specifications of carbon steel pipes can be downloaded from these links:

Carbon Steel Pipe Schedule Chart (specification sheet uploaded) Carbon Steel Pipe Catalog PDF (company brochure uploaded)

5.Carbon Steel Pipe Mechanical Properties

A. CS Pipe Tensile Strength

The tensile strength of carbon steel pipes is a crucial property, indicating their ability to withstand stretching forces without fracturing. It's a measure of the maximum stress a material can bear while being pulled. Carbon steel pipes, consisting primarily of iron and carbon, exhibit high tensile strength. This specific strength is influenced by the pipe grade, such as ASTM A53 or A106. Tensile strength is typically expressed in PSI or MPa. For instance, ASTM A106 Grade B pipes usually exhibit a minimum tensile strength of 60,000 PSI or 415 MPa. Recognizing this information is integral in selecting pipes suitable for diverse applications, ensuring they can endure the mechanical stresses they may encounter.

B. Carbon Steel Pipe Yield Strength

For carbon steel pipes, yield strength refers to the stress value at which the steel pipe begins to undergo yield deformation when subjected to a certain pressure or tension. It is one of the important performance indicators of carbon steel pipes. It reflects the ability of carbon steel pipes to resist permanent deformation when subjected to external forces. Generally speaking, higher yield strength means that pipelines have better load-bearing capacity and durability.

C. Impact Properties

The impact performance of carbon steel pipes actually refers to the behavior and performance of carbon steel pipes under impact or sudden external forces. This performance is crucial for understanding the toughness of materials and their ability to resist sudden fractures, especially in working environments that may be subjected to impact or vibration.

In many applications, such as oil and gas pipelines, chemical transportation systems, etc., carbon steel pipes may be affected by external impact forces or pressure fluctuations.

D. Carbon Steel Pipe Hardness

The hardness of carbon steel pipes actually refers to the indicator of their ability to resist external pressure or deformation. For carbon steel pipes, it is an important parameter for evaluating their mechanical properties and durability.

In the field of carbon steel pipelines, commonly used hardness testing methods include Rockwell hardness, Brinell hardness, and Vickers hardness.

6.Carbon Steel Pipe Thermal Properties

A. Heat Transfer Coefficient

The heat transfer coefficient is a parameter that measures the heat transfer capacity of a material per unit area per unit time. For carbon steel pipes, their heat transfer coefficient is influenced by various factors, including pipe thickness, temperature, surface treatment methods, etc. Understanding how these factors affect the heat transfer coefficient of carbon steel pipes can help engineers better select and use pipeline materials suitable for specific applications.

B. Melting Point

The melting point of carbon steel pipes refers to the temperature at which solid steel begins to transform into liquid. For ordinary carbon steel, the temperature is approximately 1371 to 1538 degrees Celsius. In industries such as welding or casting, accurate temperature control is crucial, especially when considering different steel alloy mixtures, where the exact melting point may vary. Therefore, understanding the melting point is crucial for ensuring the reliability of welds and pipeline structures.

In practical applications, the melting point of carbon steel pipes is also affected by the usage environment and working conditions.

C. Low-Temperature Limit

Do you understand the low-temperature limitations of carbon steel pipes? This refers to the minimum temperature at which carbon steel pipes can maintain stability without embrittlement in low-temperature environments. For most carbon steel pipes, the low temperature limit is between -20 ° F to -40 ° F (-29 ° C to -40 ° C). At lower temperatures, carbon steel pipes may become brittle, prone to cracking or damage. Therefore, it is very important to understand and comply with the low temperature restrictions of carbon steel pipes in extremely cold areas or in situations where they need to be used in low temperature environments. In this way, you can ensure that carbon steel pipes can maintain their stability and reliability in various extreme environments.

D. Working Temperature

When you need to determine the working temperature of carbon steel pipes, you first need to understand that the working temperature refers to the temperature that carbon steel pipes can withstand under normal operating conditions. For typical carbon steel pipes, their working temperature range is approximately -20°F to 212°F (-29°C to 100°C). Within this temperature range, carbon steel pipes can maintain their mechanical performance and structural integrity.

