Can the strength of steel be superimposed?

Decoding Steel Strength: Can it Really Stack Up?

Recently, an ingenious engineer claimed that stacking two 1,500-megapascal hot-formed steel plates is equivalent to a single 3,000-megapascal hot-formed steel plate, sparking discussions among netizens.

Some analogies were thrown around, like pouring two cups of 50-degree hot water together and questioning if it becomes 100 degrees. Others humorously asked about the hardness of one chopstick versus two. These comparisons sound amusing, but in reality, the situation is not that straightforward. As a "steel person," let me shed some light on this.

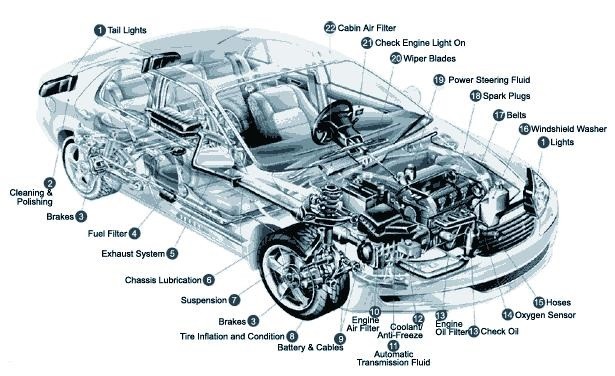

Firstly, let's understand the concept of steel strength. 1,500 megapascals is a unit of pressure, more precisely known as megapascal pascals. Strength refers to a material's ability to resist deformation and rupture, and megapascals quantify this strength. To evaluate a car's safety, we need to consider both active and passive aspects, such as seat belts, airbags, and body structure.

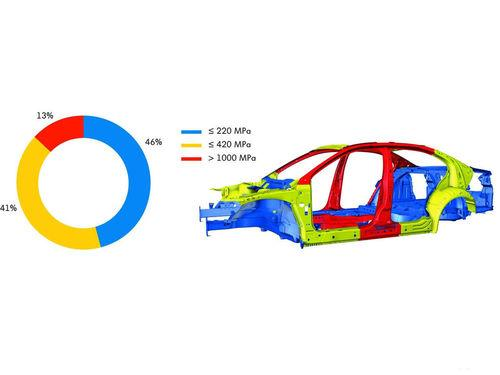

Currently, mainstream automakers use a cage-type body structure, likening the car cabin area to a birdcage, providing all-around protection for the driver and passengers. The strength of the steel used to construct the cage-type body determines how robust the vehicle is. Most cars use higher-strength hot-formed steel in areas like the A and B pillars and crossbeams. Hot-formed steel involves heating a regular steel plate to 950 degrees, followed by hot stamping forming, and finally rapid cooling. The strength of hot-formed steel is several times higher than that of regular steel. Typically, the strength of hot-formed steel in cars exceeds 1,300 megapascals, with some models reaching up to 2,000 megapascals. Hot-formed steel is not only applied in the automotive industry but is also widely used in aerospace, defense, construction, and other fields.