Beyond this working temperature range, carbon steel pipes may experience degradation or damage. For instance, at high temperatures, carbon steel pipes may soften, leading to a reduction in their mechanical performance. On the other hand, at low temperatures, carbon steel pipes may become brittle and prone to cracking. Therefore, understanding and adhering to the working temperature range of carbon steel pipes is crucial to ensure their performance and longevity.

7.Physical Characteristics

A. Weight Calculation ( Weight per Meter (kg/m))

Calculating the weight of a carbon steel pipe involves using the formula:

Weight (kg/m)=(Outside Diameter−Wall Thickness)/2×WallThickness×0.02466)×Length

This formula takes into account the outside diameter, wall thickness, and length of the pipe. To calculate the weight of a carbon steel pipe, subtract the wall thickness from the outside diameter, divide the result by 2, then multiply by the wall thickness and a constant factor (0.02466). Finally, multiply this by the length of the pipe to get the total weight in kilograms per meter. This method provides a straightforward way to determine the weight of a carbon steel pipe.

B. Density(carbon steel pipe density)

The density of carbon steel pipes is a key parameter in engineering applications. It determines the weight per unit volume and affects structural behavior and performance. The density range is 7.8 to 8.0 g/cm ³, It depends on the type and composition of the steel. This value is consistent across different sizes and wall thicknesses of the pipeline. Density is crucial for calculation and design considerations, such as weight, mass flow rate, and load estimation. Accurate knowledge ensures structural integrity and performance in various applications, including pipelines, water supply systems, and chemical plants.

C. Color

The color of carbon steel pipes depends on the surface treatment method. Normally, galvanized carbon steel pipes are silver or silver gray in color. Carbon steel pipes without any surface treatment are black gray. Carbon steel pipes that have undergone spray painting and anti-corrosion insulation treatment are usually painted or coated in the same color.

D. Shape

The shape of carbon steel pipes is usually circular, square, or rectangular, all of which have their unique advantages. Circular carbon steel pipes have high strength and stability, and can better withstand external pressure and impact. Square carbon steel pipes and rectangular carbon steel pipes are more flexible and can better adapt to different spatial requirements. In addition, the length of carbon steel pipes varies and can be cut and spliced according to actual needs. This flexible shape and size make carbon steel pipes widely used in various engineering and construction projects. Carbon steel pipes are one of the indispensable materials in bridge, construction, and pipeline engineering.

8. Carbon Steel Pipe Standards And Carbon Steel Pipe Grade

A. Carbon Steel Pipe Standards

Understanding the standards for carbon steel pipes is crucial to ensuring their quality and safety. The Carbon Steel Pipe Standard is a globally recognized set of guidelines specifying requirements for manufacturing, inspection, and labeling of carbon steel pipes. The Carbon Steel Pipe BS Standard, specific to the UK, is widely adopted in Europe and other regions. The Carbon Steel Pipe Indian Standard caters to the Indian market's needs. The ASTM Standard, established by the American Society for Testing and Materials, imposes stringent requirements on the quality and performance of carbon steel pipes. These standards ensure the consistency and reliability of carbon steel pipes, contributing to their safe and effective use. It is essential to be aware of and adhere to applicable standards when selecting carbon steel pipes.

B.Carbon Steel Pipe Grade

As a steel pipe user, it is very important to understand the Carbon Steel Pipe Grade, as different grades of carbon steel pipes have different mechanical properties and applicability. The classification of carbon steel pipes is based on their chemical composition, mechanical properties, and usage. The ASTM standard divides carbon steel pipes into different grades, such as A, B, C, D, etc., each grade has different uses and characteristics. For example, ASTM A53 grade carbon steel pipe is a common grade of carbon steel pipe suitable for general structural and pipeline applications. ASTM A106 grade carbon steel pipe is a high-grade carbon steel pipe suitable for high-temperature and high-pressure pipeline applications. As a seller, understanding different grades of carbon steel pipes can better meet customer needs and provide appropriate product recommendations. Meanwhile, compliance with applicable carbon steel pipe grade standards is also crucial to ensuring product quality and safety.

9. Life and Corrosion Resistance

A.Corrosion Resistance

Firstly, let's understand the corrosion resistance of carbon steel pipes. The corrosion of carbon steel pipes is mainly influenced by Corrosion Mechanisms, including chemical corrosion and electrochemical corrosion. In order to improve the corrosion resistance of carbon steel pipes, we can enhance their corrosion resistance by selecting appropriate pipes, coating protection, surface treatment and other measures.

In addition, the corrosion resistance of carbon steel pipes is also related to their surface roughness. Internal roughness is an important indicator for evaluating the quality of carbon steel pipes. Generally speaking, the lower the internal roughness of carbon steel pipes, the better their corrosion resistance. Therefore, when choosing carbon steel pipes, we need to pay attention to the size of their internal roughness and choose appropriate coating protection measures to improve their corrosion resistance.

At the same time, we also need to understand the Corrosion Allowance of carbon steel pipes. Corrosion allowance refers to the degree of corrosion that carbon steel pipes can withstand during use. Different usage environments and medium characteristics have different requirements for the corrosion allowance of carbon steel pipes. Therefore, when selecting carbon steel pipes, we need to determine the size of their corrosion allowance based on the actual situation to ensure their safe and effective use.

Finally, we also need to focus on Coated Carbon Steel Pipes and Lined Pipes for carbon steel pipes. These internal coatings or linings of pipes can further improve the corrosion resistance and service life of carbon steel pipes. At the same time, we also need to understand parameters such as Coated Carbon Steel Pipe Absolute Roughness and Internal Roughness to ensure the quality and effectiveness of the coating or lining.

B.Life Of Carbon Steel Pipe

The lifespan of carbon steel pipes depends on multiple factors, such as pipe quality, usage environment, maintenance, etc. Under normal conditions, high-quality carbon steel pipes can have a lifespan of several decades or even hundreds of years. To ensure the service life of carbon steel pipes, we need to carry out appropriate maintenance and upkeep, including regular inspections, cleaning, coating protection, etc.

10. How Much Does Carbon Steel Pipe Cost?

Firstly, let's understand the cost and price of carbon steel pipes. At present, the cost of carbon steel pipes is mainly affected by the raw material prices of carbon steel coils and carbon steel plates. In addition, the price of carbon steel pipes is also affected by the following factors, such as the specifications, length, thickness, quality level, surface treatment, etc. of the pipes. Generally speaking, high-quality carbon steel pipes are relatively expensive, but have a longer service life and more stable performance.

Next, let's talk about the factors that affect the price of carbon steel pipes. Firstly, specifications and length are one of the important factors affecting the price of carbon steel pipes. Generally speaking, carbon steel pipes with larger diameters and longer lengths are more expensive. This is because large-sized pipes require thicker steel plates and more complex production processes, resulting in higher costs. Secondly, quality level is also one of the important factors affecting prices. High quality carbon steel pipes require higher manufacturing processes and stricter quality control, therefore their prices are relatively high. In addition, surface treatment is also one of the important factors affecting prices. Common surface treatment methods include galvanizing, spraying, coating, etc., and different surface treatment methods also have different impacts on prices.

So, how much does carbon steel pipe cost? In fact, it is difficult to provide a specific cost figure for carbon steel pipes because they are influenced by multiple factors. However, we can roughly estimate the cost of carbon steel pipes by understanding factors such as their composition, specifications, quality level, and surface treatment. When purchasing carbon steel pipes, we also need to consider other factors such as transportation costs, installation costs, etc. Therefore, the final price still needs to be determined based on the actual situation.

11. Processing Method Of Carbon Steel Pipe

A. Cutting

Now let me talk to you about the cutting of carbon steel pipes. Cutting carbon steel pipes may seem simple, but in fact, many details need to be paid attention to, especially in the industrial and construction fields. The accuracy and quality of cutting directly affect subsequent construction and safety.

Firstly, we need to understand that unlike plastic or copper pipes, carbon steel pipes are a material with high hardness and strength, and therefore require the use of specialized cutting tools. Among them, the carbon steel pipe cutter is one of the most commonly used tools. This type of cutter is well-designed and can quickly and accurately complete cutting tasks.