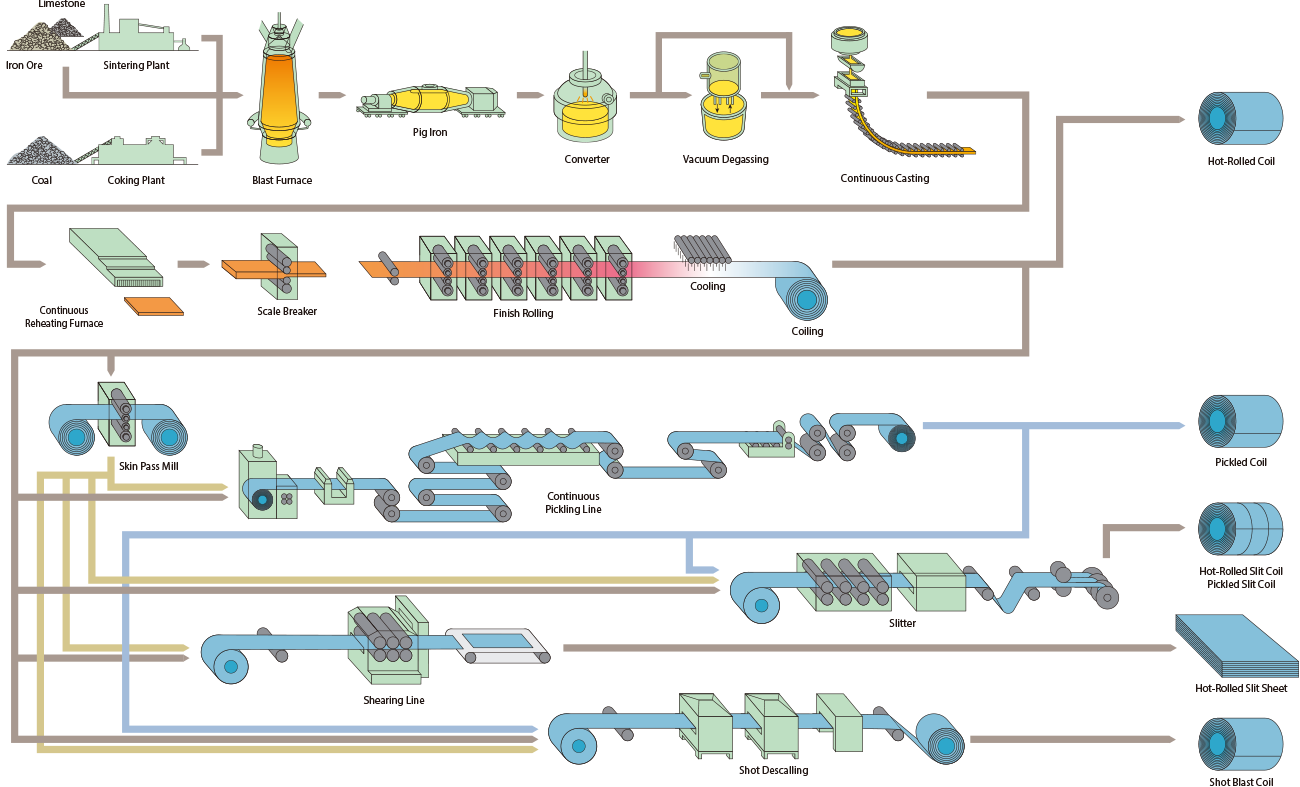

Hot formed steel manufacturing process

So, what about other parts of the car? Generally, lower-strength steel is used in those areas. This is why car manufacturers always highlight the percentage of hot-formed steel used in their vehicles. Since hot-formed steel is so powerful, why not use it to build the entire car body? Well, it's not that simple. On one hand, the cost of hot-formed steel is higher, and on the other hand, it's related to the design of the body structure.

Someone presented an analogy, putting an egg in an iron box and tossing it on the ground. The iron box remains intact, but the egg inside will definitely break. However, if you wrap the outside of the iron box with a thick layer of sponge and then throw it on the ground, the egg inside won't break. The same principle applies to cars. The passengers inside are like the egg. The cage-type body, made with hot-formed steel, is the iron box, while other lower-strength energy-absorbing zones on the car body act like the sponge. During a collision, the energy-absorbing zones absorb most of the impact energy, with only a small amount transferring to the cabin. Therefore, in some accidents, the front of the car may be completely destroyed, but the driver remains unharmed. If the safety strength of the passenger cabin is insufficient, the collision impact could affect the driver, causing more severe injuries.

In conclusion, going back to the initial question in the video, does stacking two 1,500-megapascal steel plates together equate to a single 3,000-megapascal steel plate? The answer is a definite no. It's like reinforcing a building with steel bars; the strength of two bars is not double the strength of one but 1.4 times. While marketing tactics may seem exaggerated, they genuinely bring in remarkable attention.

These examples emphasize that when discussing issues, it's not sufficient to rely on analogies and imagination; understanding relevant physical knowledge and underlying principles is crucial. So, can steel strength really be stacked? The answer is not equal to,the strength of steel cannot be superimposed. That requires us to delve deeper into the mysteries of steel!