So, how to use carbon steel pipe cutters correctly? Firstly, we need to choose the appropriate cutter specifications, based on the diameter and thickness of the carbon steel pipe. Then, fix the carbon steel pipe on a stable workbench to ensure that there is no shaking or movement during the cutting process. Next, adjust the blade position of the cutter to make it tightly adhere to the surface of the carbon steel pipe. Finally, start the cutter and slowly push the handle to make the blade cut on the surface of the carbon steel pipe.

I have written another article about the cutting of steel pipes. Please refer to this article to learn more about steel pipe cutting.

B. Welding

Firstly, we need to understand that welding carbon steel pipes is not a simple task, it requires strict operating procedures and technical requirements. When we talk about the carbon steel pipe welding procedure, we are actually discussing a systematic project that involves multiple steps and considerations.

So, first of all, let's talk about "how to weld carbon steel pipe?".

Preparation stage: This is a crucial part of any welding work. For carbon steel pipes, we first need to ensure the cleanliness of the pipes. Any residual dust, oil stains, or rust may affect the welding quality. Therefore, we need to use appropriate cleaning agents and tools to remove these impurities.

Matching welding wires: Choosing the correct welding wire is crucial. The chemical composition of the welding wire must match the material of the carbon steel pipe to ensure that the welded joint has good mechanical properties.

Preheating: In some cases, preheating carbon steel pipes is necessary. Preheating can reduce stress during the welding process and prevent the formation of cracks.

Welding process: This stage requires proficient operational skills. We use appropriate welding equipment and operate according to the specified welding parameters. The parameters include current, voltage, and welding speed, all of which can affect the welding quality.

Post weld treatment: After welding is completed, we need to conduct a series of quality inspections. In addition, heat treatment or stress relief processes may be required as needed.

Through the above steps, we can complete the welding of carbon steel pipes. However, it should be noted that each step requires strict operating procedures and technical requirements to achieve the best welding effect.

C. Bending

When we talk about "carbon steel pipe bending radius" and "carbon steel pipe bends", we are actually exploring an engineering challenge and art. The bending of carbon steel pipes involves material characteristics, process technology, and practical applications.

Firstly, let's talk about the bending radius of carbon steel pipes.

The bending radius of carbon steel pipes determines the degree to which they can be bent. Carbon steel pipes of different specifications and materials have different bending radii. Generally speaking, thinner pipes have a smaller bending radius, while thicker pipes require a larger bending radius. This is because thinner pipes are more prone to yielding when bent, while thicker pipes require greater force to bend.

Next, we will delve into the bending process of carbon steel pipes.

The bending process of carbon steel pipes requires precise operation and control. Firstly, we need to choose an appropriate bending radius to ensure that the pipe does not undergo excessive deformation or damage during the bending process. Then, we can use tools such as pipe bending machines or hydraulic pipe benders for bending operations. During the bending process, we need to pay attention to controlling the bending speed and torque to avoid excessive stress or strain on the pipe during the bending process.

In addition, to ensure the bending quality and safety of carbon steel pipes, we also need to pay attention to the following points:

Ensure that the pipes have undergone appropriate pre-treatment before bending, such as cleaning, rust removal, and coating protection.

Choose appropriate bending methods and tools based on the specifications and materials of the pipes to avoid excessive deformation or damage.

During the bending process, the temperature and deformation of the pipe should be monitored at all times. If there are any abnormalities, the operation should be stopped in a timely manner and adjustments should be made.

After completing the bending, quality inspection and testing should be carried out to ensure the bending quality and safety of the pipe.

Through the above introduction, I believe you have gained a deeper understanding of the bending methods and processes of carbon steel pipes. In practical applications, mastering the correct operating methods and precautions is crucial to ensure that carbon steel pipes can safely and effectively complete the bending process.

D. Joining Methods

When we talk about carbon steel pipe joining methods, we are actually exploring how to safely and effectively connect two or more carbon steel pipes together. There are many methods for connecting carbon steel pipes, each with its unique advantages and applicable scenarios.

Firstly, we need to clarify that selecting the correct connection method is crucial for the installation and use of carbon steel pipes. The reliability, strength, and durability of connections directly affect the performance and safety of pipeline systems.

Welding: Welding is a common method of connecting two pipes together through molten metal. Carbon steel pipe welding requires proficient skills and specific tools to ensure the quality of the connection. Quality inspection and appropriate post-processing after welding are also essential.

Flange connection: flange connection is a common mechanical connection method. In this method, one or two pipe ends with flanges are inserted into another fitting and secured together by bolts or other fasteners. The advantage of flange connection is that it is easy to install and disassemble, and is suitable for situations that require frequent disassembly or maintenance.

Socket connection: Socket connection is a simple and common connection method suitable for carbon steel pipes with smaller diameters. In this method, the end of one pipe is inserted into the end of another pipe, and then fixed together by filling or welding. The advantages of socket connections are simplicity, speed, and economy.

Adhesive: For certain specific applications, adhesive can be used to connect carbon steel pipes. Adhesives can be special adhesives or sealants, suitable for situations that require high sealing and pressure resistance. The advantage of bonding is that it is fast and does not require special tools, but attention should be paid to the selection and usage conditions of the adhesive.

Thread connection: Thread connection is an ancient and reliable connection method. In this method, the end of the pipe is machined into a threaded shape and then tightly connected to another fitting or joint with the corresponding thread. The advantages of threaded connections are high strength and good sealing, but they require special tools and processing techniques.

Regardless of which connection method you choose, you need to pay attention to the following points:

>Ensure the cleanliness and flatness of the pipe ends to achieve good connection results.

>Follow the manufacturer's recommendations and instructions, and use the correct tools and materials for installation.

>Conduct necessary inspections and tests to ensure the quality and safety of the connections.

Through the above introduction, I believe you have gained a deeper understanding of the connection methods and processes of carbon steel pipes. In practical applications, selecting appropriate connection methods and strictly adhering to operating procedures are crucial to ensure the performance and safety of pipeline systems.

E. Coating

When we talk about coated carbon steel pipes, we are actually exploring how to improve the corrosion resistance, wear resistance, and other special properties of carbon steel pipes through coating technology. Coating technology is widely used in the production and processing of carbon steel pipes to enhance their performance and lifespan.

Carbon steel pipe epoxy coating

Epoxy coating is a common coating for carbon steel pipes, which has excellent corrosion resistance and wear resistance. Epoxy coatings are usually composed of epoxy resin, curing agents, and other additives, forming a protective film on the surface of carbon steel pipes through electrostatic spraying or spray coating. The advantages of epoxy coatings are strong adhesion, excellent chemical corrosion resistance, and good mechanical properties and durability. However, the disadvantage of epoxy coatings is their high cost and sensitivity to temperature and humidity, which may pose a risk of cracking or peeling.

Carbon steel pipe internal coating

Internal coatings are mainly used to protect the interior of pipelines from fluid corrosion and other substances. Internal coating materials typically include anti-corrosion coatings, plastic coatings, and glass flake coatings. The advantage of inner coating is that it can effectively isolate the inner wall of the pipeline from the conveying fluid, prevent corrosion and scaling problems. In addition, the inner coating can also improve the flow performance of pipelines and reduce fluid resistance. However, the disadvantage of the inner coating is that it may affect the welding and connection of the pipeline, and regular inspection and maintenance are required to ensure its integrity.

"Fbe lined carbon steel pipe"

FBE (Fluorinated Ethylene Propylene) lining is a thermoplastic elastomer used to enhance the corrosion resistance and mechanical properties of carbon steel pipes. FBE lined carbon steel pipes have excellent chemical corrosion resistance, high wear resistance, and good mechanical strength. The FBE lining can tightly bond with carbon steel pipes, forming a strong protective layer that effectively prevents the erosion of various chemical media. In addition, FBE lining also has excellent anti-aging and high-temperature resistance, which can maintain stability in harsh environmental conditions. However, the disadvantage of FBE lining is its high cost and the need for special processes and techniques during the processing.

Hot dip galvanized carbon steel pipe

Hot dip galvanizing is a common coating technology for carbon steel pipes, which involves immersing the steel pipe in a molten zinc bath to attach the zinc layer to the surface of the steel pipe, forming a protective layer. The advantage of hot-dip galvanized coating is its excellent corrosion resistance and rust prevention, which can effectively protect steel pipes from environmental factors such as atmosphere, water, and soil erosion. At the same time, the hot-dip galvanized layer also has good adhesion and mechanical strength, which can provide good protection and support.

However, hot-dip galvanized carbon steel pipes also have some drawbacks. Firstly, the thickness and quality of hot-dip galvanized coatings are influenced by process parameters and may require strict quality control. Secondly, the cost of hot-dip galvanized coating is relatively high, which may increase the cost of the entire pipeline system. In addition, the hardness and brittleness of hot-dip galvanized coatings are relatively high, which may cause certain limitations on the bending and processing of pipelines.

Zinc aluminum magnesium coated carbon steel pipe

Zinc aluminum magnesium is a new type of carbon steel pipe coating technology, which forms a composite coating by immersing the steel pipe in an alloy bath containing aluminum, magnesium, and zinc. The advantage of zinc aluminum magnesium coating is its excellent corrosion resistance and rust prevention, which can provide longer protection than traditional hot-dip galvanized coatings. In addition, the zinc aluminum magnesium coating also has good adhesion and mechanical strength, which can provide good protection and support.

Compared with hot-dip galvanized carbon steel pipes, zinc aluminum magnesium carbon steel pipes have some advantages. Firstly, the hardness and brittleness of the zinc aluminum magnesium coating are relatively small, making it more friendly for pipeline bending and processing. Secondly, zinc aluminum magnesium coatings have stronger corrosion resistance and can provide longer protection periods. In addition, the cost of zinc aluminum magnesium coating is relatively low, which may reduce the cost of the entire pipeline system.

However, zinc aluminum magnesium carbon steel pipes also have some drawbacks. Firstly, the process parameters of zinc aluminum magnesium coating are relatively complex and require strict quality control. Secondly, compared to traditional hot-dip galvanized coatings, the adhesion and mechanical strength of zinc aluminum magnesium coatings may be slightly insufficient. Therefore, it is necessary to pay attention to processing and installation requirements during use to ensure the integrity and protective effect of the coating.

In summary, there are multiple options for coating technology of carbon steel pipes, each with its unique advantages and applicable scenarios. When selecting a suitable coating, it is necessary to consider the specific application requirements, environment, and medium conditions comprehensively. Meanwhile, the correct painting process and maintenance are also important factors in ensuring the quality and lifespan of coatings. By understanding this information, users can better choose and use carbon steel pipe coating products that are suitable for their needs.

12. Applications

When we talk about "carbon steel pipe uses", we are actually exploring the practical applications of carbon steel pipes in various fields. Carbon steel pipes are widely used in various industrial, construction, and civil fields due to their excellent performance and wide applicability.

Firstly, let's talk about the application of carbon steel pipes in the field of water supply.

Carbon steel pipes play an important role in the field of water supply, mainly used for transporting drinking water and treating sewage. Due to its excellent corrosion resistance and strength, carbon steel pipes can ensure the safety and reliability of water quality. In water supply systems, carbon steel pipes are used to connect water sources and users, as well as to transport and treat sewage in sewage treatment facilities. When selecting carbon steel pipes, factors such as pressure resistance, corrosion resistance, and fluid compatibility need to be considered to ensure the long-term stable operation of the system.

Next, we will explore the application of carbon steel pipes in the field of natural gas transportation.

Carbon steel pipes are widely used in natural gas transportation pipeline systems. The transportation of natural gas requires high-strength pipeline materials, and carbon steel pipes have good mechanical properties and corrosion resistance, which can withstand high pressure and chemical corrosion of gases. In natural gas pipeline systems, carbon steel pipes are used to connect gas fields and users, ensuring the safe and efficient transportation of natural gas. When choosing carbon steel pipes, factors such as compressive strength, toughness, and corrosion resistance need to be considered to adapt to different geographical environments and climatic conditions.

In addition, carbon steel pipes are also widely used in the construction field.

In the field of construction, carbon steel pipes are mainly used in building water supply and drainage systems and HVAC systems. Carbon steel pipes have good corrosion resistance, strength, and plasticity, and can withstand the heavy pressure of buildings and the pressure of fluid transportation. In building water supply and drainage systems, carbon steel pipes are used to transport domestic water and treat sewage; In HVAC systems, carbon steel pipes are used to transport heat and cold energy, providing a comfortable temperature and humidity environment for buildings. When selecting carbon steel pipes, factors such as pressure resistance, fluid compatibility, and installation convenience need to be considered to ensure the normal operation and service life of the system.

In addition, carbon steel pipes are widely used in fields such as petrochemicals, electricity, ships, and aviation.

In these fields, the high strength, corrosion resistance, and good processing performance of carbon steel pipes have been widely applied. For example, in the field of petrochemicals, carbon steel pipes are used to transport oil products and chemical raw materials; In the field of electricity, carbon steel pipes are used to manufacture chimneys, thermal pipelines, and steam pipelines; In the fields of ships and aviation, carbon steel pipes are used to manufacture fluid pipelines and support structures. In these fields, when selecting carbon steel pipes, factors such as corrosion resistance, strength, and wear resistance need to be considered to ensure the safety and reliability of the system.

In summary, carbon steel pipes have a wide range of applications in fields such as water supply, natural gas transportation, construction, petrochemicals, electricity, shipbuilding, and aviation. The selection of suitable carbon steel pipes requires comprehensive consideration based on specific application scenarios, fluid media, and environmental conditions. In addition to considering performance requirements, factors such as cost, installation, and maintenance also need to be considered. By understanding this information, users can better choose and use carbon steel pipe products that are suitable for their needs.

13.Difference With Other Steel Pipes

In the field of construction and engineering, the selection of pipelines is crucial as it directly affects the safety and durability of the project. There are various types of pipelines on the market, each with its unique characteristics and application scenarios. Among them, there are significant differences in material, usage, and performance between carbon steel pipes and MS pipes and GI pipes.

GI Pipe VS Carbon Steel Pipe

GI pipes, also known as galvanized steel pipes, are commonly used in indoor water supply and fire protection systems. Its advantage lies in its good anti-corrosion performance, which can be used for a long time in outdoor environments. However, the strength and pressure resistance of GI pipes are relatively low. Carbon steel pipes are superior to GI pipes in terms of strength, corrosion resistance, and pressure resistance. In addition, the connection methods of carbon steel pipes are more diverse, which can adapt to various complex installation needs.

MS Pipe VS Carbon Steel Pipe

MS pipes, also known as cast iron pipes, are commonly used in water supply and drainage systems. It has good corrosion resistance and can be used for a long time in acidic or alkaline environments. However, MS pipes are not as strong and durable as carbon steel pipes. In contrast, carbon steel pipes are composed of carbon and a small amount of other alloying elements, which have higher mechanical strength and pressure resistance. This means that carbon steel pipes can withstand greater pressure and are suitable for high-pressure fluid transmission, such as oil or natural gas.

Advantages And Disadvantages Of Carbon Steel Pipes

The advantages of carbon steel pipes are mainly reflected in the following aspects:

High strength and pressure resistance: Due to its high carbon content and the addition of other alloying elements, carbon steel pipes have excellent mechanical properties and can withstand high-pressure fluids.

Good weldability: Carbon steel pipes can be connected through various methods, such as welding, threaded connections, etc., which makes them very suitable for situations that require long-term stable operation.

Widely applicable fields: From oil and gas transmission to water supply and drainage systems, to chemical process flow, carbon steel pipes are capable of handling everything.

However, carbon steel pipes also have some shortcomings:

High cost: Compared to some other types of pipelines, the price of carbon steel pipes may be higher. This is mainly due to the high technical requirements and material costs in its production process.

Professional installation and maintenance are required: Due to the special performance of carbon steel pipes, they need to be installed and maintained by professional personnel to ensure their long-term stable operation.

Sensitive to environmental conditions: In some corrosive environments, carbon steel pipes may face a faster corrosion rate and require additional anti-corrosion measures.

In summary, carbon steel pipes have significant advantages compared to other types of pipelines, but there are also some shortcomings. The choice of pipeline should be determined based on specific application scenarios and requirements. In situations where high-pressure fluid transmission or high mechanical performance requirements are required, carbon steel pipes are undoubtedly a more suitable choice. In cost sensitive or corrosion-resistant situations, other types of pipelines may need to be considered.

Conclusion:

Carbon steel pipes are key components in various engineering fields. Its excellent strength and pressure resistance make it widely used in fields such as oil, natural gas, and water supply systems. However, at the same time, the cost of carbon steel pipes is relatively high and they are sensitive to certain environmental conditions.

With the advancement of technology, we expect carbon steel pipes to have more optimization and development. New materials and processes may further enhance their performance and expand their application scope.

But no matter how the future changes, understanding the basic knowledge of carbon steel pipes is always the foundation. Understanding its performance, application scope, and limitations can help us choose and use it more effectively.

I hope this simplified introduction can help you better understand carbon steel pipes and provide reference for your engineering practice.

FAQ:

1.Carbon Steel Pipe Becomes Brittle Below What Temperature?

Carbon steel pipes tend to become brittle in low temperature environments, typically at temperatures below -20 ° C (-4 ° F). In extremely cold conditions, carbon steel pipes may become very brittle and prone to cracking. Therefore, when installing carbon steel pipes in cold regions or outdoors, it is necessary to consider the low-temperature adaptability of the pipes and take appropriate insulation measures to prevent them from becoming brittle and cracking due to low temperatures. Meanwhile, it is recommended to refer to relevant specifications and standards when designing and installing carbon steel pipes to ensure the safety and reliability of the pipelines.

2.Carbon Steel Pipe Burst Pressure

The burst pressure of carbon steel pipes depends on factors such as their manufacturing process, material thickness, and specifications. Generally speaking, the burst pressure of carbon steel pipes depends on their maximum working pressure and pipe wall thickness. When selecting carbon steel pipes, it should be ensured that they have sufficient strength and thickness to withstand the required pressure and comply with relevant standards and specifications. Meanwhile, when using carbon steel pipes, safety operating procedures should be followed to avoid overpressure operations and prevent the occurrence of explosion accidents.

3.Carbon Steel Pipe Expansion Calculator

The expansion coefficient of carbon steel pipes can be calculated based on their manufacturing materials and processes. Generally speaking, the coefficient of expansion of carbon steel pipes depends on factors such as manufacturing materials, temperature, and pressure. When using carbon steel pipes, the impact of their expansion coefficient on the pipeline system should be considered, and corresponding measures should be taken to prevent pipeline deformation or rupture. Meanwhile, it is recommended to use a professional carbon steel pipe expansion coefficient calculator or consult a professional engineer to obtain accurate calculation results and solutions.

4.Carbon Steel Pipe Emissivity

The emissivity of carbon steel pipes refers to the characteristic of the surface radiation energy of the material, usually expressed in Greek letters ε Represent. The emissivity of carbon steel pipes depends on their surface condition and coating treatment. Generally speaking, uncoated carbon steel pipes have lower emissivity, while coated carbon steel pipes can have different emissivity values depending on the coating. Improving the emissivity of carbon steel pipes can facilitate better heat exchange with the surrounding environment and improve heat transfer efficiency. Therefore, in practical applications, selecting carbon steel pipes with appropriate emissivity and applying appropriate coating treatment can optimize heat transfer efficiency and energy utilization efficiency.

5.Can Carbon Steel Pipe Be Used For Acidic Water?

Carbon steel pipes can be used for transporting acidic water, but their corrosion resistance and overall design of the pipeline system need to be considered.

Carbon steel pipes have certain acid resistance and can withstand a certain concentration of acidic water. However, prolonged exposure to high concentrations of acidic water may lead to corrosion of carbon steel pipes, affecting their service life. Therefore, when using carbon steel pipes to transport acidic water, appropriate anti-corrosion measures need to be taken, such as using anti-corrosion coatings or lining, to protect the pipeline from corrosion.

In addition, it is necessary to consider the overall design of the pipeline system to ensure that acidic water does not cause corrosion or damage to other components in the pipeline system. Meanwhile, it is recommended to conduct relevant corrosion tests and risk assessments before using carbon steel pipes to transport acidic water, in order to ensure the safety and reliability of the pipeline system.